Loading... Please wait...

Loading... Please wait...Categories

NEWSLETTER

Testimonials

To Ponder

Low Velocity & Micro Flow Measurement in Open Channels

Application Challenge

Accurately measuring water flow in open channels that exhibit very slow velocity is a major challenge for most technologies. Velocities less than 0.5 feet per second are extremely difficult to reliably measure until now.

Two of the typical applications that we see which often exhibit low velocities are:

- Sewer collection system: small pipe sizes with low volume, low pipe slope, and locations with downstream issues causing backup of water. Often the water level is below 1 inch which creates additional challenges for most technologies that have a minimum required water level.

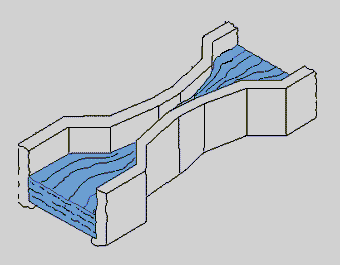

- UV disinfection & chlorine contact channels: these are usually larger rectangular channels with very slow moving water to provide required contact time. Level is generally high and constant.

Typical Options

Flumes & Weirs

Flumes and weirs can be a good choice for low flows and velocities if space allows and if the approach and flow conditions are within design range. Depending on the model and size, they can have issues passing solids.

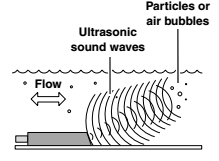

Submerged or “Wetted” Area Velocity sensors

This type of sensor is typically mounted on a spring ring or plate with the sensor located at the bottom of the channel. In order to measure velocity, they need a minimum level of 1 inch, and for velocity “profilers” it is much more. This type of sensor is an obstruction to the flow especially at low level and prone to ragging.

Surface Only Velocity & Non-Contact

There are several sensors that are mounted above the water, and hence non-contact. The obvious advantage is nothing is in the water to disturb the measurement at low levels. Sensors that use Radar, Ultrasonic, and Microwave technologies can only measure the speed of the water surface, and only if there are enough “ripples” to get returned signals. At low velocities the surface is normally very smooth. Therefore, these technologies have difficulty below 1 foot per second. More importantly, they assume a consistent and uniform flow profile below the surface which often isn’t true especially as level changes and silting occurs.

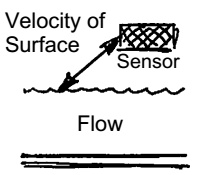

Recommended Solution: Sub-Surface Multi-Point Velocity & Non-Contact

The Teledyne ISCO LaserFlow® is mounted above the water surface and as such is non-contact so there are no induced errors at low levels. Due to its use of a water penetrating Laser beam, it has the distinct advantage that it measures the water velocity sub-surface and at multiple locations in the measurement plane.

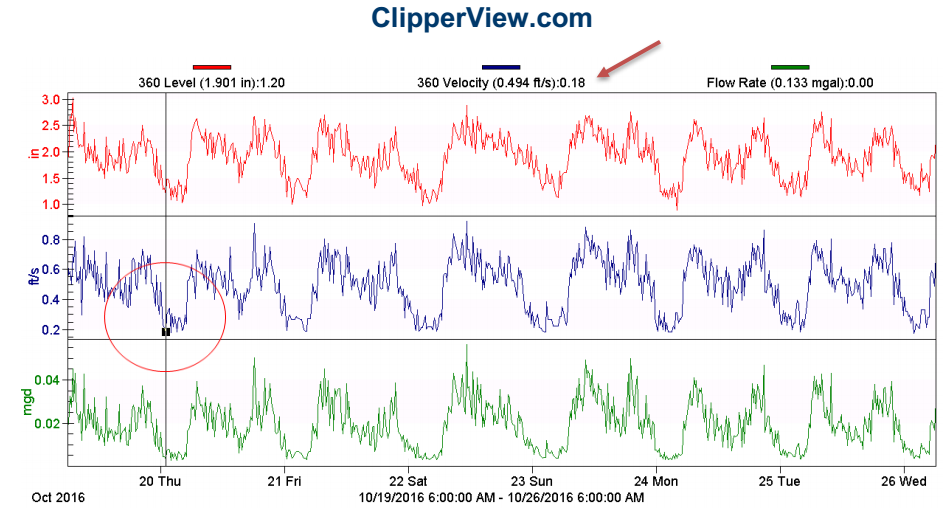

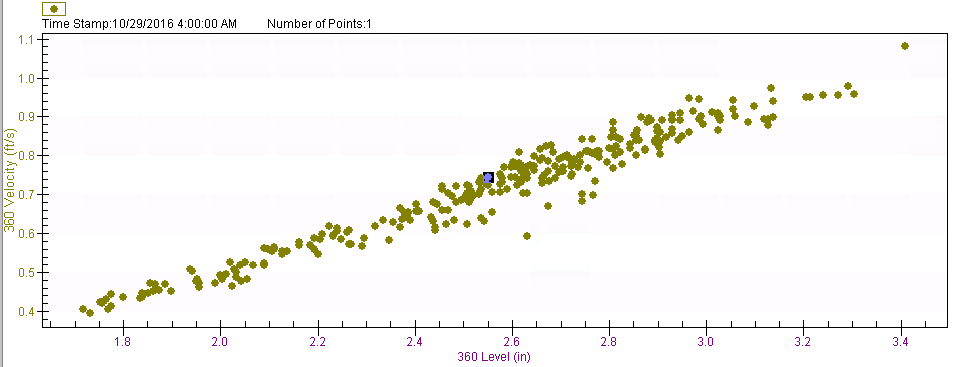

Measuring velocity with a Laser is extremely sensitive and accurate. The current published minimum velocity is 0.5 fps, but we are routinely measuring below 0.3 fps. By making some adjustments in the advanced setup tab of the software we have customers measuring as low as 0.18 fps as shown in the site graph below. The data below is a 6 inch sewer line.

Since the beam angle of the Laser is pin-point, it can easily measure velocity in pipes as small as 4”. The pipe size is only limited by the ultrasonic level sensor beam angle.

We can confirm the validity of the LaserFlow® reported velocity values in several ways:

- A simple plausibility check using a scattergraph of level vs velocity is useful if the flow conditions are normal.

Scattergraph

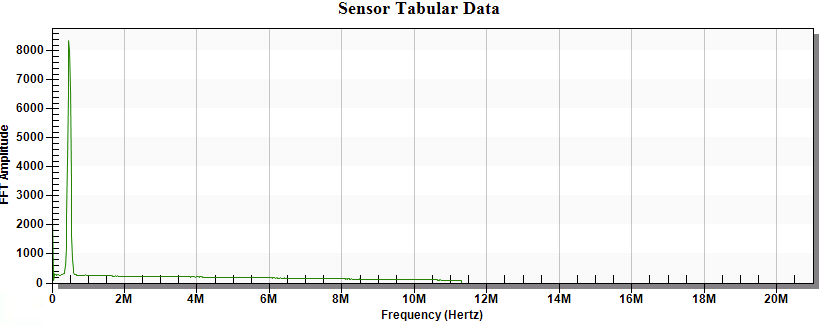

- The velocity reading reported by the LaserFlow® is actually determined by comparing ~6000 velocity readings during the 2 seconds the Laser is activated at the specific depth and angle. How well these readings correlate is called the Doppler Power, and anything above 1000 is excellent correlation. Notice the peak at the low velocity in the graph below, and how distinctive it is.

Doppler Power

- In addition the returned signal strength is measured along with numerous other diagnostics such as optical clarity of the lens, various temperatures, and X/Y position of the sensor. If any of these parameters are out of range an error will be indicated.

Summary

The LaserFlow® brings a whole new level of capability to accurately measure the challenging applications that include very low velocities and micro-flows due to:

- Sub water surface velocity measurements with pin-point accuracy

- Non-Contact sensing resulting in no impact on flow at low water levels & immunity to buildup

- Laser accuracy and sensitivity

- Multiple methods to validate data

- Fast response time to handle rapidly fluctuating flows