Flare Gas Meters

👉 Talk to a flare gas measurement specialist to review your flare header conditions, regulatory drivers, and instrumentation options.

What Is a Flare Gas Meter?

A flare gas meter (or flare gas flow meter) measures the flow of gas sent to a flare stack or enclosed combustor. These gases are usually a mix of hydrocarbons, inert gases, and steam from process units, relief valves, and safety systems across the plant.

In normal operation, flare flow is often very low—sometimes near zero—yet still needs to be measured for emissions accounting and leak detection. During upset conditions, those same lines may see extremely high velocities as multiple relief valves open. A good flare gas meter must reliably track both extremes.

In refineries, petrochemical plants, and gas processing facilities, flare gas meters support:

Industrial flare gas monitoring and visibility into what’s going to the flare

Emissions measurement for greenhouse gas and regulatory reporting

EPA 40 CFR Part 60/63 flow monitoring and related compliance needs

Safety assurance, confirming relief and overpressure events are correctly routed

Operational insight, identifying chronic low-level flaring and process inefficiencies

Because of these demands, ultrasonic flare gas measurement has become the preferred approach for serious industrial flare gas monitoring.

A flare gas meter (or flare gas flow meter) measures the flow rate of gas sent to a flare stack or enclosed combustor. That gas is usually a blend of hydrocarbons, inert gases, and steam coming from process units, relief valves, and safety systems across the plant.

Most of the time, flow to the flare is very low—sometimes near zero—but still needs to be monitored for emissions accounting and leak detection. During trips or relief events, those same lines can see extremely high velocities as multiple valves open at once. A good flare gas meter must reliably capture both ends of that range.

In refineries, petrochemical plants, and gas processing facilities, flare gas meters support:

Industrial flare gas monitoring and visibility into what’s going to the flare

Emissions measurement for greenhouse gas and regulatory reporting

EPA 40 CFR Part 60/63 flow monitoring and related compliance work

Safety assurance, confirming relief and overpressure events are handled correctly

Operational insight, helping identify chronic low-level flaring and process issues

Because of these demands, ultrasonic flare gas measurement has become the default choice for many refinery and petrochemical flares, while wet-gas thermal mass is often the better tool for saturated biogas flares.

Why Flare Gas Measurement Is So Challenging

- Very low purge and leak rates in normal operation

- Very high velocities during trips, blowdowns, and upset events

- Turndown ratios that can be in the hundreds or thousands to one

- Continuously changing hydrocarbon mix from different units

- Steam or air assist being added for smokeless operation

- Inert gases and occasional oxygen ingress from leaks or vents

- Chattering relief valves and complex header geometry can create unstable, swirling, or pulsating flow profiles

- Some systems see bidirectional flow in common headers or near tie-ins

- Flare headers are often near atmospheric pressure

- Ideal straight-run piping is rare

- Condensed liquids, slugs, and contamination are routine

Why Ultrasonic Flare Gas Meters Are Preferred

(For refinery / petrochemical / O&G flares)

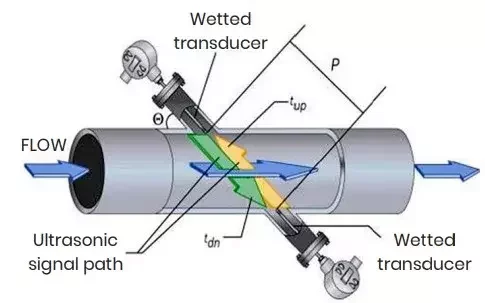

How ultrasonic flare gas measurement works

- There is no additional pressure drop from the meter

- There are no moving parts to wear, foul, or stick

- The same meter can measure very low background flows and high upset flows

Key benefits of ultrasonic flare gas meters

- Non-intrusive measurement – no orifices, restrictions, or turbines in the header

- Very wide turndown – a single system covers background leaks and full-blown relief events

- Handles changing composition – well suited for mixed and variable gas streams

- Works in low-pressure, wet, dirty service – with Panametrics wet-gas compensation improving performance in difficult conditions

- Bidirectional and pulsating flow capability – appropriate for complex, multi-header systems

- Rich diagnostics – signal quality, path availability, and meter health indicators that help you trust the data

