Capacitive Level Switches

Reliable Point Level Detection for Liquids, Slurries, and Bulk Solids

👉 If you’re already facing nuisance trips or unreliable point level detection, Clipper Controls can help evaluate whether capacitive level switches are the right fit for your silos, bins, tanks, and hoppers. Reach out to us for application assistance or pricing.

Contact us for application assistance!

UWT backs its level instrumentation with a 6-year guarantee, underscoring long-term reliability for capacitive level switch applications.

How Capacitive Level Switches Work – and What Makes UWT Different

Capacitive Point Level Detection Basics

At a fundamental level, capacitive level switches measure a change in capacitance around a probe when material is present versus when it is not. The probe and a reference (often the vessel wall or a built-in reference electrode) form a capacitor, and the process medium—liquid, slurry, or bulk solid—acts as the dielectric between them.

When the probe is in air or gas, the dielectric constant is low and the measured capacitance is relatively small. As product covers the probe, the dielectric constant increases and the capacitance rises. The electronics inside the capacitive point level switch monitor this change; when it crosses a configured threshold, the device changes state and provides a discrete switch output to your control system.

Because this is a solid-state electrical measurement, capacitive point level detection can be applied across a wide range of media:

Liquids with varying conductivity (water-based, oils, chemicals)

Slurries and sludge with entrained solids and changing consistency

Bulk solids such as powders, pellets, grains, and granulates

The underlying physics are the same whether you’re in liquids, slurries, or bulk solids—the difference is how large the capacitance change is for a given material and how the probe design and sensitivity are adapted to that material.

A key implication for users is that changes in dielectric constant (DK) directly affect performance. Switching between products, changing moisture content, or process temperature shifts all change DK. Well-designed capacitive switches allow enough sensitivity margin and a stable electrical reference so they stay reliable even as the product changes over time.

Finally, it’s worth stressing that these devices are point level switches, not continuous level transmitters. They are designed to say “material is here” or “material is not here” at a defined elevation in your silos, bins, tanks, and hoppers for high-level alarms, pump protection, or empty detection—not to provide a continuous level profile.

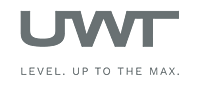

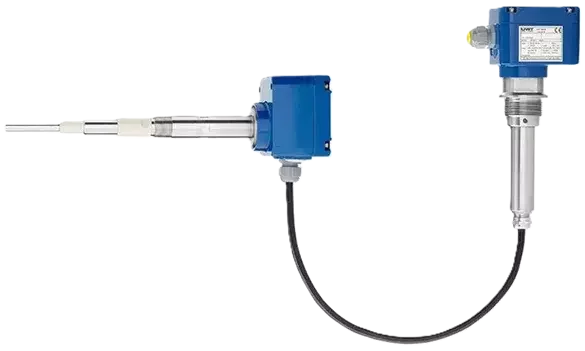

Capanivo CN4020 capacitive level switch showing the classic probe-and-housing design used to measure changes in capacitance when material is present or absent at the switch point.

What Makes UWT’s Capacitive Design Different

On paper, many products are called “capacitive level switches,” but they are not all built the same. UWT’s Capanivo® and RFnivo® families use a combination of RF (radio-frequency) capacitance, integrated electrodes, and Active Shield technology that addresses several common pain points with conventional designs.

Here are the key differences your engineers and technicians actually feel in the field:

RF capacitance: measuring more than just capacitance

Traditional capacitive switches primarily watch a change in capacitance between the probe and vessel wall. UWT’s RF technology uses a high-frequency signal and evaluates both capacitance and impedance (the combined effect of capacitance and resistance). This makes the switching point more stable in dusty, sticky, or low-DK materials where simple capacitive probes can be harder to apply.Integrated reference electrodes – no metallic wall required

Many older capacitance designs depend on a grounded metal vessel wall as the second “plate” of the capacitor. UWT’s Capanivo® sensors integrate both conductive electrodes into the probe itself, so they don’t rely on a bare metal wall and can even be applied on non-metallic or lined vessels when installed correctly. That simplifies grounding and opens up applications on plastic, fiberglass, or rubber-lined tanks.Active Shield technology for buildup and coating

Buildup on a conventional probe often looks like “material present” to the electronics, which can lead to nuisance trips or constant re-tuning. UWT’s Active Shield feature drives a shielding electrode in such a way that deposits, foam, or material accumulating near the process connection have little to no effect on the measurement—the sensor responds primarily to fresh contact at the active tip. That’s a clear advantage in sticky slurries, products that cake, and highly viscous media.Wide DK range and simple calibration

UWT’s RF-based switches are designed to detect materials down to relatively low dielectric constants and many models offer simple or automatic calibration at commissioning—often just powering the unit and performing a quick “empty” / “covered” teach. That helps when you’re dealing with plastics, dry powders, or changing moisture content in bulk solids.Built for extremes: temperature, pressure, and mechanical load

RFnivo® versions are available for high temperatures and high pressures and are mechanically reinforced for abrasive, high-load solids service in large silos or hoppers. Combined with the RF + Active Shield electronics, this gives you a point level device that is both mechanically and electrically robust in the same package.

