Gas & Liquid Analyzers

At Clipper Controls, we specialize in delivering advanced process measurement solutions tailored to the needs of modern industry. Our selection of gas and liquid process analyzers supports critical operations across water treatment, energy production, manufacturing, and environmental compliance. We help customers improve efficiency, ensure safety, and maintain regulatory standards by offering application-specific technologies for accurate detection and continuous monitoring needs. Whether you're analyzing combustion gases, monitoring water quality, or optimizing chemical processes, Clipper Controls provides the instruments and technical guidance to get the job done with precision.

Gas Analyzers

Tunable Diode Laser (TDL) Analyzer

Application: TDL analyzers utilize high-resolution laser spectroscopy to detect specific gas species in process streams, offering fast, non-contact measurements with high selectivity and minimal interference—ideal for hazardous, high-temperature, or corrosive environments.

Chemiluminescent Analyzer

Application: Chemiluminescent analyzers measure nitrogen oxides (NO and NO₂) by detecting the light emitted during their reaction with ozone. These systems offer selectable full-scale measurement ranges from 0–50 ppb up to 0–2,000 ppb for NO, NO₂, NOx, NH₃, and total reactive nitrogen (TNx), making them suitable for both low-level ambient air monitoring and higher-concentration emissions testing. They are widely used for regulatory compliance, environmental monitoring, and combustion process evaluation.

Paramagnetic Oxygen Analyzer

UV Ozone Analyzer

Application: UV ozone analyzers determine ozone concentration by measuring the absorption of ultraviolet light at a specific wavelength. These are critical for ambient air monitoring, ozone disinfection system control, and safety compliance in industrial environments.

Gas Filter Analyzer

Thermal Conductivity Analyzer

Ambient Air Particulate Matter Analyzer

Talk to an Expert

Gas Calibration Equipment

Gas calibration equipment provides precise reference standards used to verify and adjust the accuracy of gas analyzers and sensors. These systems are essential for ensuring reliable measurements in applications such as emissions monitoring, ambient air quality assessments, and industrial process control. Calibration equipment supports traceability to regulatory standards and helps maintain data integrity across continuous monitoring systems.

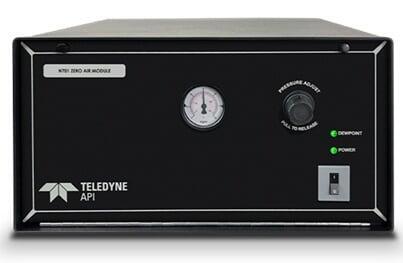

Zero Air Generator

Application: Zero air generators produce high-purity air free of hydrocarbons, moisture, and other contaminants, providing a stable baseline for calibrating gas analyzers. They are used in ambient air monitoring, emissions testing, and laboratory settings to ensure accurate zero-point calibration and improve analyzer sensitivity and repeatability.

Dilution Calibrator

Application: Dilution calibrators create precise gas mixtures by blending a known concentration of calibration gas with zero air, enabling multi-point calibration and linearity checks of gas analyzers. They are used in emissions monitoring, ambient air quality testing, and compliance verification to simulate real-world gas concentrations and ensure accurate analyzer response across the measurement range.

Calibration Gas

Application: Calibration gas is a certified gas mixture used as a reference standard to verify the accuracy and performance of gas analyzers. It is essential for routine calibration, span checks, and regulatory compliance in applications such as emissions monitoring, air quality assessments, and industrial safety. Available in a range of concentrations and gas types, calibration gases ensure measurement traceability and help maintain consistent, reliable data.

Liquid Analyzers

Inline Particle Size Analyzer

Application: Designed for real-time monitoring of particle size distribution in liquid flows, in-line particle size analyzers ensure process consistency in applications such as crystallization, slurry processing, and filtration control.

