About Flow Optimizers

Flow Optimizers, LLC is a Minority and Woman-Owned hydraulic engineering and manufacturing firm based in Lizella, Georgia. Founded in 2017, the company specializes in designing, engineering, and fabricating inlet flow conditioning solutions for pump and meter systems. Their products serve a wide range of industries including water and wastewater, power, oil and gas, agriculture, chemical processing, pharmaceuticals, food and beverage, and pulp and paper.

Flow Optimizers offers an extensive product portfolio, including flow conditioning baskets, vaned spools, floor cones, bellmouths, vaned tees and crosses, reducing elbows, eccentric reducers, wall vanes, and pump suction extension tubes. These components are engineered to eliminate turbulence, suppress vortices, and ensure smooth, uniform flow profiles in challenging system layouts.

The company utilizes advanced hydraulic modeling and in-house manufacturing capabilities—such as CNC machining, laser and waterjet cutting, robotic welding, and precision finishing—to produce high-performance stainless steel (316L, NSF-61 compliant) equipment. Flow Optimizers is AS9100D/ISO-9001 certified, SBA 8(a) certified, EDWOSB/WOSB certified, ITAR-registered, and a member of the Hydraulic Institute.

By optimizing inlet flow conditions, their solutions improve pump efficiency, increase flow meter accuracy, reduce energy consumption, and minimize issues such as noise, vibration, and cavitation. All products are proudly designed and manufactured in the USA, delivering engineered reliability and value for demanding pump applications.