In practice, these design choices mean that UWT capacitance level switches tend to stay stable where simpler capacitance probes struggle—applications with buildup, coating, variable products, non-metallic vessels, or low-DK bulk solids. Instead of constant re-tuning and cleaning, you get a more forgiving switch that’s easier to standardize across different services.

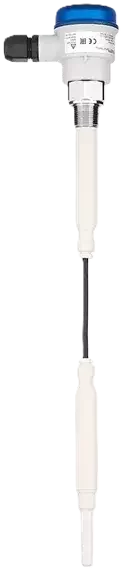

Capanivo CN7121 chemical-resistant capacitive level switch, representing UWT’s integrated electrode design for non-metallic and lined vessels as well as aggressive liquid and slurry applications.

Probe Designs in Practice

Like other capacitive technologies, UWT implements these electronics across several probe geometries so you can match the mechanics to the vessel and process:

Rod probes for short to medium insertion lengths in tanks and hoppers

Cable (rope) probes for deep silos and tall bins where long insertion is needed

Flush and compact probes for chutes, small hoppers, and tight nozzles where mechanical damage is a concern

High-temperature and high-pressure variants for reactors, dryers, kilns, and other demanding services

The difference with UWT is that these mechanical options are paired with the same RF + Active Shield measurement platform, so once your team is comfortable applying one device, that knowledge carries across the rest of the capacitive portfolio—whether Clipper Controls is helping you solve a problem in a sludge tank, a cement silo, or a high-pressure conveying line.

RFnivo RF3200 RF capacitive point level switch, representing UWT’s heavy-duty platform for low-DK bulk solids, high mechanical loading, and demanding silo applications.

Key Application Areas: Silos, Bins, Tanks, and Hoppers

Bulk Solids in Silos and Bins

For many plants, the most demanding applications for capacitive level switches are the bulk storage vessels—silos and bins handling powders, pellets, grains, and granulates. Here, bulk solids capacitive level switches are used primarily for:

High-level alarms to prevent overfills and material spills

Low-level / empty alarms to protect feeders, conveyors, and downstream equipment

Blocked chute or no-flow detection at outlets or transfer points

In these applications, the process engineer isn’t just choosing a technology; they’re fighting physics. Bulk solids create challenges such as:

Dust and fines: airborne material can settle on probes and cause coating or bridging.

Buildup and caking: sticky products or fines can accumulate on the probe surface over time.

Low dielectric materials: plastics, certain powders, and dry organic products may generate a relatively small capacitance change.

Material movement: surging product during filling or discharge can intermittently cover and uncover the probe.

Properly selected and configured point level switches for silos, bins, and hoppers address these issues by combining:

The right probe design (e.g., cable probes for tall silos, abrasion-resistant or coated rods for abrasive or sticky media).

Adjustable sensitivity to reliably detect low dielectric products without tripping on minor coating.

Configurable time delays to ride through short-term contact during filling or dust clouds.

For maintenance and reliability teams, this translates into more dependable capacitive level monitoring in bulk storage applications, fewer nuisance trips when loading trucks or railcars, and better protection against overfill incidents at tall silos where access is limited and downtime is costly.

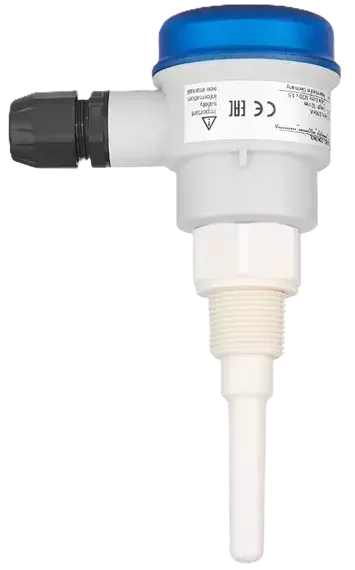

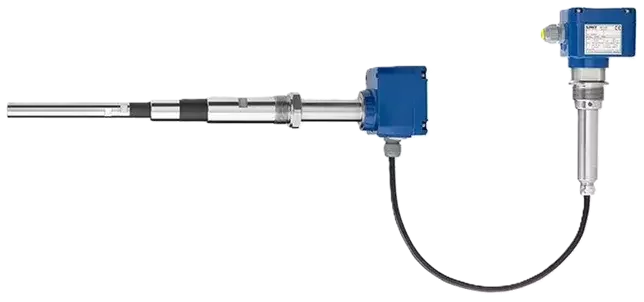

RFnivo RF3100 rope probe capacitive level switch used for high and low level detection in tall silos and bulk solids storage bins.

Liquids and Slurries in Tanks

In tanks and process vessels, industrial capacitive level sensors are widely applied in liquids and slurries for:

High-level alarms to prevent overflow to drains, sumps, or containment

Low-level alarms / pump protection to avoid cavitation, seal damage, or dry running

Interface and presence detection in certain mixed or layered products

Here the challenges are different than in bulk solids, but just as real:

Coating and film formation: viscous liquids, oils, and some chemical products can leave a film on the probe.

Foam and splashing: aerated media, agitation, and infeed nozzles can cause temporary coverage that doesn’t represent true level.

Agitation and mixing: impellers and recirculation lines can create localized turbulence around the probe.

Changing product properties: recipes, temperature, and concentration changes can shift the dielectric constant over time.

Well-applied point level switches for liquids, slurries, and bulk solids leverage the same capacitive principle but rely on:

Coated or insulated probes to minimize the impact of conductive or coating media.