Optical Dissolved Oxygen Analyzer

Optical Turbidity Sensor

Inline Microwave Percent Total Solids Analyzer

Application: Inline microwave percent total solids analyzers measure the total solids concentration in slurries, pastes, or liquids by evaluating the dielectric properties of the material as it flows through the process. These analyzers provide real-time, non-contact measurement for applications such as sludge dewatering, food processing, pulp and paper production, and chemical manufacturing. By enabling continuous solids monitoring, they help optimize process efficiency, improve product consistency, and reduce energy and chemical usage.

Real-Time BODₑ Sensor

Application: Real-time BODₑ sensors provide continuous measurement of organic load in wastewater by monitoring the oxygen consumption of microorganisms. Using this unique biofilm sensor, we can give an equivalent real-time BOD measurement that reflects the biological demand placed on a treatment system. These sensors are ideal for optimizing aeration control, detecting influent load fluctuations, and ensuring regulatory compliance—offering a faster, more responsive alternative to traditional 5-day BOD tests.

pH Glass Analyzer

Application: pH glass analyzers use glass electrodes to provide accurate pH measurements in a range of aqueous environments, from ultrapure water to high-conductivity solutions. Common applications include chemical dosing control, boiler feedwater monitoring, and laboratory testing.

Conductivity Analyzer

Application: Conductivity analyzers measure ionic content in a liquid to assess purity, concentration, or chemical makeup. Applications include boiler blowdown control, reverse osmosis monitoring, and clean-in-place (CIP) validation in food and pharmaceutical processing.

Fuel and Lube Oil Analyzer

Application: Fuel analyzers use high-resolution imaging and optical sensing to measure the presence and distribution of oil in water or water in oil. These systems are suitable for fuel quality control, contamination detection in separation processes, and real-time monitoring of emulsions in refining, marine, and power generation applications.

Talk to an Expert

Need Help?

Our Crew is Here To Serve You!

Gas & Liquid Analyzer Applications

Semiconductor & Electronics Manufacturing

Ultrapure Water (UPW) Quality Monitoring

Instrumentation Used:

Conductivity analyzers

pH analyzers

Optical and electrochemical analyzers for trace ions or TOC

Application:

Semiconductor fabs require ultrapure water for wafer rinsing and cleaning. Even trace contaminants can damage microscopic features on silicon wafers.

Value:

These analyzers continuously verify the purity of water, ensuring ionic, organic, and pH levels are within ultra-tight tolerances. This prevents yield loss due to contamination and allows for real-time control of polishing, etching, and cleaning processes.

Cleanroom Air Monitoring

Instrumentation Used:

Gas analyzers for VOCs, ammonia, and acids

TDL analyzers for trace gas detection

Particulate monitoring systems

Application:

Cleanrooms must maintain extremely low levels of airborne contaminants to protect wafers during photolithography and deposition processes.

Value:

Gas analyzers identify and quantify airborne molecular contamination (AMC) that could cause wafer defects or corrosion. Continuous air quality monitoring allows proactive maintenance of air handling systems and chemical filtration.

Toxic Gas Leak Detection in Gas Cabinets and Tool Enclosures

Instrumentation Used:

Electrochemical gas analyzers

Infrared or TDL gas analyzers

Thermal conductivity analyzers (for hydrogen)

Application:

Gases such as arsine, phosphine, silane, and hydrogen are used in doping and etching processes. These gases are hazardous and require tight containment and monitoring.

Value:

Real-time leak detection enhances personnel safety and protects expensive process tools. Immediate detection reduces downtime and supports regulatory compliance for toxic gas exposure limits.

Etch and Deposition Process Monitoring

Instrumentation Used:

Gas filter correlation analyzers

Mass balance or thermal conductivity analyzers

Application:

Gas-phase chemistry in plasma etch and CVD (Chemical Vapor Deposition) systems must be tightly controlled for repeatable layer formation.

Value:

Analyzers validate gas composition, detect process drifts, and ensure recipe adherence. This increases wafer uniformity, reduces rework, and shortens development cycles for new process nodes.