Panametrics Flare Gas Meters and Flare Solutions

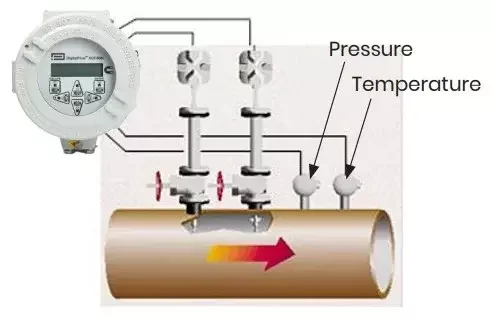

Clipper Controls supplies and supports Panametrics flare gas metering solutions, centered around the DigitalFlow GF868 and DigitalFlow XGF868i ultrasonic flare gas meters and flare optimization tools such as flare.IQ.

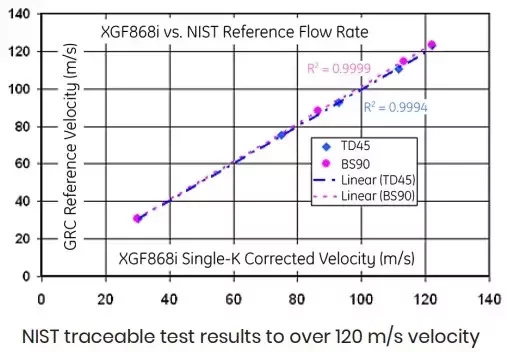

DigitalFlow XGF868i Ultrasonic Flare Gas Flow Meter

- Built for high-turndown, low-pressure flare systems

- Non-intrusive measurement—no extra pressure drop added to the header

- Measures both very low background flows and high upset flows with one meter

- Provides standard volumetric and mass flow outputs for your control system

- Hazardous-area design with options for remote electronics to improve accessibility

DigitalFlow GF868 Ultrasonic Flare Gas Flow Meter

- Measures velocity, volumetric flow, and mass flow of flare gas

- Uses Panametrics Correlation Transit-Time™ technique and advanced digital signal processing

- Supports very wide rangeability (up to 4000:1 turndown) so one system can watch for leaks and capture large trip events

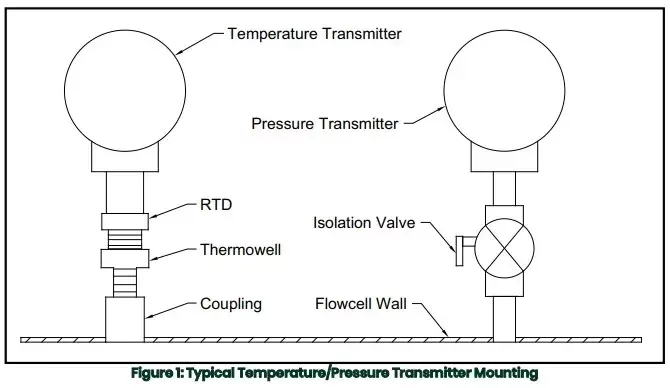

- Can calculate average molecular weight and net heating value (NHV) of vent gas when paired with appropriate inputs

- Engineered to stay on-spec under unsteady, bidirectional, and pulsating flow with changing gas composition and temperature

- GF868 transmitters are typically mounted in analyzer houses or control rooms, with flexible I/O and the ability in some configurations to serve multiple flare lines from a single unit.

Integrating with Panametrics flare.IQ

- Calculate net heating value (NHV) for the flare

- Adjust steam or air assist for smokeless, efficient combustion

- Provide a platform for automated flare control, alarming, and reporting

Transducer options for challenging flare applications

- T5 flare gas transducers – Explosion-proof, all-welded titanium insertion transducers designed for steam and flare gas duties. A strong option for typical flare headers, with multiple head angles and velocity ranges to suit real-world piping.

- T17 high-power transducers – High-output wetted gas transducers engineered for large-diameter pipes and challenging flare applications, with excellent sensitivity at both low and high velocities. Common when you need long acoustic paths and the best low-flow resolution in major refinery or petrochemical flare lines and stacks.

Kurz 454FTB-WGF for Wastewater and Landfill Flare Gas

- Digester gas at wastewater treatment plants

- Landfill gas collection and control systems

- Other saturated biogas applications

- Optimized wet-biogas performance – Designed specifically for saturated, condensing gas where standard thermal mass meters may struggle to stay stable or accurate

- Direct mass flow measurement – Reads biogas mass flow directly, without separate pressure and temperature compensation, simplifying wiring and calculations

- Single-nozzle insertion design – A rugged welded probe that can be installed through one nozzle, ideal for existing flare and biogas piping in brownfield plants

- A good match for smaller lines and moderate velocities – Well suited to the pipe sizes and flow regimes typical of wastewater and landfill gas systems

- Support for reporting and compliance – Provides stable, repeatable biogas mass flow data that can feed into EPA and local air district reporting tools

👉 Ready to compare flare gas technologies or plan a project? Contact Clipper Controls to discuss your flare header, process conditions, and which flare gas meter is the best fit for your site.

Regulatory Drivers: EPA 40 CFR Part 60/63 and Compliance

- Measure and record flare gas flow

- Demonstrate adequate combustion performance and heating value

- Produce defensible data for emissions inventories and reports

Key Features to Look for in a Flare Gas Meter

- Turndown and low-flow sensitivity – Essential for leak detection, background flaring, and high-flow upset events

- Performance with changing composition – Especially important for emissions and mass balance calculations

- Intrusiveness and pressure drop – Non-intrusive or minimal-restriction designs help preserve flare capacity and reduce fouling

- Bidirectional and pulsating flow capability – Real-world flare headers rarely behave like textbook straight runs

- Wet-gas robustness – Ability to handle entrained liquids and mixed-phase conditions, either via ultrasonic wet-gas compensation or wet-gas thermal designs

- Diagnostics and health monitoring – Signal quality, meter status, and alarm outputs that make it easy to see when something isn’t right

- Integration options – Analog and digital outputs that connect cleanly to DCS, SCADA, and flare control systems

Typical Flare Gas Meter Applications

- Refineries – Main and unit flare headers for system monitoring, event reporting, and air permit compliance

- Petrochemical and chemical plants – Relief and vent headers for emissions measurement and MACT/NSPS requirements

- Gas processing, LNG, and midstream – Plant and terminal flares to track lost product and methane emissions

- Tank farms and terminals – Vapor collection headers routed to flares or enclosed combustors

- Offshore platforms and FPSOs – Tight spaces where non-intrusive or transmitter-style ultrasonic meters are preferred

- Wastewater treatment plants and landfills – Wet biogas flares where wet-gas thermal mass meters like the Kurz 454FTB-WGF are typically the better option

How Clipper Controls Supports Flare Gas Projects

Choosing a flare gas meter isn’t just a catalog exercise. Clipper Controls works with you from concept through commissioning to make sure the solution fits your process, flare hardware, and compliance requirements.

Application review

- Line size, pressure, and temperature

- Minimum, maximum, and upset flows

- Gas composition ranges and how they change

- Available straight run and piping constraints

- Applicable environmental and reporting requirements

Solution selection and integration

- Recommending DigitalFlow GF868, DigitalFlow XGF868i, Kurz 454FTB-WGF, and related Panametrics solutions as appropriate

- Selecting the mounting and installation approach: spool piece, insertion transducers, or other approved configurations

- Integrating with DCS/SCADA and, where needed, flare.IQ or other optimization/analytics platforms

Lifecycle support

- Configuration and optimization after startup

- Diagnostic review and troubleshooting when conditions or requirements change

- Expansion to additional flare headers, biogas lines, or units over time

Talk to a Flare Gas Metering Expert

Reliable flare gas flow meters give you:

Clear visibility into flaring activity

Solid data for EPA 40 CFR Part 60/63 and other reporting frameworks

Insight to cut unnecessary flaring and emissions

Confidence that safety and relief systems are doing their job

👉 Ready to improve flare visibility and compliance?

Page Navigation Links

- What Is a Flare Gas Meter?

- Why Flare Gas Measurement Is So Challenging

- Why Ultrasonic Flare Gas Meters Are Preferred

- Panametrics Flare Gas Meters and Flare Solutions

- Regulatory Drivers: EPA 40 CFR Part 60/63 and Compliance

- Key Features to Look for in a Flare Gas Meter

- Typical Flare Gas Meter Applications

- How Clipper Controls Supports Flare Gas Projects

- Talk to a Flare Gas Metering Expert