Careful mounting locations, away from agitators and direct inlets, to reduce splash-induced false trips.

Sensitivity and delay settings tuned so that only sustained contact from the actual liquid level causes a switch.

Compared to mechanical float switches, capacitive devices have no moving parts to stick or jam. For maintenance managers, plant engineers, and I&C technicians, this often means lower lifecycle maintenance, improved pump and seal protection, and more reliable interlocks in storage and day tanks, blend tanks, and process vessels.

Capanivo CN7100 compact capacitive level switch provides high-level and pump protection service in process tanks with liquids and slurries.

Chemical-resistant Capanivo CN7121 capacitive level switch designed for aggressive liquids and corrosive tank environments.

Hoppers and Chutes in Harsh Environments

Hoppers, chutes, and transfer points frequently represent the harshest environment for capacitive point level switches. Material is in motion, mechanical loads are higher, and vibration is often continuous. Typical uses include:

Blocked chute detection at conveyor transfers

Low-level or empty detection in small day hoppers feeding mills, reactors, or packaging lines

High-level alarms where back-up or bridging could damage upstream equipment

In these locations, the device must deliver reliable capacitive point level detection while surviving:

Impact and abrasion from fast-moving, often abrasive solids (ores, sand, clinker, pellets).

Vibration and shock from vibrating feeders, crushers, and screens.

Temperature extremes near dryers, kilns, or hot process gas flows.

Space constraints, where mounting is often through small nozzles or on angled walls.

For these reasons, capacitive level switches for harsh environments typically feature:

Rugged mechanical construction with reinforced probes and robust process connections.

Flush or low-profile mounting to minimize direct impact from falling material.

High temperature versions and remote electronics to keep sensitive components away from heat and vibration.

Configurable time delays to avoid false trips from transient slugs of material.

For reliability engineers and controls design teams, the right switch in a hopper or chute is often the difference between stable operation and recurring nuisance alarms, manual interventions, and unplanned downtime at critical transfer points.

RFnivo RF8100 threaded rod capacitive level switch used in rugged hopper and chute applications with impact, abrasion, and vibration.

👉 Get a personalized quote for your level measurement needs — contact Clipper Controls.

If your silos, bins, tanks, or hoppers are experiencing false trips, missed level events, or frequent level switch failures, Clipper Controls can help review your application and recommend capacitive point level switches—including probe styles and mounting options—matched to your specific bulk solids, liquids, and slurry conditions.

Selecting Capacitive Level Switches for Challenging Process Conditions

Process Conditions: Temperature, Pressure, and Chemical Compatibility

The first filter when selecting capacitive level switches for challenging process conditions is the process itself—temperature, pressure, and chemistry. Even the best electronics won’t last if the mechanical design isn’t matched to the environment.

Key checks for your application data sheet:

Temperature range

Minimum and maximum process temperature at the probe.

Transient conditions (CIP/SIP, steam-out, cleaning cycles).

Need for an extended neck or remote electronics to keep the housing cooler.

For high temperature level switch applications, look for probes with ceramic or high-temp insulation and derating curves that match your process.

Pressure and mechanical stress

Maximum operating pressure (including startup/shutdown transients).

Vacuum conditions in certain tanks or reactors.

Mechanical loads from bulk solids (bridging, ratholing, side loads in tall silos).

Ensure the process connection (threaded, flanged) has the correct rating and that the probe is mechanically braced if needed.

Chemical compatibility of wetted materials

Probe sheath material (e.g., stainless steel, Hastelloy, coated metal).

Insulation and coatings (PTFE, PFA, PP, PVDF, ceramics) for corrosive or sticky media.

Seals and gaskets (EPDM, FKM, PTFE) appropriate for the chemical and temperature range.

Getting these basics right prevents premature failures and ensures that industrial capacitive level sensors can perform reliably in reactors, storage tanks, and bulk solids vessels—especially in chemical processing, mining slurries, and wastewater treatment where media can be both aggressive and abrasive.

Capanivo CN8100 explosion-proof capacitive level switch used where high temperature, pressure, and hazardous area approvals are required.

Capanivo CN7150 capacitive level switch with a 65-foot adjustable cable extension providing flexible mounting options in tall silos and deep storage vessels.

Dielectric Properties and Material Behavior

Because capacitive point level switches measure a change in capacitance, the dielectric properties of the product are central to performance.

Practical considerations for dielectric change effects on capacitive level switches:

Dielectric constant (εr) of the media

High dielectric materials (water-based liquids, many slurries) create a strong signal and are easier to detect.

Low dielectric materials (many plastics, grains, dry powders) may require higher sensitivity and careful calibration.

Variable materials and recipes

Multi-product silos (e.g., switching from grain to meal to pellets).

Changing moisture content in bulk solids, which alters the dielectric constant over time.

Blends and batch recipes where composition and temperature shift during the batch.

Sensitivity and margin

Look for UWT capacitive switches with adjustable sensitivity so you can tune the device to your lowest-dielectric product and still maintain margin for buildup and process drift.

Avoid setting sensitivity so high that light coating, condensation, or foam cause nuisance trips.

Make use of time delay settings to distinguish stable level coverage from short-lived contact.

For engineers and I&C technicians, this means that a good capacitive switch isn’t just “go/no-go.” It should give you the flexibility to adapt to changing media and operating conditions without having to swap hardware each time the process changes.

Capanivo CN4020 capacitive level switch, representing how probe design and sensitivity are adapted to different dielectric constants in liquids, slurries, and bulk solids.

Approvals, Safety, and Industry Requirements

In many facilities, approvals and safety requirements are just as critical as performance. The right capacitive point level switch must fit into your safety and compliance framework, not just your vessel.

Key areas to review:

Hazardous area approvals

Dust and gas classified areas in mining, grain handling, chemical processing, and solvent storage.

Confirm that the device carries the required markings for your site (e.g., explosion-protection ratings appropriate to your jurisdiction).

Ensure matching installation practices (intrinsically safe, explosion-proof, increased safety, etc., as required by your standards and design).

Functional safety and overfill protection

Some applications may require devices suitable for use in safety-related systems (overfill protection on tanks, critical pump protection).

Check whether the device has the documentation and diagnostic features needed to support your internal safety requirements.

Industry-specific expectations

Capacitive level switches for mining: dust, vibration, and explosive atmospheres in silos and transfer points.

Capacitive level switches for water/wastewater: corrosive atmospheres, hydrogen sulfide, outdoor installations, and sludge handling.

Capacitive level switches for chemical processing: aggressive media, solvent vapors, and strict hazardous area zoning.

Capacitive level switches for general process industries: utilities, boiler feedwater, cooling systems, and bulk chemical storage.

Capanivo CN4030 capacitive point level switch illustrating the type of UWT devices specified when hazardous area approvals and safety requirements must be met.

Mounting Options and Installation Constraints

Even the best switch will underperform if it’s mounted in the wrong place or with the wrong configuration. For silos, bins, tanks, and hoppers level switches, you’ll want to balance mechanical practicality with good measurement geometry.

Key mounting considerations:

Mounting orientation and location

Top mounting:

Ideal for cable probes in tall silos and deep sumps.

Keep the probe away from inlets to avoid constant impact and splashing.

Side mounting:

Common for high- and low-level points in tanks and bins.

Position slightly above the true desired level to allow for process lag and surges.

Angled or flush mounting:

Useful in hoppers and chutes to minimize mechanical stress and material impact.

Process connection type

Threaded connections (NPT, metric) for standard vessels.

Flanged connections for higher pressure or larger nozzles.

Hygienic or sanitary connections (tri-clamp, aseptic) where cleanability is critical.

Probe length and geometry

Short rods for side-mounted high/low alarms.

Long rods or cables for tall vessels or where the switch must reach far into the vessel.

Flexible cable probes to accommodate tall silos or where installation access is limited.

Installation constraints and retrofit scenarios

Existing nozzles that limit probe diameter or access angle.

Need for remote electronics when access is difficult or the process area is very hot or vibrating.

Space for cable routing, conduit, and junction boxes, especially in congested pipe racks and galleries.

By working through these factors systematically—process conditions, wetted materials, approvals, and mounting constraints—maintenance and engineering teams can narrow down to capacitive point level switches that are genuinely fit-for-purpose, rather than relying on “generic” models that may work on day one but struggle over the long term.

Capanivo CN4050 capacitive level switch with cable extension, highlighting how probe geometry and mounting style are matched to different vessel layouts and installation constraints.

👉 To streamline specification and avoid guesswork, Clipper Controls can review your process conditions, vessel geometry, and compliance requirements, then recommend capacitive level switches—including probe construction, approvals, and mounting options—tailored to your silos, bins, tanks, and hoppers. — contact us today for details and a quote.

Best Practices for Installing and Grounding Capacitive Level Probes

Proper Grounding and Shielding

Because capacitive point level detection depends on small changes in capacitance, electrical reference and noise control matter. Poor grounding is a common root cause of unstable readings and intermittent trips.

Key best practices for installing and grounding capacitive level probes:

Bond the vessel properly

Ensure the tank, silo, or hopper is reliably bonded to plant ground.

For non-metallic vessels, use a grounded reference plate or stilling tube per the manufacturer’s recommendations so the switch has a stable reference.

Ground the switch per the manual

Connect the protective earth (PE) terminal in the housing to plant earth.

Follow any manufacturer-specific notes about internal jumpers or reference connections for plastic or lined vessels.

Use shielded cable where specified

Run shielded cable between the sensor and control panel when recommended, especially in areas with VFDs, large motors, or high switching loads.

Terminate the shield at one end only (typically at the panel or per manufacturer instructions) to avoid ground loops.

Avoid noisy cable routing

Do not run the level switch cable in the same conduit or tray as power feeds to motors, heaters, or VFD outputs.

Cross higher-voltage or high-current cables at right angles where possible.

Check grounding continuity

During commissioning, verify continuity from the probe housing to the plant grounding system.

Confirm resistance is acceptable per your site standards and document the measurement.

Solid grounding and sensible cable practices help the device “see” changes in the process instead of noise in the plant’s electrical environment, improving the stability of industrial capacitive level sensors across liquids, slurries, and bulk solids.

Capanivo CN7120 capacitive level switch housing showing typical arrangement for proper grounding, wiring, and conduit connections.

Close view of the capacitive switch electronics where shielded cable, grounding, and sensitivity adjustments are made during installation.