Wastewater Discharge and Reclaim Water Quality Control

Instrumentation Used:

BOD sensors

pH and conductivity analyzers

Optical particle size analyzers

Microwave analyzers for chemical concentration

Application:

Semiconductor fabs generate wastewater with metals, solvents, and acids that must be treated before discharge or reuse.

Value:

Liquid analyzers monitor treatment efficiency and ensure effluent meets environmental regulations. They also support water recycling programs by verifying treated water quality for non-critical reuse, reducing water consumption and discharge costs.

Chemical Blending and Dispense Systems

Instrumentation Used:

Microwave analyzers

Conductivity and pH analyzers

Optical and electrochemical concentration analyzers

Application:

Precision chemical dilution and blending is required for CMP slurries, etchants, and cleaning solutions used in wafer fabrication.

Value:

Inline analyzers ensure accurate chemical concentration, minimizing variability and waste. This improves process consistency and reduces the frequency of tank analysis or manual sampling.

Power Generation Applications

Stack Emissions Monitoring

Instrumentation Used:

Chemiluminescent gas analyzers (NOx)

Gas filter correlation analyzers (CO, CO₂)

Paramagnetic oxygen analyzers

Application:

Monitoring flue gas composition at the stack to comply with environmental emissions regulations.

Value:

Ensures regulatory compliance with air quality standards (e.g., EPA, CARB) and enables real-time combustion control. Accurate emissions data supports permitting, reporting, and optimization of air pollution control equipment such as SCR and FGD systems.

Combustion Optimization in Boilers and Turbines

Instrumentation Used:

TDL analyzers (O₂, CO, CH₄)

Paramagnetic oxygen analyzers

Thermal conductivity analyzers

Application:

Monitoring excess oxygen and flue gas composition in fossil fuel and biomass-fired boilers, gas turbines, and combined cycle plants.

Value:

Improves combustion efficiency, reduces fuel consumption, and minimizes emissions. Enables fine-tuning of burner performance to prevent incomplete combustion, slagging, and fouling.

Hydrogen Purity Monitoring

Instrumentation Used:

Thermal conductivity analyzers

TDL analyzers

Inline Moisture analyzers (for H₂ dew point)

Application:

Monitoring hydrogen purity in cooling systems for large generators or in hydrogen production and storage for clean energy applications.

Value:

Ensures gas purity for generator cooling efficiency and safety, or for maintaining quality in hydrogen fuel streams. Contaminant detection prevents electrical arcing, corrosion, and premature component failure.

Cooling Water Chemistry and Cycle Chemistry Control

Instrumentation Used:

Conductivity analyzers (cation, degassed, and specific conductivity)

pH analyzers

Silica and sodium analyzers

Microwave and optical analyzers (chemical concentration)

Application:

Continuous monitoring of boiler feedwater, condensate, and cooling tower systems.

Value:

Prevents corrosion, scaling, and carryover in high-pressure steam systems. Supports chemistry programs (e.g., AVT, phosphate, all-volatile treatment) and maximizes asset longevity while avoiding unplanned downtime.

Turbine Inlet Air Quality Monitoring

Instrumentation Used:

Gas analyzers (ammonia, ozone, VOCs)

Particulate analyzers

Humidity sensors

Application:

Monitoring air quality at gas turbine inlets to protect compressor blades and combustion dynamics.

Value:

Reduces risk of fouling, corrosion, and flame instability. Improves turbine performance and extends maintenance intervals.

Biogas and Landfill Gas Monitoring (Renewable Energy)

Instrumentation Used:

Thermal conductivity analyzers (CH₄/CO₂ ratio)

TDL analyzers (moisture, H₂S)

Electrochemical gas analyzers

Application:

Measuring gas composition in biogas engines or anaerobic digester systems to optimize engine combustion and gas upgrading.

Value:

Improves biogas energy yield and engine protection, while ensuring compliance with pipeline injection standards or flare regulations. Enables safe handling of corrosive gases like H₂S.

