Data Center Temperature and Humidity Monitoring Solutions

Contact us for application assistance!

👉 Schedule a free on-site consultation with Clipper Controls to discuss temperature, humidity, and dew point in your data center.

Need service for your sensors or transmitters? Message our Service Team or call us at (844) 880-2469.

Explore related pages: Gas, Flame & Leak Detectors, Calibration Service, Field Services, Analyzers, Equipment Shelters, Process Control Applications

Why precision environmental monitoring matters in data centers

From clean room to data hall: technology built for tight tolerances

- Hyperscale and colocation data halls

- Edge and micro-data centers

- Network rooms, control rooms, and support spaces

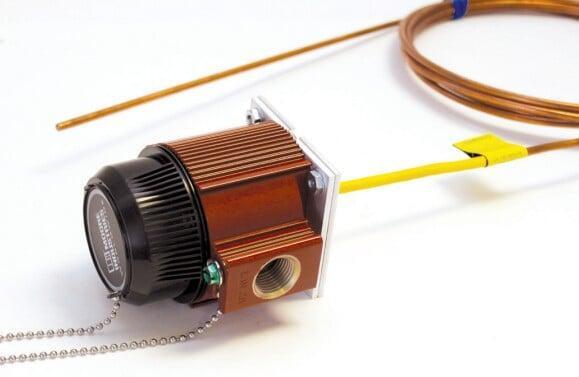

Averaging duct sensors for accurate CRAH and AHU control

- The sensing element runs along a long sheath (typical lengths like 300 or 480 inches), measuring temperature along its full length to deliver a genuine cross-sectional average—ideal across coil faces and large duct sections feeding a data hall.

- System accuracy over common HVAC ranges (for example –20 to 40°C) is tight enough to support precise supply-air control aligned with ASHRAE guidelines.

- A NEMA 4X/IP66 connection head and 4–20 mA loop-powered transmitter withstand mechanical rooms and plenums while making integration with a BMS or PLC straightforward.

👉 Want clean-room–grade accuracy in your AHUs and CRAHs? Talk with Clipper Controls about Moore Industries temperature, humidity, and dew point assemblies that bring that level of precision into your data center.

Duct-mount sensors for branch ducts, cold aisles, and small spaces

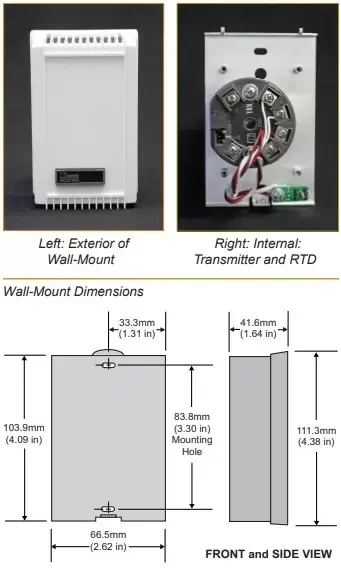

Wall-mount room air temperature monitoring

- Tight system accuracy over common room ranges (for example 10 to 40°C)

- Loop-powered 4–20 mA outputs for simple integration with BMS and DCIM platforms

- A subtle surface-mount enclosure that looks appropriate in finished interiors while still providing industrial-grade performance behind the scenes

👉 Planning cold aisle containment or branch duct upgrades? Call Clipper Controls at (844) 880-2469 and we’ll help you choose duct-mount and point sensors that give complete coverage without overcomplicating the install.

Humidity and dew point monitoring with smart HART® transmitters

- Dual isolated, scalable 4–20 mA outputs that you can assign to RH, temperature, or dew point in whatever combination your control strategy requires.

- Very low system uncertainty with high-accuracy calibration over a wide temperature range, enabling close humidity control.

- Robust housings, stainless-steel probes and thermowells, and industrial-grade components suited for mechanical rooms, coil sections, and mixing boxes.

👉 Curious how RH and dew point control could reduce risk in your white space and mechanical rooms? Contact Clipper Controls to review humidity and dew point transmitter options for your data center.

Calibration strategies for uptime and compliance

Standard factory calibration

High-accuracy bath calibration

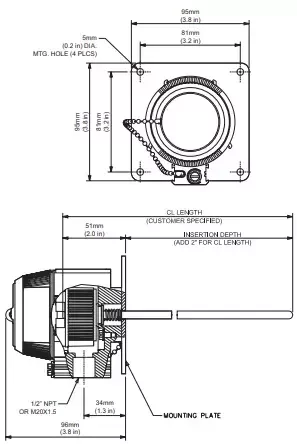

Flexible sensors for process cooling loops and retrofits

- Use a single flexible sensor design that can be trimmed to length to fit multiple thermowell depths and styles, simplifying spares inventory.

- Replace or inspect the sensor quickly during planned outages or service windows.

- Maintain high-accuracy RTD performance on critical process temperatures like chilled-water supply and return.

Ready-to-install assemblies streamline projects

Best practices for deploying temperature and humidity monitoring in data centers

Plan your next data center monitoring upgrade

- High overall system accuracy and long-term stability

- Duct, wall, process, and flexible sensor options for nearly every location

- Factory calibration options with detailed documentation

👉 Ready to plan your next monitoring upgrade? Call Clipper Controls at: (844) 880-2469 or send us a message to discuss a data center environmental monitoring package tailored to your facilities in California, Nevada, and Hawaii.

Work with Clipper Controls

Page Navigation Links

- Why precision environmental monitoring matters in data centers

- From clean room to data hall: technology built for tight tolerances

- Averaging duct sensors for accurate CRAH and AHU control

- Duct-mount sensors for branch ducts, cold aisles, and small spaces

- Humidity and dew point monitoring with smart HART® transmitters

- Calibration strategies for uptime and compliance

- Flexible sensors for process cooling loops and retrofits

- Ready-to-install assemblies streamline projects

- Best practices for deploying temperature and humidity monitoring in data centers

- Plan your next data center monitoring upgrade

- Work with Clipper Controls

Explore more Clipper Controls solutions for data centers and critical facilities, including Industrial Gas, Flame & Leak Detectors, Calibration Service, Field Services, Analyzers, and Equipment Shelters.