Mounting Locations to Minimize Buildup and False Trips

Where you put the switch is just as important as how you wire it. Thoughtful mounting can dramatically reduce nuisance trips with capacitive level switches.

Guidelines for silos, bins, tanks, and hoppers level switches:

Stay clear of inlets and fill streams

Avoid mounting directly in the incoming material stream, where splashing or surging bulk solids will repeatedly strike and temporarily cover the probe.

Position the probe so it sees the “true” level, not intermittent splashes or slugs.

Avoid agitators and internal hardware

For tanks, mount away from mixers, baffles, or recirculation lines to reduce turbulence and foaming around the probe.

Check for possible mechanical interference during mixing or CIP/SIP cycles.

Consider flow patterns in bulk solids

In silos and bins, position high-level switches where material builds in normal flow, not in dead zones.

For low-level detection, place the probe where material genuinely disappears in a no-flow condition, not in a region that’s always partially filled.

Use standpipes or stilling tubes when needed

For very turbulent or foaming liquids, a short standpipe or stilling tube can help shield the probe from splashing while still tracking the true level.

Ensure the pipe itself is correctly grounded and that venting prevents false signals from trapped air.

Protect against mechanical damage

In hoppers and chutes, consider flush-mount or recessed probes to minimize direct impact from falling material.

For long cable probes in tall silos, ensure there’s appropriate tensioning or weight so the cable doesn’t whip or snag.

Good mounting practice makes the difference between constant “mystery trips” and a quiet, trustworthy alarm that only activates when level genuinely reaches the set point.

Capanivo CN7130 capacitive level switch with extension tube showing how thoughtful mounting positions help minimize buildup and false trips in real process vessels.

Initial Calibration and Sensitivity Adjustments

Even the most advanced bulk solids capacitive level switches and liquid probes need correct initial setup. Commissioning is the ideal time to calibrate and document your configuration so the device will be robust against real-world variation.

Best practices for initial calibration and sensitivity:

Follow a dry/wet (or empty/full) sequence

Start with the vessel in a known “empty” or “dry” condition at the probe. Record the baseline reading or perform the initial “empty” adjustment if the device supports it.

Then bring the level to a stable “covered” or “wet” condition at the probe and complete the “full” or “product present” adjustment.

Set sensitivity with margin

Adjust the sensitivity so that the “covered” signal is clearly above the switching threshold, but not so close that light coating or condensation triggers the switch.

For low dielectric media, increase sensitivity as needed, but always verify that the probe returns reliably to “not covered” when the level drops.

Apply time delays intelligently

For turbulent or fast-moving processes, add a short on-delay so the probe must be continuously covered for a set time before switching.

Where emptying can be “choppy” (e.g., intermittent discharge), an off-delay can prevent rapid cycling as material falls away from the probe.

Confirm fail-safe behavior and output logic

Select the appropriate fail-safe mode (e.g., safe on loss of power) consistent with your plant standards.

Verify that the control system interprets the switch correctly (e.g., NC vs. NO) and that alarm and interlock logic behaves as intended when you simulate empty and covered conditions.

Document settings and conditions

Record sensitivity, delay parameters, and fail-safe selections in your maintenance system.

Note the product type, dielectric category (low/medium/high), and typical operating temperature when the calibration was performed.

Executing these steps during installation puts you in a strong position for long-term performance and simplifies later work on capacitive level switch calibration and maintenance guidelines and troubleshooting.

👉 For new projects and retrofits, Clipper Controls can support you with best practices for installing and grounding capacitive level probes, including recommended mounting locations, wiring practices, and initial calibration steps tailored to your process conditions and control architecture. — reach out to Clipper Controls.

Calibration, Maintenance, and Troubleshooting

Even a well-selected and correctly installed capacitive level switch needs periodic calibration, maintenance, and troubleshooting to keep performance stable over the life of the asset. A simple, structured approach can greatly reduce downtime and avoid both nuisance alarms and missed level events.

Routine Inspection and Cleaning

Routine checks form the backbone of practical capacitive level switch calibration and maintenance guidelines. Focus on simple, visual inspections backed up by basic functional tests.

Suggested routine tasks:

Visual inspection of probe and housing

Look for buildup, coating, or mechanical damage on the probe—especially in sticky or abrasive media.

Verify that housing covers are secure, cable glands are tight, and no moisture is entering the electronics.

Check wiring and grounding integrity

Confirm that grounding conductors are intact and secure.

Inspect cable insulation for cracking, abrasion, or chemical attack.

Make sure conduit seals and junction boxes remain sealed against dust and moisture.

Functional test where practical

For tanks, simulate level by raising the process level to cover the probe or using approved test functions (e.g., built-in test buttons or test magnets if provided by the manufacturer).

For bulk solids, coordinate with operations to test during filling or emptying when feasible.

Cleaning procedures

Use cleaning methods compatible with the probe materials (avoid tools or solvents that could scratch coatings or degrade seals).

In sticky or coating media, incorporate probe inspection/cleaning into regular shutdowns or wash-down cycles.

Record and trend

Note recurring buildup, fouling, or coating patterns. This information may justify adjusting sensitivity/time delays or switching to a different probe style or coating.

These simple steps help maintain industrial capacitive level sensors in good condition and provide early warning of issues before they become plant incidents.

