Process Controls

We are Control Freaks! It is in our name. At Clipper Controls, our process control solutions are engineered to deliver precision, safety, and reliability in demanding industrial environments. From motor speed control and PID loop regulation to safety logic and transformer monitoring, our lineup of high-performance components supports advanced automation and real-time system response. We provide trusted technologies for power generation, water treatment, chemical processing, manufacturing, and other critical industries—helping operators maintain stable, efficient, and compliant operations.

Adjustable Speed Drives

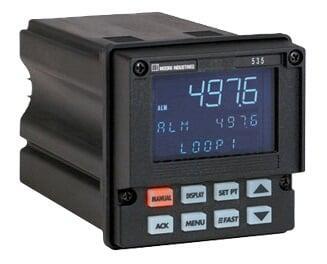

PID Controllers

Our PID controllers are engineered for precise regulation of temperature, pressure, flow, and level in both batch and continuous processes. They feature universal dual inputs compatible with RTDs, thermocouples, mV, current, or voltage signals. With a sampling rate of 10 times per second, they ensure rapid response to process changes. Modular, field-interchangeable outputs—including analog, relay, and solid-state options—provide flexibility for various control strategies. Advanced tuning algorithms adapt to process dynamics, enhancing stability and reducing overshoot. Optional RS-485 communication facilitates integration into broader control systems.

Manual Backup Station

Automatic Flare Management System

Our flare control system enhances combustion efficiency and regulatory compliance by integrating ultrasonic flow measurement with real-time analytics. It calculates net heating value (NHV) using sound speed data, enabling precise control of steam and fuel gas inputs. The system supports digital verification of flow meters and predictive emissions monitoring, providing continuous insights into combustion efficiency and destruction removal efficiency. This ensures optimal flare operation, reduces methane slip, and aligns with environmental standards.

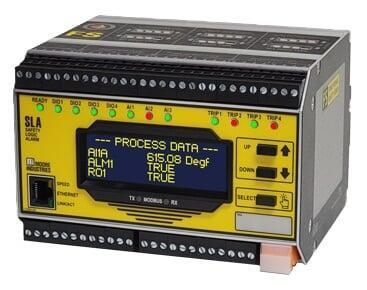

Logic Solvers

Our safety logic solvers are engineered to manage up to three independent safety loops, offering a cost-effective alternative to complex safety PLCs. They accept six analog inputs and four discrete inputs, supporting various sensor types including current, voltage, RTD, thermocouple, resistance, and millivolt signals. With 16 configurable internal alarms, four relay outputs, and optional analog outputs, they enable advanced voting schemes (1oo2, 2oo3, 5oo8) and custom logic functions. Certified for SIL 2/3 applications per IEC 61508, our solvers ensure high-integrity safety performance. Features like HART pass-through, embedded web server, and MODBUS/TCP communication facilitate seamless integration and diagnostics.

Transformer Temperature Monitoring & Control

Our transformer temperature monitoring systems provide precise measurement of top oil, winding, and ambient temperatures using platinum RTD sensors. They support up to three temperature channels and accept inputs from thermowell or magnetic probes. Features include up to 11 configurable relay outputs for alarms and cooling control, analog retransmission of temperature data, and communication via RS-232, RS-485, or Ethernet protocols. Advanced models offer calculated winding temperature based on load current and oil temperature, enhancing transformer protection and operational efficiency.

Alarm Trips

Our alarm trips provide reliable on/off control, early warning, and emergency shutdown capabilities when monitored process signals exceed user-defined high or low limits. They accept a wide range of inputs, including 4–20mA, 0–10V, RTDs, and thermocouples, and offer up to four configurable relay outputs. Features include adjustable deadbands, programmable trip delays, and optional analog retransmission. DIN-rail mounting and universal power inputs simplify integration into existing systems.

Programmable Logic Controllers (PLC)

Our programmable logic controllers offer scalable control for applications ranging from standalone machines to complex process systems. We support up to 144 discrete and 56 analog I/O points, with modules available for RTD, thermocouple, pulse width modulation, and high-speed counting. Onboard Ethernet and serial ports enable integration via Modbus TCP/IP, while advanced instruction sets, including floating-point math and indirect addressing, deliver robust process logic capability.

Human Machine Interfaces (HMI)

Our human-machine interfaces (HMIs) offer intuitive control and monitoring for industrial systems. Featuring 7" to 12" color touchscreens with 800×480 resolution, they support resistive touch input and provide clear visualization of process data. Equipped with Ethernet, USB, and serial ports (RS-232/422/485), our HMIs facilitate seamless integration with PLCs and other devices. Operating on a Linux-based system with 1 GHz processors, they ensure responsive performance and reliable operation in demanding environments.

Wastewater Biological Treatment Optimization

Ekster & Associates provide an ingenious control system that sits on top of your existing infrastructure to synergistically optimize plant capacity, water quality and minimize energy consumption, all at the same time, thru a unique machine learning of your specific plant capabilities. Not being a one size fits all software package, they achieve the highest possible optimization available in the WWTP market for model predictive control systems. Looking at energy savings alone, typical ROI is just 8 months. In addition to the huge energy savings, another major benefit is higher water treatment capacity while complying with ever stricter water quality regulations. This could delay the need for a very costly plant expansion for decades.

Need Help?

Our Crew is Here To Serve You!

Process Controls Applications

Chlorination and Dechlorination

Chlorination and dechlorination are critical processes in water and wastewater treatment, ensuring effective disinfection and compliance with environmental regulations. Precise control and monitoring of chlorine dosing and residuals are essential to protect public health and aquatic life. Advanced instrumentation enables accurate dosing, real-time monitoring, and efficient control of these processes.

