Precision Flow Measurement & Control Solutions

Clipper Controls provides precision flow measurement and control solutions designed to ensure accuracy, reliability, and performance across a wide range of process conditions. Our technologies support liquid, gas, and steam flow applications in industries such as water and wastewater, power generation, food and beverage, chemical processing, and more. With trusted products from leading manufacturers, we offer flow instrumentation that meets the highest standards for quality, compliance, and long-term dependability.

Gas Flow Measurement

Thermal Mass Flow Meters

Application: Thermal mass flow meters provide direct mass flow measurement for gases. They offer high accuracy and are ideal for low-flow or varying-density applications like HVAC, gas distribution, and biogas.

Ultrasonic Gas Flow Meters

Application: Non-intrusive ultrasonic flow meters use transit-time technology to measure flow in liquids and gases. They provide excellent accuracy, low maintenance, and easy installation. Changing gas composition can be accommodated.

For high-stakes gas metering projects, explore our article about CNG custody transfer tracking & data management systems.

Venturi & Differential Pressure Gas Flow Meters

Vortex Gas Flow Meters

Application: Vortex meters detect flow by measuring vortices shed by a bluff body in the fluid. Suitable for steam, gas, and liquid applications with minimal moving parts and high reliability.

Talk to an Expert

Liquid Flow Measurement (Full Pipe)

Magnetic Flow Meters

Application: Magmeters measure conductive liquids with no moving parts, making them ideal for wastewater, slurries, and corrosive fluids. They deliver long-term reliability and precise performance.

Ultrasonic Liquid Flow Meters

Differential Pressure & Venturi Liquid Flow Meters

Vortex Liquid Flow Meters

Application: Versatile for clean liquid flow, vortex meters are durable, low-maintenance, and unaffected by fluid conductivity or viscosity. Great for water, chemicals, and steam.

Talk to an Expert

Steam Flow Measurement

Ultrasonic Steam Flow Meters

Application: Utilizing ultrasonic signals, these non-intrusive meters accurately measure steam flow without disrupting the process. Ideal for applications requiring minimal pressure drop and high turndown ratios.

Differential Pressure Steam Flow Meters

Vortex Steam Flow Meters

Application: These meters detect vortices shed by a bluff body in the steam flow to determine velocity. They are versatile, handling liquids, gases, and steam, and are commonly used in chemical and petrochemical industries.

Talk to an Expert

Liquid Flow Measurement (Water Flow, Open Channel)

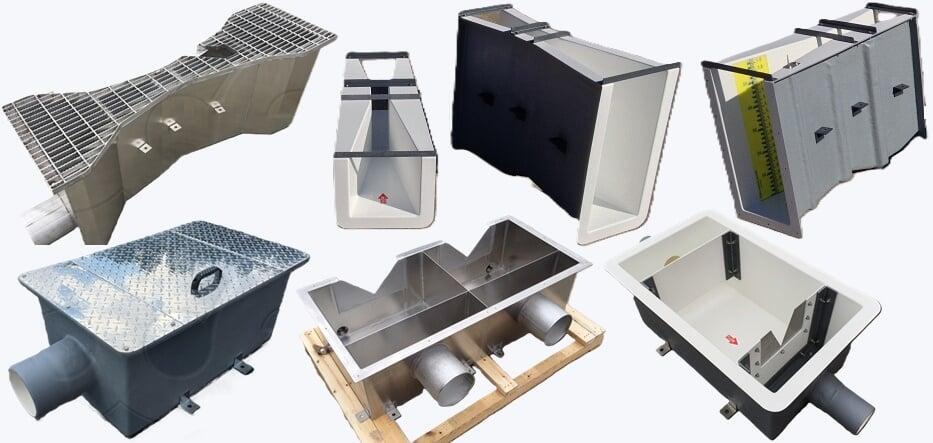

Flumes & Weirs

Application: Flumes and weirs are primary devices used to measure flow in open channels, manholes, and other non-pressurized applications. They are essential in water resource management and irrigation systems.