Capanivo CN7120 compact capacitive level switch with integral mounting features that simplify installation and future service work.

Preventing Nuisance Trips and False Alarms

Preventing nuisance trips with capacitive level switches is usually a combination of good installation, thoughtful setup, and periodic fine-tuning as the process evolves.

Common causes and mitigation strategies:

Buildup and coating

Cause: Deposits on the probe mimic “covered” conditions.

Mitigation:

Use non-stick coatings or insulated probes where appropriate.

Reduce sensitivity slightly if there is excessive margin above the “covered” threshold.

Adjust time delays so brief contact or partial coating doesn’t cause an alarm.

Foam, splashing, and turbulence (liquids/slurries)

Cause: Temporary coverage from foam or splashing near inlets or agitators.

Mitigation:

Relocate the probe away from inlets/agitators.

Install a short stilling tube or standpipe around the probe.

Apply short on-delays so only sustained coverage switches the output.

Dust clouds and surging flow (bulk solids)

Cause: Dust or short-lived surges intermittently cover the probe.

Mitigation:

Use time delays and proper sensitivity settings.

Consider probe designs that are less exposed, such as flush or recessed mounting.

Electrical noise and grounding issues

Cause: Poor grounding or noisy environments near VFDs and large motors.

Mitigation:

Verify grounding, cable shielding, and routing as described in the installation section.

Separate signal cables from high-current and VFD output cables.

By systematically addressing these factors, maintenance and reliability teams can turn a troublesome device into a quiet, dependable capacitive point level switch that only alarms when it should.

RFnivo RF3100 with remote electronics, illustrating how robust probe designs and remote housings help reduce nuisance trips in demanding level applications.

Troubleshooting Missed Level Events

When alarms don’t come in—or don’t come in on time—troubleshooting missed level events in capacitive level applications should follow a structured, step-by-step approach.

Suggested troubleshooting sequence:

Verify power and basic I/O

Confirm the switch has the correct supply voltage.

Check the output wiring (relay contacts, transistor, or solid-state output) for continuity and correct termination in the PLC or control panel.

Look at indicator LEDs or local status displays to see whether the switch is changing state at all.

Check grounding and reference conditions

Ensure the vessel and sensor are properly grounded.

On non-metallic or lined vessels, confirm any required reference electrode or grounding plate is intact and correctly wired.

Review calibration and sensitivity settings

Verify that the device has been taught or calibrated for the correct “empty” and “covered” conditions.

For low dielectric media, confirm sensitivity is high enough to clearly detect the product.

Check that fail-safe mode and output logic haven’t been inadvertently changed, leading to “silent failures” in the control system.

Compare actual process conditions to design

Has the product changed? (different powder, new recipe, higher moisture content, temperature shift)

Have fill or discharge rates changed, affecting how material moves around the probe?

Has any upstream modification (new nozzle, new mixer, changed inlet location) altered the flow pattern?

Inspect for mechanical damage or obstruction

Look for bent rods, slack or broken cables, or probes buried in hardened buildup.

Confirm that the probe is still positioned at the intended level—no mechanical modifications, sagging, or changes in nozzle orientation.

Test the device in controlled conditions

If feasible, remove the switch and test in a controlled environment with a representative sample of the product (or water if testing for basic operation).

If performance remains poor under correct conditions, consider replacement with a more robust model or a different probe style.

When recurring problems persist after this troubleshooting, it may be time to evaluate more advanced or robust designs—such as UWT Level capacitive level switches for harsh environments, which offer adjustable sensitivity, diagnostics, and probe options tailored for difficult media and vessels.

RFnivo RF3300 capacitive limit switch, representing the kind of rugged point level device often selected when troubleshooting missed level events in bulk solids service.

👉 If you’re seeing recurring false alarms or unexplained missed level events, Clipper Controls can help you review your capacitive level switch calibration and maintenance practices, diagnose root causes in the field, and recommend UWT Level solutions better suited to your process and reliability targets. Send us a message.

UWT Capacitive Switch Solutions

UWT Capacitive Point Level Sensor Families

Capanivo® capacitive sensors (CN series)

Compact, fully insulated capacitive point level switches for liquids, slurries, and many bulk solids.

The measuring electrodes are integrated into the probe, so they can be used even when there is no metallic vessel wall available as a reference (ideal for plastic or lined vessels).

Well suited for narrow openings and complex containers where space is limited but you still need reliable point level detection.

Available for both top and side mounting, with short insertion lengths and compact housings that work well on small tanks, hoppers, and OEM skids.

RFnivo® RF capacitance switches (RF series)

Heavy-duty RF capacitive level switches designed primarily for bulk solids and harsh service.

Measure capacitance between the probe and a reference electrode (often the vessel wall), switching when product covers the active probe.

Offer adjustable sensitivity, allowing detection of bulk materials with very low dielectric constants, making them strong candidates for bulk solids capacitive level switches in plastics, powders, and dry granulates.

Rugged mechanical versions rated for high mechanical loading, vibration, overpressure, and elevated temperatures, aligning with demanding industrial duties.

Across these families, UWT incorporates features that map directly to real-world problems:

Active Shield technology to help sensors remain stable even when there is caking and buildup on the probe surface—critical for sticky powders and slurries.

