Inline Moisture Analyzers

Trace Moisture Monitoring in Industrial Processes

👉 Schedule a consultation with Clipper Controls to learn more about reliable inline moisture analyzers.

From Manual Sampling to Continuous Inline Monitoring

- Time delays: Laboratory analysis can take hours or even days, making it impossible to respond quickly to changing conditions.

- Labor intensive: Manual sampling requires staff resources, creating operational inefficiencies.

- Accuracy risks: Improper sampling or handling can produce misleading results, exposing facilities to unnecessary risks.

- Reduce downtime by identifying issues before they escalate into costly failures.

- Protect equipment by keeping moisture within safe limits, reducing corrosion and wear.

- Improve process control with immediate feedback for operational adjustments.

- Ensure compliance with industry standards and environmental regulations.

👉 Give us a call at (844) 880-2469 to discuss your process and moisture monitoring goals.

Key Applications Across Industries

Inline moisture analyzers are not confined to one sector. Their ability to deliver continuous, real-time moisture data makes them indispensable across a wide range of industrial processes.

Natural Gas Processing

Hydrate prevention: Inline analyzers help prevent hydrate formation, which can clog pipelines and interrupt flow.

Corrosion protection: By keeping moisture at safe levels, operators extend the life of compressors, pipelines, and storage systems.

Regulatory compliance: Consistent monitoring ensures gas meets export specifications and industry standards.

Mining Operations

Slurry management: Monitoring water content in slurries ensures efficient separation and concentration of valuable minerals.

Equipment protection: By avoiding moisture-induced wear, operators minimize downtime and extend asset lifespan.

Regional relevance: In Nevada and other mining-heavy regions, moisture analyzers help operators meet both efficiency and compliance demands.

Chemical and Manufacturing Plants

Process optimization: Inline analyzers help operators maintain strict control over raw materials and reaction conditions.

Contamination prevention: Accurate, real-time data reduces the risk of defective batches and compliance failures.

Broad applicability: From plastics and polymers to pharmaceuticals and specialty chemicals, moisture control is key to meeting high production standards.

Across industries, the benefits are the same: reduced downtime, extended equipment life, higher product quality, and stronger regulatory compliance.

👉 Schedule a call with a Clipper Controls specialist to review your application needs.

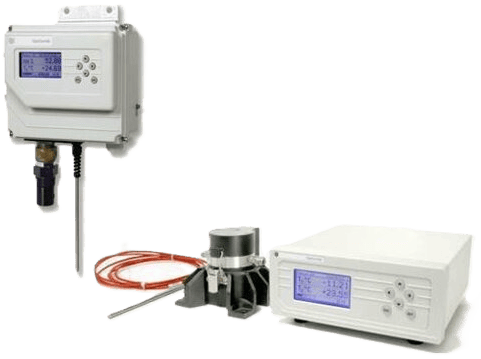

Panametrics Inline Moisture Analyzers

👉 Contact Clipper Controls to learn more about Panametrics inline moisture analyzers and how they can protect your operation.

Compliance, Safety, and Environmental Benefits

Choosing the Right Analyzer for Your Operation

Selecting an inline moisture analyzer is not a one-size-fits-all decision. Each process environment presents unique challenges, and the right instrument must balance accuracy, durability, and ease of integration.

Factors to Consider When Selecting an Analyzer

Process medium: The type of gas or liquid being measured directly impacts sensor compatibility.

Environmental conditions: Temperature extremes, high pressure, or abrasive materials demand rugged instrumentation.

Accuracy requirements: High-value processes may require ultra-precise readings, while others prioritize reliability over resolution.

Maintenance needs: Choosing analyzers designed for minimal upkeep reduces lifecycle costs and downtime.

Why Expert Guidance Matters

With so many variables, working with an experienced instrumentation partner ensures that your analyzer is properly specified for the application. From natural gas dehydration to chemical processing and mining operations, selecting the correct analyzer protects equipment, improves efficiency, and supports compliance goals.

By partnering with Clipper Controls, operators gain access to proven expertise in specifying Panametrics moisture analyzers and other industrial technologies designed for long-term reliability in demanding environments.

👉 Work with Clipper Controls to select the right inline moisture analyzer for your specific process conditions.