Municipal Water & Wastewater Applications

Influent and Effluent Water Quality Monitoring

Instrumentation Used:

pH analyzers

Conductivity analyzers

BOD/COD sensors

Turbidity and TSS analyzers

Optical UV analyzers (for organics and nitrates)

Application:

Continuous monitoring of water entering and exiting treatment facilities to track pollutant load and verify compliance with discharge permits.

Value:

Ensures that influent characteristics are suitable for process design and that effluent meets regulatory standards. Early detection of load spikes allows proactive treatment adjustments, while real-time monitoring supports accurate reporting and permits optimization of chemical usage.

Aeration Basin and Biological Process Control

Instrumentation Used:

Dissolved oxygen (DO) analyzers

Ammonium, nitrate, and phosphate analyzers

pH and temperature sensors

Application:

Controlling oxygen supply and nutrient levels in activated sludge, MBR, and other biological treatment systems.

Value:

Maintains optimal microbial activity, reduces energy consumption from over-aeration, and ensures complete nutrient removal. Supports nitrification/denitrification processes critical to reducing ammonia and total nitrogen in effluent.

Sludge Dewatering and Thickening Optimization

Instrumentation Used:

Inline particle size analyzers

TSS and turbidity analyzers

pH analyzers

Application:

Monitoring solids concentration in sludge to improve thickening and dewatering efficiency.

Value:

Improves polymer dosing control, reduces sludge disposal costs, and enhances performance of centrifuges or belt filter presses. Stable solids handling improves downstream equipment life and reliability.

Chemical Dosing and Disinfection Control

Instrumentation Used:

pH and ORP analyzers

Chlorine (free and total), ozone, and UV analyzers

Microwave or electrochemical analyzers for chemical concentration

Application:

Automated monitoring and control of chemicals for pH adjustment, coagulation, oxidation, and final disinfection.

Value:

Maintains proper residual disinfectant levels for pathogen control, minimizes chemical overuse, and prevents corrosion or formation of disinfection byproducts. Enables precision dosing for regulatory compliance and process efficiency.

Gas Monitoring in Digesters, Headworks, and Chemical Storage Areas

Instrumentation Used:

Methane, hydrogen sulfide (H₂S), ammonia, and VOC gas analyzers

TDL or electrochemical gas sensors

Oxygen deficiency monitors in confined spaces

Application:

Detecting toxic or combustible gases in anaerobic digesters, grit chambers, or storage areas where hazardous gases may accumulate.

Value:

Protects worker safety and facility infrastructure by enabling early leak detection or overpressure conditions. Supports biogas capture efficiency and flare system compliance.

Membrane Integrity and Desalination Process Monitoring

Instrumentation Used:

Conductivity analyzers

Silica and sodium analyzers

Optical turbidity analyzers

Application:

Monitoring membrane performance in reverse osmosis (RO) and ultrafiltration systems for desalination and potable water production.

Value:

Identifies membrane fouling, scaling, or breach events before they impact water quality. Conductivity monitoring across stages ensures proper salt rejection, protecting product water quality and optimizing membrane lifespan.

Corrosion Control and Distribution System Monitoring

Instrumentation Used:

pH and ORP analyzers

Chlorine residual analyzers

Conductivity analyzers

Application:

Monitoring treated water chemistry in storage tanks and distribution networks to minimize pipe corrosion and maintain disinfection residuals.

Value:

Prevents lead and copper leaching in distribution systems and ensures customer tap water meets regulatory safety standards. Stabilizing water chemistry also reduces maintenance and pipe failure.

Environmental Compliance and Reporting

Instrumentation Used:

BOD/COD analyzers

Ammonia, phosphorus, and nitrate analyzers

Gas-phase analyzers for odor control (e.g., H₂S, VOCs)

Application:

Continuous environmental monitoring for effluent discharge, air quality, and nutrient loads in sensitive watershed areas.