Flume and Weir Material Comparison

| Material | Corrosion Resistance | Cost | High Temp | Field Repair | Level of Customization | Weight |

|---|---|---|---|---|---|---|

| Aluminum | Good | Above Average | N | Y | Average | Light |

| Galvanized | Low | Low | Y | Y | Average | Heavy |

| HDPE | High | High | N | N | Low | Average |

| Fiberglass (Standard) | Good | Average | N | N | High | Average |

| Fiberglass (Vinyl Ester) | High | High | Y | N | High | Average |

| Stainless Steel | High | High | Y | Y | Average | Heavy |

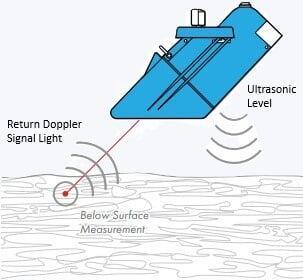

Laser Flow Meters

A non-contact subsurface velocity measuring laser flowmeter ideal for open channel flow applications. It uses advanced laser Doppler technology to measure flow below the surface, making it suitable for challenging conditions like shallow, fast, or debris-laden flows in wastewater, stormwater, and industrial discharge channels.

Submerged Doppler Flow Meters

Manholes

Talk to an Expert

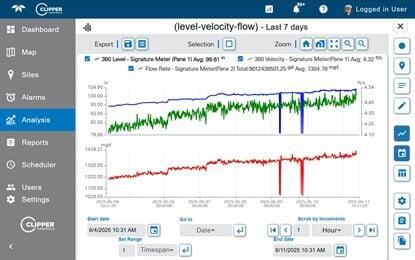

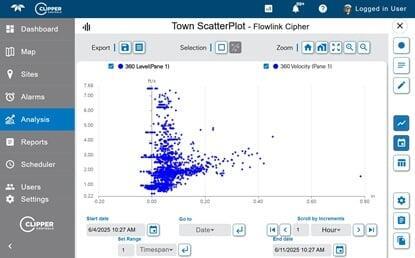

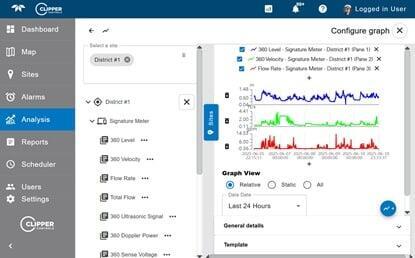

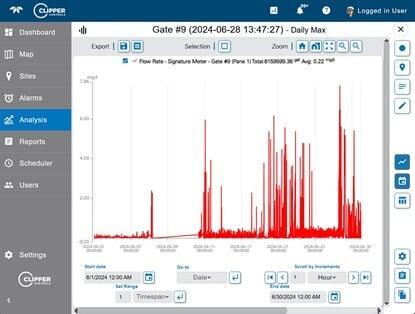

ClipperView Flow Monitoring Software

ClipperView is a cloud-based water data management platform designed for real-time monitoring of effluent flow. Built to integrate seamlessly with ISCO Signature, Duratracker, and a wide range of flow sensors—including LaserFlow, ultrasonic, bubbler, and area velocity meters—ClipperView transforms complex data into actionable insights.

Key Areas of Value:

Real-Time Visibility

Access live flow and level data from any device—no site visits, no manual downloads.Effortless Deployment

No IT infrastructure required. Connect your hardware and start monitoring immediately.Compliance-Ready Alerts

Set custom thresholds and receive instant notifications to prevent overflow and violation risks.Powerful Reporting & Visualization

Overlay rainfall, flow, and site trends to analyze system behavior and support regulatory reporting.Cost-Effective & Scalable

Flexible monthly pricing per site, unlimited users, and no procurement delays.Ideal for:

Talk to an Expert About ClipperView

Flow Switches

Thermal Flow Switches

Application: Thermal dispersion flow switches monitor the flow status of liquids and gases by detecting temperature differences. They are maintenance-free and suitable for applications with contaminated or aggressive media.