Product Categories

Product Families

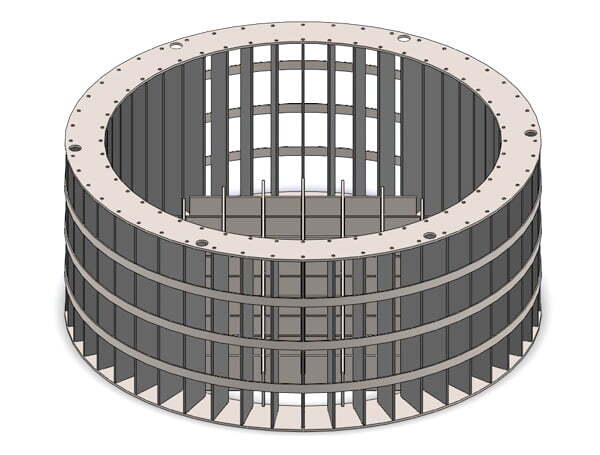

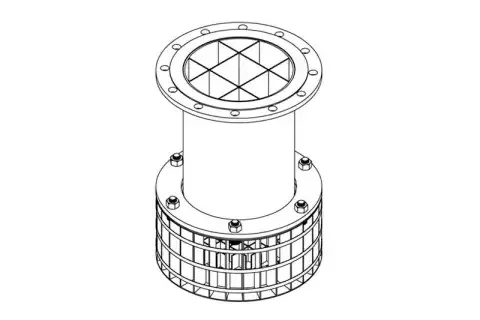

Flow Conditioning Basket

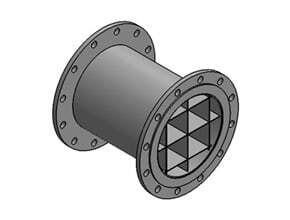

Flow Straightening Spool

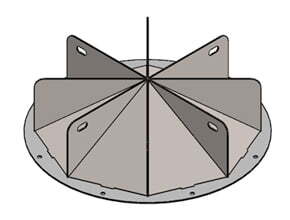

Flow Conditioning Suction Cone

Vaned Tee Flow Conditioner

Flow Conditioning Suction Bell

Handhole Cleanout

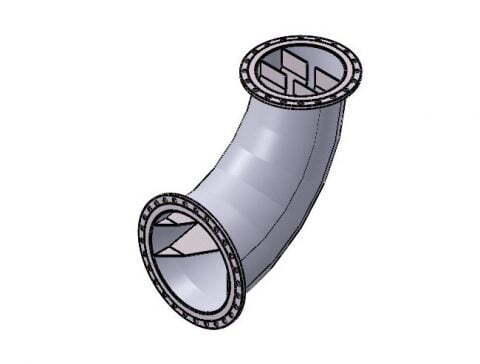

Flow Conditioning Elbow

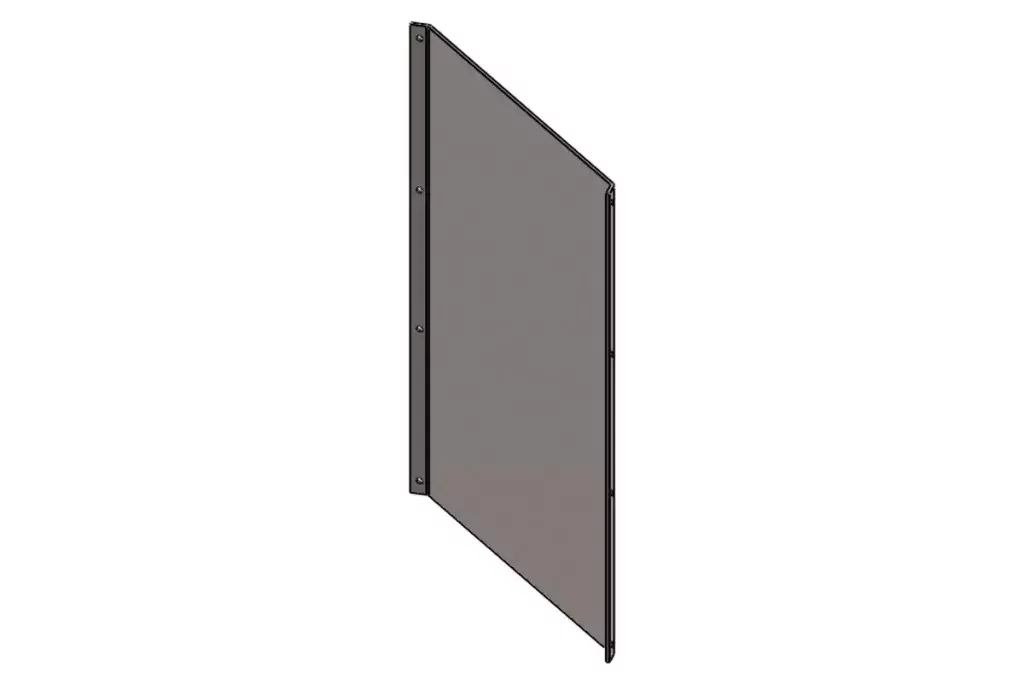

Vaned Eccentric Reducer

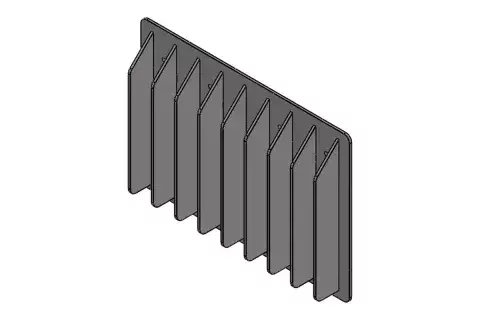

Wall Vane Flow Conditioner

Elevated Corner Fillet

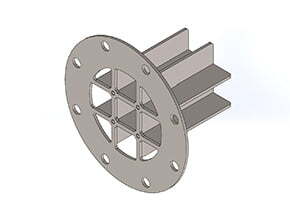

Pump Flow Conditioner

Applications & Solutions

Wastewater

- Smooths flow into influent and effluent pumps

- Reduces turbulence at flow meter locations for accurate readings

- Minimizes wear and energy loss in lift stations and treatment plants

Power Generation

- Conditions pump intake flow for cooling water and boiler feed systems

- Mitigates cavitation and vibration in high-demand applications

Oil & Gas

- Enhances flow profile consistency for custody transfer metering

- Supports stable suction flow in pump skids and separator systems

Food & Beverage

- Improves pump reliability and meter accuracy in CIP and process lines

- Supports NSF-61 compliant stainless-steel components for hygienic use

Chemical & Pharmaceutical

- Ensures stable intake flow for metering pumps and blending processes

- Minimizes pulsation and promotes consistent dosing and flow control

Agriculture & Irrigation

- Reduces turbulence in pump stations for canals and drip systems

- Enhances meter performance for flow-based water management