Value:

Enables data-driven compliance reporting, protects local ecosystems, and reduces risk of fines or violations. Supports sustainability initiatives and transparency with regulators and the public.

Pharmaceuticals & Biotech Applications

Fermentation and Bioreactor Monitoring

Instrumentation Used:

Dissolved oxygen (DO) analyzers

pH analyzers (glass or ISFET)

Optical and electrochemical analyzers for CO₂ and nutrient levels

Application:

Monitoring and controlling the biochemical environment inside fermenters and bioreactors for cell culture, enzyme production, and microbial synthesis.

Value:

Maintains optimal growth conditions to maximize yield and product consistency. Enables precise control of gas flow rates, nutrient dosing, and metabolic byproduct removal, supporting GMP and PAT (Process Analytical Technology) compliance.

Water for Injection (WFI), Clean-in-Place (CIP), and Sterilization-in-Place (SIP) Systems

Instrumentation Used:

Conductivity analyzers

pH analyzers

TOC (Total Organic Carbon) analyzers

Application:

Monitoring water purity and verifying cleaning cycle effectiveness in WFI systems and CIP/SIP operations.

Value:

Ensures cleaning processes meet regulatory standards (e.g., USP <643>, <645>, <645>) without leaving behind contaminants that could compromise sterile production. Reduces downtime by allowing real-time validation of cleaning efficacy and water quality.

Environmental Monitoring in Cleanrooms and Aseptic Areas

Instrumentation Used:

Gas analyzers for VOCs, ammonia, and oxidizing agents

Particulate and microbial monitoring systems

Humidity and temperature sensors

Application:

Continuous monitoring of air quality in manufacturing suites, isolators, and fill/finish lines.

Value:

Protects sterile environments from microbial contamination and chemical intrusion. Enables rapid response to contamination events and supports documentation for FDA and EU Annex 1 compliance.

Off-Gas Analysis in Upstream Bioprocessing

Instrumentation Used:

TDL gas analyzers (O₂, CO₂, CH₄)

Infrared or mass-based gas analyzers

Application:

Measuring gas composition in exhaust streams from fermenters or bioreactors.

Value:

Provides real-time insight into cell respiration and metabolic activity. Enables non-invasive monitoring that enhances batch control, improves reproducibility, and supports scale-up strategies.

Buffer and Media Preparation

Instrumentation Used:

Conductivity analyzers

pH analyzers

Optical or microwave concentration analyzers

Application:

Controlling the quality and consistency of buffer solutions and media used in upstream and downstream processing.

Value:

Ensures batch-to-batch consistency of critical process fluids, reducing variability and supporting process validation. Accurate pH and ionic strength are critical to protein folding, binding, and separation performance.

Gas Supply and Safety Monitoring

Instrumentation Used:

Oxygen deficiency monitors

Hydrogen and solvent vapor analyzers

Thermal conductivity or electrochemical gas detectors

Application:

Monitoring bulk gas supply systems (e.g., nitrogen, oxygen, CO₂) and lab-scale solvent storage for safety and quality control.

Value:

Ensures safety in confined spaces and production zones by detecting leaks and oxygen depletion. Also protects gas supply integrity for critical process steps requiring high-purity gases.

Waste Stream and Effluent Monitoring

Instrumentation Used:

BOD/COD analyzers

pH and conductivity analyzers

Optical analyzers for solvents and active pharmaceutical ingredients (APIs)

Application:

Monitoring chemical and biological waste streams from production and cleaning processes.

Value:

Supports environmental compliance and waste minimization. Early detection of solvent breakthrough or high organic loads allows for corrective action before violations occur.

Final Product Quality Assurance

Instrumentation Used:

pH and conductivity analyzers

Optical analyzers (e.g., UV-VIS, IR) for concentration verification

Particle size analyzers for suspension or emulsion products

Application:

Verifying that final formulations meet specifications before packaging and release.

Value:

Enables in-process quality checks that reduce rework and batch rejection. Enhances traceability and supports regulatory documentation for product release under cGMP.