Paddle Flow Switches

Talk to an Expert

Need Help?

Our Crew is Here To Serve You!

Flow Measurement & Control Applications

Municipal Water & Wastewater Treatment Applications

Flow measurement and control play a vital role in every stage of municipal water and wastewater treatment—from raw water intake and chemical dosing to effluent discharge and stormwater management. Accurate flow data ensures regulatory compliance, efficient operations, and system optimization.

Recommended Products

Industrial Gas Distribution Applications

Industrial gas distribution requires precise flow measurement and control to manage variable pressures, gas compositions, and flow rates—making reliable instrumentation essential for safety, efficiency, and regulatory compliance.

Recommended Products

Boiler & Steam System Monitoring Applications

Recommended Products

Chemical & Petrochemical Processing Applications

Recommended Products

Food & Beverage Production Applications

Recommended Products

Terms & Definitions

Calibration

The process of adjusting a flow measurement instrument to ensure it provides accurate readings, typically performed against a known standard.

Differential Pressure

The difference in pressure between two points in a system, often used to calculate flow using orifice plates, venturis, or flow nozzles.

Flow Meter

An instrument used to measure the rate or volume of fluid (liquid, gas, or steam) moving through a pipe or open channel.

Flow Switch

A device that detects the presence or absence of flow and triggers alarms, system shutdowns, or automated actions in control systems.

Flow Totalizer

A device that sums the flow over time to provide a cumulative volume or mass, often used for billing, tracking, or reporting purposes.

Flume

A specially shaped structure placed in an open channel to direct flow through a known geometry, enabling accurate flow rate calculation based on fluid level.

Full Pipe Flow

Flow within a completely filled, pressurized pipe—common in industrial and municipal distribution systems.

Mass Flow

A measurement of the actual mass of fluid moving per unit of time, often used for gases or when fluid density changes. Common units include kilograms per hour (kg/h) or pounds per hour (lb/h).

Non-Invasive Flow Meter

A meter that measures flow from outside the pipe, such as clamp-on ultrasonic models, eliminating the need to cut into the piping system.

Open Channel Flow

Fluid flow in a channel that is not completely full, such as a stream, flume, or sewer, where the fluid is exposed to atmospheric pressure.

Transmitter

An electronic device that converts flow sensor data into a standardized signal (e.g., 4–20 mA or digital) for display, logging, or control.

Volumetric Flow

The quantity of fluid passing through a section over time, typically measured in gallons per minute (GPM), cubic feet per second (CFS), or liters per second (L/s).

Weir

A barrier with a precisely shaped opening (notch) that allows water to flow over it. The flow rate is calculated based on the height of water above the notch.

Frequently Asked Questions

What is a flow instrument?

A flow instrument is a device used to measure, monitor, or control the flow rate or volume of a fluid—liquid, gas, or steam—moving through a system. Common flow instruments include flow meters, flow switches, and flow transmitters.

What kind of instruments can measure flow?

What are the types of flow meters?

How do I choose the right flow meter?

Consider the fluid type, flow rate, temperature, pressure, required accuracy, and installation environment when selecting a flow meter. Our team is here and ready to help find the best solution for your application.

What is the difference between volumetric and mass flow measurement?

Volumetric flow measures the volume of fluid passing through, while mass flow measures the actual mass. Mass flow is more accurate when fluid density varies.

How accurate are flow meters?

Accuracy depends on the meter type and application but typically ranges from ±0.1% to ±3% of reading.

What maintenance is required for flow meters?

Regular maintenance may include calibration, cleaning, and inspections. Maintenance frequency depends on the fluid type and meter design.

How does temperature or pressure affect flow measurement?

Temperature and pressure changes can impact fluid density and flow readings. Many meters include compensation features or work with transmitters to adjust readings.

Need Help?

Our Crew is Here To Serve You!

Services We Offer

Instrumentation Calibrations

Rental Equipment

Equipment Troubleshooting

Repairs & Maintenance

Instrumentation

Flow Studies

Startup & Training

Flow Technologies

Flow Monitoring Systems