Multiple probe geometries (rigid rods, cable/rope, flush probes) to match silo height, tank geometry, and hopper/chute configurations.

Automatic or simplified calibration, often referenced to an “empty vessel” baseline, so commissioning is quick and repeatable.

For maintenance and engineering teams, that means UWT Level capacitive switches with adjustable sensitivity can be tuned to your lowest-dielectric product while still maintaining stability under coating, dust, and process drift—exactly what you want in tough level service.

Designed for Demanding Industries and Harsh Environments

UWT designs its capacitive portfolio to cover a broad range of industries and process conditions for both solids and liquids. When combined with Clipper Controls’ application support, they map neatly onto the key verticals in your plant:

Mining and minerals

Applications: high- and low-level detection in ore silos, crushed rock bins, transfer hoppers, and blocked chute detection.

Challenges: extreme dust, abrasive solids, vibration, tall vessels, and sometimes elevated temperatures.

Fit: RFnivo® models with high mechanical loading capability, abrasion-resistant probes, and features to mitigate caking are well suited to capacitive level switches for mining where reliability and mechanical robustness are non-negotiable.

Water and wastewater

Applications: sludge hoppers, grit classifiers, hot water tanks, chemical dosing tanks, and pump protection points.

Challenges: hot media, pastes, foams, slurries, and corrosive atmospheres.

Fit: UWT capacitive sensors can be applied in both metal and non-metallic vessels, with reliable operation across conductive and non-conductive media—ideal for capacitive level switches for water/wastewater.

Chemical processing

Applications: reactors, day tanks, solvent and feedstock storage, additive hoppers.

Challenges: aggressive chemicals, vapors, pressure/temperature extremes, plastic- or glass-lined vessels.

Fit: UWT capacitive technology is designed for high temperatures, pressure, and aggressive chemicals, making it a strong choice for capacitive level switches for chemical processing where compatibility and durability are key.

General process industries / utilities

Applications: bulk chemical storage, boiler feed systems, ash handling, raw material silos, OEM skids.

Challenges: mix of bulk solids and liquids, diverse dielectric properties, constrained mounting.

Fit: The combination of compact Capanivo® sensors and heavy-duty RFnivo® probes gives coverage across capacitive level switches for general process industries, from small utility tanks to large raw material silos.

For plants that struggle with caking, coating, or variable products, the UWT Level capacitive switches for harsh environments portfolio offers a practical path to improved reliability without switching technologies every time the process changes.

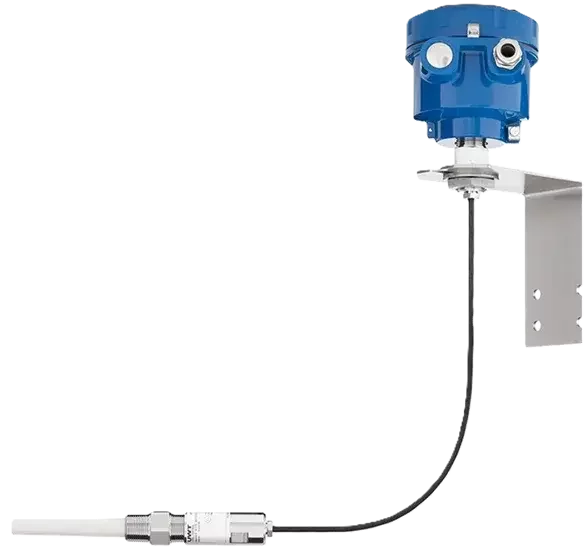

Remote-mount RFnivo RF3200 capacitive level switch keeps electronics away from heat and vibration while the probe monitors solids in the process.

Remote-mount Capanivo CN8100 explosion-proof capacitive level switch, representative of the type of UWT devices Clipper Controls helps specify and integrate into control systems.

Safety, Approvals, and Control System Integration

Beyond mechanical robustness, UWT capacitive switches with safety and industry approvals are designed to live inside real-world compliance frameworks:

Global approvals and certifications

Models are available with the common hazardous area and industry approvals needed in mining, chemical, and process plants.

This allows you to standardize on UWT Level capacitive level switches across sites with differing regional requirements while maintaining a common device family.

Suitable for hazardous dust and gas atmospheres

Capacitive sensors are applied in dust-laden and potentially explosive environments typical of silos, transfer points, and chemical storage.

With the right model and installation concept (selected with Clipper Controls), these switches support your broader safety and environmental protection strategies.

Straightforward integration into control architectures

UWT point level devices provide discrete switching outputs (relay or transistor) that tie directly into standard PLC/DCS digital inputs or hardwired alarm circuits.

They can be wired into:

Pump start/stop and dry-run protection logic

Conveyor and crusher interlocks

Local alarm panels for high/low level indication

Safety relays or shutdown systems where your design requires hardwired interlocks

Diagnostics and “install and forget” philosophy

The product families are designed for long-term durability and low maintenance—essential for remote or difficult-to-access silos and tanks.

For controls design engineers and I&C technicians, this means UWT Level capacitive switches can be treated as standard, robust field devices: simple to power, easy to integrate, and supported with the documentation and approvals needed for project packages and formal MOC workflows.

When supplied and supported by Clipper Controls, these become complete Clipper Controls UWT level switch solutions—matched to your vessels, process conditions, safety requirements, and control system design rather than just picked from a catalog page.