Food & Beverage Applications

Process Water Quality Monitoring

Instrumentation Used:

pH analyzers

Conductivity analyzers

Turbidity sensors

TOC (Total Organic Carbon) analyzers

Application:

Monitoring the quality of incoming and process water used in cleaning, cooking, mixing, and ingredient preparation.

Value:

Ensures that water meets food-grade quality standards. Prevents contamination that could affect product taste, safety, or microbial stability. Reduces risk of product recalls and improves compliance with regulatory standards like FDA and HACCP.

Clean-in-Place (CIP) and Sanitation Validation

Instrumentation Used:

Conductivity analyzers

pH analyzers

Chemical concentration sensors (optical or microwave)

Temperature sensors (often integrated)

Application:

Real-time monitoring of CIP cycles to validate that cleaning agents are properly dosed and rinsed from production equipment.

Value:

Reduces downtime between batches, ensures complete cleaning without chemical residue, and avoids microbial contamination. Supports automated cleaning protocols and documentation for audit readiness.

Fermentation Process Control (Breweries, Vinegar, Yogurt, etc.)

Instrumentation Used:

Dissolved oxygen (DO) analyzers

pH analyzers

CO₂ and ethanol gas analyzers

Temperature and turbidity sensors

Application:

Controlling fermentation environments in the production of beer, dairy, kombucha, and other cultured foods.

Value:

Optimizes flavor development, alcohol content, and consistency. Enables real-time adjustments to temperature, oxygen supply, or ingredient feed, improving batch yield and reducing waste.

Packaging Atmosphere Verification (MAP & Beverage Bottling)

Instrumentation Used:

Gas analyzers for O₂, CO₂, and N₂

TDL or electrochemical gas sensors

Application:

Monitoring the gas composition inside Modified Atmosphere Packaging (MAP) or beverage containers to ensure shelf-life and product safety.

Value:

Verifies that the correct gas mix is present to inhibit spoilage and oxidation. Protects product freshness in meats, dairy, baked goods, and carbonated drinks. Reduces packaging rework and improves brand reputation.

Syrup, Sauce, and Dairy Concentration Control

Instrumentation Used:

Microwave or refractometric concentration analyzers

Conductivity analyzers

Inline particle size analyzers

Application:

Measuring sugar, salt, or solids concentration in high-viscosity products like sauces, syrups, and dairy concentrates.

Value:

Ensures consistent flavor and viscosity across batches. Reduces overuse of costly ingredients and supports automated blending systems. Improves yield and reduces off-spec production.

Environmental Discharge and Wastewater Monitoring

Instrumentation Used:

BOD and COD analyzers

pH and turbidity analyzers

Conductivity analyzers

Nutrient analyzers (ammonia, phosphate)

Application:

Monitoring wastewater and discharge streams for compliance with local environmental regulations.

Value:

Reduces risk of fines and environmental damage. Optimizes wastewater treatment systems and supports sustainability goals by identifying opportunities for water reuse and nutrient recovery.

Gas Leak Detection in Refrigeration and Storage Areas

Instrumentation Used:

Ammonia gas detectors

CO₂ gas analyzers

Oxygen deficiency monitors (in CO₂-enriched storage)

Application:

Detecting leaks in refrigerated storage, ripening chambers, or CO₂-injected cold rooms.

Value:

Protects worker safety and prevents costly product loss due to spoilage. Ensures compliance with occupational health regulations and helps maintain safe ambient conditions in controlled environments.

Inline Quality Control in Mixing and Blending Lines

Instrumentation Used:

Optical analyzers (UV/VIS or NIR)

pH and conductivity sensors

Density or refractive index sensors

Application:

Verifying composition of blended products such as juices, soft drinks, and flavorings during processing.

Value:

Improves batch uniformity and reduces need for manual sampling or lab analysis. Supports closed-loop automation for real-time correction and less product waste.

Mining and Mineral Processing Applications

Ore Slurry Monitoring and Concentration Control

Instrumentation Used:

Inline particle size analyzers

Microwave concentration analyzers

Turbidity and solids analyzers

Application:

Monitoring the particle size distribution and solids concentration in ore slurries during grinding, flotation, or thickening processes.

Value:

Improves recovery rates and energy efficiency by optimizing grind size and reagent use. Ensures consistent feed to flotation cells or leach tanks, reducing chemical consumption and maximizing metal yield.

pH and Redox Control in Leaching and Flotation

Instrumentation Used:

pH analyzers (glass or ISFET)

ORP (oxidation-reduction potential) analyzers

Conductivity analyzers

Application:

Controlling acidity and oxidation potential in hydrometallurgical circuits such as cyanide leaching, acid leach, and sulfide flotation.

Value:

Maintains chemical conditions for optimal metal solubilization or mineral separation. Prevents reagent waste and enhances safety, particularly in cyanide handling and recovery.

Tailings and Wastewater Monitoring

Instrumentation Used:

Turbidity and TSS analyzers

pH and conductivity analyzers

Heavy metal analyzers (optical or electrochemical)

Application:

Monitoring tailings ponds and mine effluent to manage environmental discharge and support water recycling.

Value:

Ensures compliance with environmental regulations related to suspended solids, pH, and metal concentrations. Early detection of leaks or treatment system failures helps prevent fines and environmental damage.

Acid Mine Drainage Detection and Control

Instrumentation Used:

pH analyzers

Conductivity and sulfate analyzers

ORP sensors

Application:

Monitoring runoff from sulfide ore sites where exposure to air and water generates acidic drainage.

Value:

Supports mitigation efforts by enabling timely neutralization or containment. Protects nearby water bodies and ecosystems from long-term contamination and supports reclamation strategies.

Reagent Dosing Control

Instrumentation Used:

Microwave or optical concentration analyzers

pH and conductivity analyzers

Flow sensors (often integrated with analyzers)

Application:

Real-time monitoring of reagents such as lime, flocculants, collectors, and frothers in flotation or thickening processes.

Value:

Improves dosing accuracy to reduce costs and improve separation performance. Avoids overdosing that leads to excessive chemical use or underdosing that reduces product recovery.

Gas Detection in Underground and Surface Mines

Instrumentation Used:

Gas analyzers for methane (CH₄), hydrogen sulfide (H₂S), and carbon monoxide (CO)

Oxygen deficiency monitors

TDL or electrochemical gas detectors

Application:

Continuous monitoring of ventilation air and confined spaces in underground mining operations or during blasting.

Value:

Protects worker safety by detecting explosive or toxic gases before dangerous concentrations are reached. Ensures compliance with mine safety regulations and reduces risk of fire, explosion, or asphyxiation.

Boiler and Power Plant Water Quality in On-Site Generation

Instrumentation Used:

pH and conductivity analyzers

Silica and sodium analyzers

Dissolved oxygen analyzers

Application:

Monitoring boiler feedwater and condensate in on-site power plants used in remote mining locations.

Value:

Prevents corrosion, scaling, and carryover in steam systems, ensuring reliable operation of power generation assets. Supports continuous plant operation and reduces downtime in off-grid mining camps.

Air Quality and Dust Monitoring at Crushing and Conveying Areas

Instrumentation Used:

Particulate matter analyzers (PM10, PM2.5)

Gas analyzers for NOx, SO₂, and VOCs

Humidity and temperature sensors (often paired)

Application:

Monitoring fugitive dust and air emissions in processing plants, stockpiles, and transfer points.

Value:

Supports compliance with air quality regulations and protects workers from respiratory hazards. Enables targeted use of dust suppression systems, improving working conditions and environmental performance.

Terms & Definitions

- Acid Mine Drainage (AMD)

- Acidic water generated from the oxidation of sulfide minerals, often requiring neutralization before environmental discharge.

- Air Quality Monitoring

- The continuous assessment of airborne contaminants to ensure compliance with health, safety, or cleanroom standards.

- Biological Treatment

- A wastewater process that uses microorganisms to break down organic pollutants under aerobic or anaerobic conditions.

- Chemical Dosing

- The controlled addition of chemicals to a process to adjust pH, oxidize contaminants, or improve separation efficiency.

- Clean-in-Place (CIP)

- An automated cleaning process used in food, beverage, and pharmaceutical systems to sanitize equipment without disassembly.

- Combustion Control

- The optimization of fuel and air input in burners or engines to maximize efficiency and minimize emissions.

- Desalination

- A water treatment process that removes salts and minerals from seawater or brackish water to produce potable water.

- Disinfection

- The process of eliminating or deactivating pathogens in water, often using chlorine, ozone, or ultraviolet light.

- Effluent

- Treated or untreated wastewater that flows out of a facility, which must meet regulatory standards before discharge.

- Emission Compliance

- Adherence to environmental regulations governing the release of pollutants into air or water from industrial processes.

- Flotation

- A separation technique in mineral processing where hydrophobic particles are floated and separated from hydrophilic material.

- Gas Detection

- The identification and measurement of potentially hazardous gases in industrial environments to protect personnel and equipment.

- Membrane Filtration

- A water purification method that uses semi-permeable membranes to separate impurities, often used in RO and UF systems.

- Nutrient Removal

- The process of eliminating nitrogen and phosphorus from wastewater to prevent eutrophication in receiving waters.

- Oxidation-Reduction Potential (ORP)

- A measure of a solution’s ability to act as an oxidizing or reducing agent, used to control disinfection and chemical reactions.

- Process Optimization

- The ongoing improvement of industrial operations to increase efficiency, product quality, and cost-effectiveness.

- Regulatory Monitoring

- The use of instrumentation and sampling to document compliance with local, state, or federal environmental standards.

- Residual Disinfectant

- The remaining concentration of disinfectant (e.g., chlorine) in water after treatment, used to prevent microbial regrowth.

- Slurry

- A semi-liquid mixture of solids and liquid, common in mineral processing and requiring careful monitoring for effective handling.

- Source Water

- The raw, untreated water collected from surface or groundwater sources for municipal or industrial use.

- Stack Emissions

- Airborne pollutants released through industrial stacks or vents, typically regulated for NOx, SO₂, CO, and particulate matter.

- Tailings

- The residual material left after the valuable fraction has been separated from ore, usually stored in ponds or impoundments.

- Wastewater Reuse

- The process of treating and repurposing wastewater for non-potable or even potable applications, reducing water demand.

- Water Quality Monitoring

- The ongoing measurement of chemical, physical, and biological parameters to assess and ensure water safety and compliance.

Frequently Asked Questions

How do I choose the right analyzer for my application?

The right analyzer depends on the process conditions, the specific parameter to be measured, required accuracy, regulatory requirements, and installation environment. Clipper Controls can assist with application review and specification to ensure proper selection.

What support does Clipper Controls offer for analyzer systems?

Clipper Controls offers application engineering, product selection assistance, system integration support, startup and commissioning services, and ongoing technical support. We help ensure your analyzer solution is installed correctly and performing reliably over time.

Do analyzers require regular maintenance or calibration?

Can analyzers be integrated with SCADA or PLC systems?

What industries benefit the most from gas and liquid analyzers?

Analyzers are critical in power generation, water and wastewater treatment, semiconductor manufacturing, chemical processing, food and beverage production, pharmaceuticals, and mining. They provide the data needed to ensure product quality, process efficiency, and environmental compliance.

Are analyzers affected by temperature, pressure, or contaminants?

Yes. Process conditions such as high temperature, pressure fluctuations, or fouling substances can impact analyzer performance. It’s important to select models rated for the specific conditions and to consider protection measures like sample conditioning, isolation valves, or thermal shielding when necessary.