Radar Level Transmitters

Reliable Non-Contact Measurement for Liquids and Bulk Solids

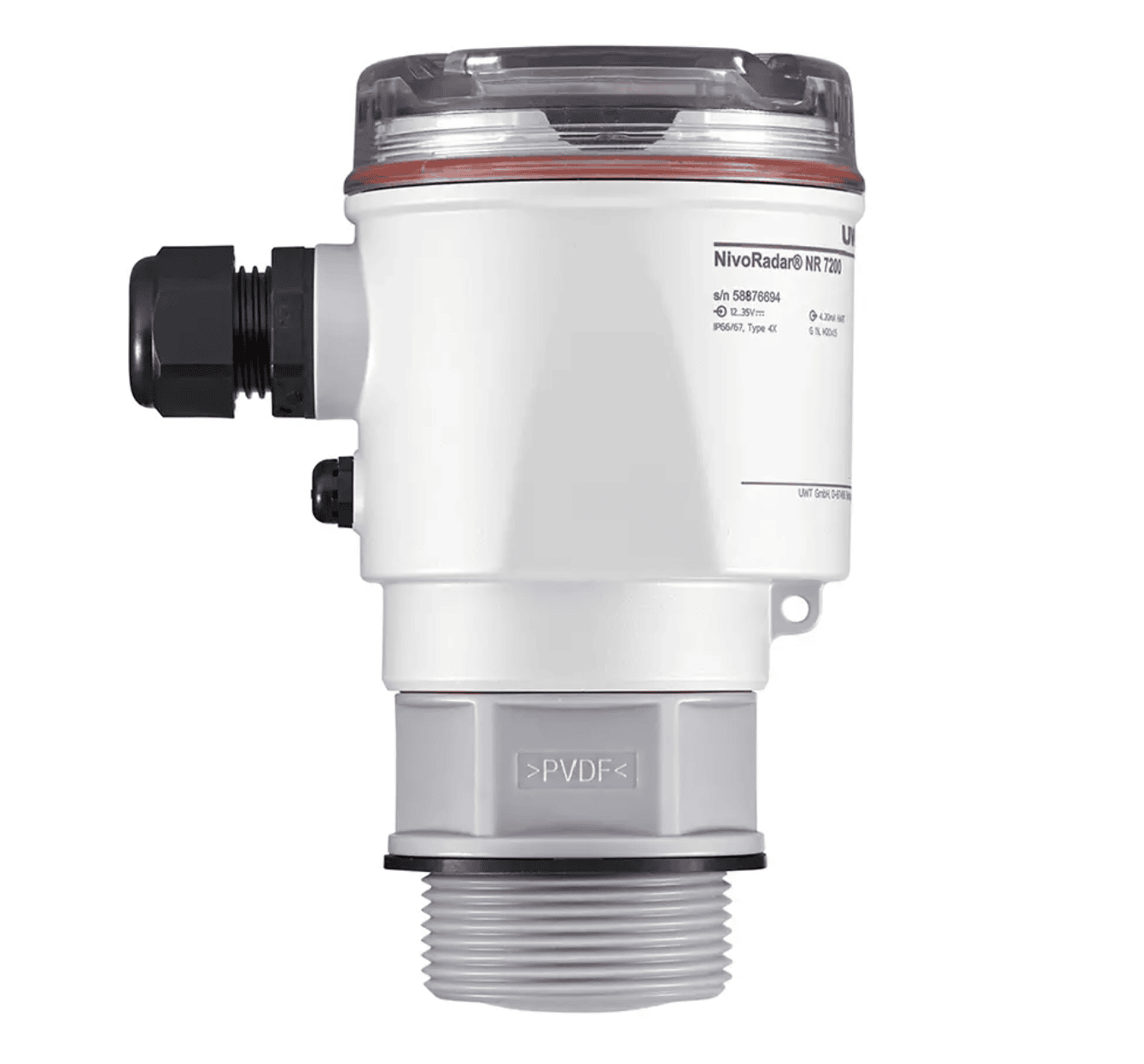

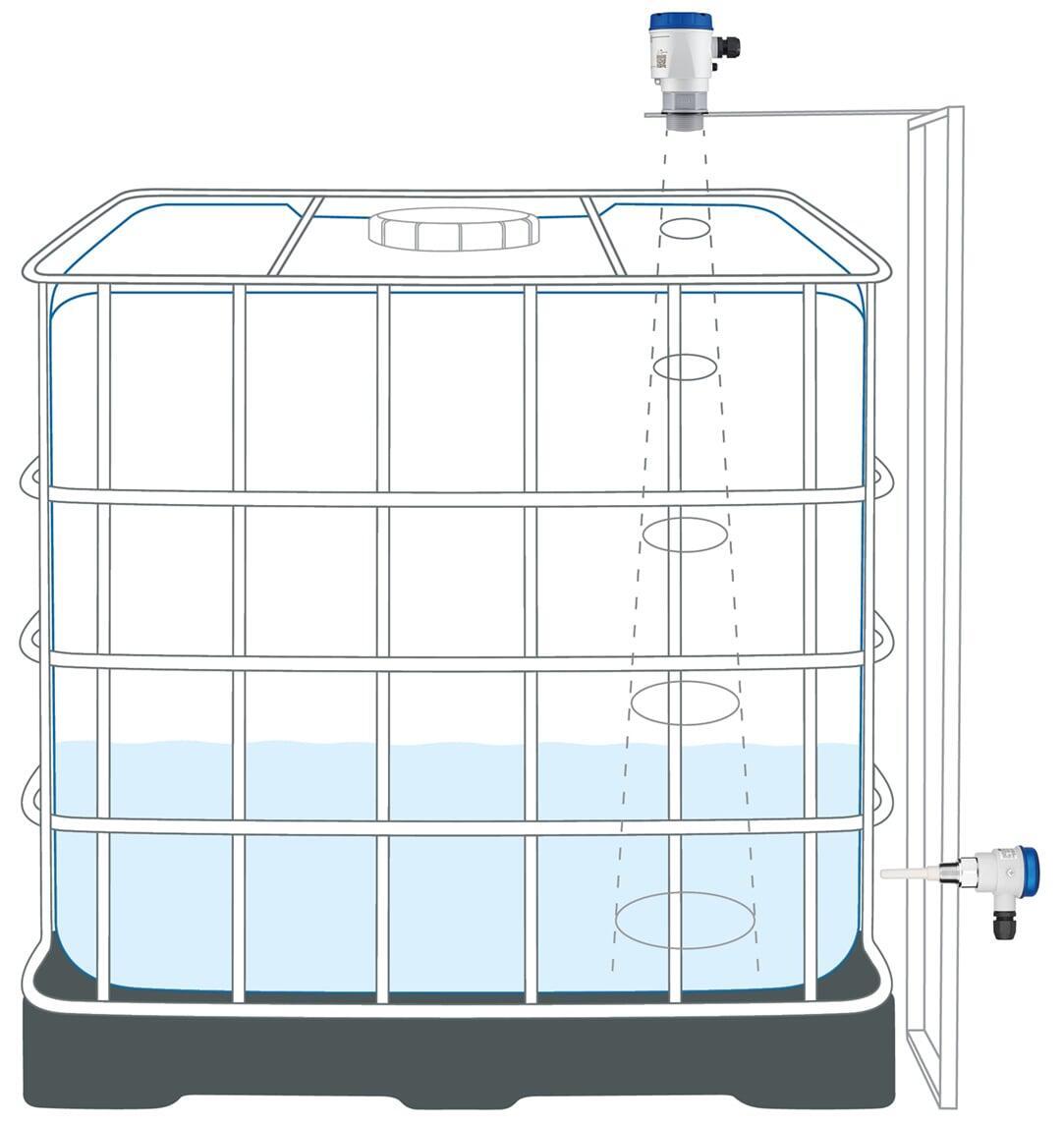

In modern industrial operations, radar level transmitters have become the gold standard for reliable, non-contact measurement of liquids and solids. These instruments work by emitting a microwave radar signal toward the process material and analyzing the time it takes for the signal to reflect back to the sensor. From this data, the device calculates the exact distance to the material surface and delivers a precise level reading.

Unlike ultrasonic or mechanical devices, microwave radar level measurement is not affected by temperature fluctuations, vapor, foam, or dust. This makes radar technology a trusted solution across demanding industries such as water treatment, chemical processing, food and beverage, mining, and bulk material storage. The ability to deliver accurate, repeatable measurements even in harsh conditions helps plants reduce downtime, improve inventory control, and maintain safer operations.

👉 Schedule a consultation with Clipper Controls to explore UWT radar technology.

Why Radar Technology Outperforms Other Level Sensors

- Improved process safety by avoiding unexpected overfills or run-dry conditions.

- Reduced downtime by minimizing sensor maintenance and calibration needs.

- Greater confidence in data accuracy, even in harsh industrial environments.

👉 Get a personalized quote for your level measurement needs — contact Clipper Controls.

Radar Level Transmitters for Bulk Solids

- Stable performance in dusty silos, ensuring reliable readings even during active filling.

- Long-range measurement capabilities, making them suitable for deep storage vessels.

- Advanced signal processing, which adapts to irregular material surfaces and prevents false readings.

- Overfill protection, helping operators avoid costly product losses and safety risks.