Capanivo CN4030 capacitive level switch, representative of UWT devices that integrate cleanly into PLC, DCS, and safety architectures with the required approvals.

If you’re standardizing on UWT Level capacitive level switches or comparing them to existing point level devices, Clipper Controls can help you choose between Capanivo® and RFnivo® families, select the right probe construction and approvals, and integrate these UWT capacitive point level sensors cleanly into your PLC, DCS, and safety architectures.

👉 Get detailed product specifications: request a datasheet for UWT sensors and transmitters.

Clipper Controls Helps Specify, Apply, and Support Capacitive Level Switches

Application Engineering and Product Selection Support

For most plants, the hardest part of using capacitive level switches isn’t wiring them—it’s making sure you’ve picked the right device, probe style, and configuration for your specific process. That’s where Clipper Controls UWT level switch solutions come in.

Clipper Controls works directly with maintenance, reliability, and I&C teams to translate real-world process data into a clear selection:

Application review

Process conditions: temperature, pressure, chemistry, and cleaning cycles.

Vessel details: geometry, construction material, nozzle locations, and access constraints.

Media properties: bulk density, particle size, abrasiveness, stickiness, and dielectric behavior.

Technology and model recommendation

Guidance on whether a compact Capanivo® or heavy-duty RFnivo® is the better fit.

Recommendation of probe design (rod, cable, flush) and coatings for your silos, bins, tanks, and hoppers.

Matching approvals and mechanical ratings to your plant standards and hazard classifications.

Control-system-aware selection

Ensuring switch outputs align with your PLC/DCS I/O types, safety relays, and alarm panel design.

Aligning fail-safe behavior and contact logic with site-wide control philosophies.

Instead of simply shipping a part number, Clipper Controls helps you design a point level solution that fits the process, the vessel, and the control system as a whole—reducing the risk of nuisance alarms and premature replacements.

Lifecycle Support: Commissioning, Optimization, and Upgrades

The value of a level switch is only realized when it’s in service and behaving reliably. Clipper Controls supports the full lifecycle of capacitive level monitoring in bulk storage applications and process vessels, from startup through optimization and eventual upgrades.

Typical lifecycle support includes:

Commissioning and startup assistance

On-site or remote guidance for mounting, grounding, and wiring practices.

Support for initial calibration and sensitivity settings based on your actual product and operating conditions.

Verification of alarm behavior and interlocks in your PLC/DCS during functional tests.

Optimization and troubleshooting

Helping diagnose nuisance trips or missed level events by reviewing installation, configuration, and process changes.

Fine-tuning sensitivity, time delays, and fail-safe settings to stabilize performance without sacrificing protection.

Recommending probe or model changes when the process evolves beyond the original design envelope.

Planned upgrades and standardization

Replacing aging or problematic legacy level switches with UWT Level capacitive switches for harsh environments where appropriate.

Supporting standardization across sites or units so maintenance teams deal with a smaller, better-understood set of devices.

Coordinating documentation and tag-level changeover so migrations are smooth and traceable.

This lifecycle approach helps maintenance supervisors and reliability engineers turn capacitive switches from “problem points” into background assets that quietly do their job in the plant.

Capanivo CN7130 capacitive level switch, highlighting the type of modern UWT hardware Clipper Controls uses when upgrading and optimizing existing point level installations.

Ensuring Long-Term Compliance and Performance

Point level protection is often tied directly to safety, environmental compliance, and asset protection. Clipper Controls’ role is to align UWT Level capacitive level switches with those broader plant objectives—not just the immediate instrumentation need.

Key areas where Clipper Controls adds value:

Safety and environmental integrity

Helping ensure that overfill protection points, pump protection switches, and blocked chute alarms are designed and applied in line with your site standards.

Matching hazardous area approvals and installation practices to local codes and corporate specifications.

Documentation and traceability

Providing the technical documentation, drawings, and data sheets needed for project packages and Management of Change (MOC) processes.

Supporting consistent naming, tag conventions, and asset records so switches can be easily maintained and audited over time.

Performance over the asset life

Periodic review of performance data to identify troublesome applications and recommend improvements.

Advising when operating changes (different product, new process conditions) warrant recalibration or a change in probe design or model.

By combining robust UWT capacitive point level sensors with local application expertise, Clipper Controls helps plants maintain reliable, compliant, and maintainable point level protection across mining, water/wastewater, chemical, and general process industries.

Compact Capanivo CN7100 capacitive level switch highlighting the high-performance level technology Clipper Controls specifies to support long-term process reliability and compliance.

To get more from your point level strategy, partner with Clipper Controls for UWT Level capacitive switch solutions—from application review and device selection to commissioning, optimization, and long-term support across your critical level applications.

👉 Send us a message or call us at (844) 880-2469

Page Navigation Links

- How Capacitive Level Switches Work – and What Makes UWT Different

- Key Application Areas: Silos, Bins, Tanks, and Hoppers

- Selecting Capacitive Level Switches for Challenging Process Conditions

- Best Practices for Installing and Grounding Capacitive Level Probes

- Calibration, Maintenance, and Troubleshooting

- UWT Level Capacitive Switch Solutions

- Clipper Controls Helps Specify, Apply, and Support Capacitive Level Switches

Click to learn more about UWT Level