Recommended Products

Crystallization Process Control

Crystallization is a critical step in sugar refining and other chemical processes where controlling crystal growth, size, and shape directly impacts product quality and yield. Traditional sampling methods are labor-intensive and offer delayed feedback, which can lead to off-spec batches and inconsistent results. A real-time optical monitoring system enables operators to visualize crystal formation and optimize supersaturation and seeding strategies with immediate feedback.

Recommended Products

Fiberglass Bat Length & Width Control

In fiberglass insulation manufacturing, controlling the dimensions of batts—specifically length, width, and thickness—is essential to ensure quality, reduce material waste, and meet strict customer specifications. Manual inspection methods and basic photo-eye sensors often lack the resolution and reliability needed for real-time dimensional control. A vision-based measurement system provides continuous, non-contact monitoring to ensure each batt remains within tolerance throughout production.

Recommended Products

Flare Management and Compliance

Effective flare management is essential for minimizing emissions, ensuring safety, and complying with environmental regulations. Modern systems focus on optimizing combustion efficiency, reducing methane slip, and maintaining continuous monitoring to meet standards such as EPA's 40 CFR 63.670.

Recommended Products

Foam Level Control

Recommended Products

Molten Glass Level Control

Maintaining a consistent molten glass level is essential for quality control in glass manufacturing. Variations in level can lead to product defects, inefficient furnace operation, and downstream forming issues. Traditional level sensors struggle in the extreme temperatures and radiant environments of glass furnaces. A non-contact, vision-based system offers precise and repeatable level measurements without being affected by heat, vapor, or slag buildup.

Recommended Products

Spray Dryer Control

Spray dryers are critical in converting liquid feeds into dry powders, commonly used in food, pharmaceutical, and chemical processing. Precise atomization is vital to ensure consistent particle size, prevent wall buildup, and avoid safety hazards such as fires or explosions. Traditional monitoring methods rely on indirect indicators and offer no visibility into spray behavior. Implementing a real-time visual monitoring system helps operators identify nozzle clogging, drift, or malformed spray patterns before they affect product quality or system safety.

Recommended Products

Transformer Temperature Control

Recommended Products

Wastewater Biological Treatment

Recommended Products

Terms & Definitions

- 4–20 mA Signal

- A standard analog signal range used for transmitting measurements from field devices to controllers or recorders in industrial automation.

- Alarm Trip

- A device that activates an alert or safety mechanism when a process variable exceeds or falls below a specified threshold.

- Batch Control

- A control method where processes are executed in distinct, repeatable sequences, often used in chemical, food, and pharmaceutical production.

- Blower Oscillation

- Fluctuations in blower output due to unstable control loops or improperly tuned setpoints, leading to inefficient aeration or mechanical wear.

- CEMS

- Continuous Emissions Monitoring System, used to track and record air pollutants released from industrial sources for environmental compliance.

- Crystallization

- A process where solid crystals form from a solution, melt, or vapor—commonly used in sugar refining and chemical processing.

- Deadband

- A range around a setpoint where no control action is taken, used to prevent frequent switching or oscillation in control systems.

- Dechlorination

- The process of removing chlorine from water, typically using sulfur dioxide or other neutralizing agents, before discharge into the environment.

- Destruction Removal Efficiency (DRE)

- A measure of how effectively a flare or incinerator destroys volatile organic compounds or other hazardous pollutants.

- Dew Point

- The temperature at which air becomes saturated with moisture and water vapor begins to condense—critical in compressed air systems.

- Dissolved Oxygen (DO)

- The amount of oxygen present in water, essential for biological treatment processes and monitored to optimize aeration control.

- Dry Contact

- A contact that does not supply voltage; it only opens or closes a circuit and is commonly used in alarm relays or trip mechanisms.

- Foam Control

- Techniques or systems used to detect and suppress foam in bioreactors, fermenters, or treatment basins, often using optical sensors or antifoam injection.

- Human Machine Interface (HMI)

- A graphical user interface that allows operators to interact with automated systems, view process data, and issue control commands.

- Logic Solver

- A safety-rated control system used to evaluate process inputs and determine appropriate output actions in safety instrumented systems.

- Molten Glass Level

- The controlled level of liquid glass in a furnace, measured with optical systems to ensure consistent flow and product quality.

- Modbus TCP/IP

- A widely used industrial communication protocol that enables Ethernet-based connectivity between control systems and field devices.

- Model Predictive Control (MPC)

- An advanced control strategy that uses mathematical models to forecast future process behavior and optimize control actions in real time.

- PLC (Programmable Logic Controller)

- A rugged digital computer used for automation of industrial processes, featuring real-time input/output control and logic-based programming.

- PID Controller

- A control device that uses proportional, integral, and derivative functions to maintain a process variable at a desired setpoint.

- SCADA

- Supervisory Control and Data Acquisition system used for centralized process control, data acquisition, and remote monitoring in industrial settings.

- SRT (Sludge Retention Time)

- The average time that solids remain in an activated sludge system, a key variable in biological wastewater treatment.

- TDLAS

- Tunable Diode Laser Absorption Spectroscopy, a laser-based gas measurement technique used for ultra-precise moisture and gas analysis.

- Vision-Based Measurement

- A non-contact sensing technique using cameras and image analysis to determine position, dimension, or level in industrial processes.

Need Help?

Our Crew is Here To Serve You!

Services We Offer

Instrumentation Calibrations

Rental Equipment

Equipment Troubleshooting

Repairs & Maintenance

Instrumentation

Flow Studies

Startup & Training

Products

Applications

Resources

Brands We Recommend