👉 Find out which radar level transmitter is right for you — contact us today for details and a quote.

Radar Level Sensors for Liquids and Slurries

- Water and Wastewater Treatment – Monitoring tank levels, clarifiers, and chemical dosing systems with reliable accuracy.

- Chemical Processing – Handling aggressive or hazardous fluids safely without direct sensor contact.

- Food and Beverage Production – Managing ingredients and storage tanks while meeting sanitary and compliance standards.

- Slurry Measurement – Ensuring dependable readings in thick, abrasive mixtures used in mining and industrial processes.

👉 Learn more about how radar level transmitters can improve your operation — reach out to Clipper Controls.

Smart and Connected Radar Level Devices

- Wireless configuration and diagnostics, reducing the need for physical access to difficult or hazardous installation points.

- Mobile app integration, allowing technicians to check readings and adjust settings on-site or remotely.

- Reduced commissioning time, with intuitive setup via smartphone rather than complex programming menus.

- Remote performance optimization, making it easier to fine-tune devices without interrupting plant operations.

👉 Request technical information about radar level transmitters.

Choosing the Right Radar Level Transmitter

- Process material – Liquids, slurries, powders, or grains each present unique measurement challenges.

- Tank or silo geometry – Narrow vessels, angled walls, or very tall silos require advanced radar signal processing.

- Environmental conditions – Dust, vapor, pressure, or extreme temperatures may influence the choice of radar frequency and antenna design.

- Required accuracy – High-precision applications, such as dosing or inventory management, demand the most advanced radar level devices.

👉 Get detailed product specifications: request a datasheet for UWT radar level sensors.

Page Navigation Links

Click to learn more about UWT Level: