Automatic Water Samplers

Automatic water samplers are essential tools for collecting accurate water samples in a variety of environments, including industrial, environmental, and municipal applications. Designed for precision and durability, these devices ensure reliable data collection for analysis of water quality, contaminants, and compliance with regulatory standards.

Models are available as either portable or fixed units, with options for refrigeration, composite or sequential sampling, and AC, battery, or solar power. Each sampler is designed for specific environments and sampling requirements, ensuring accurate and efficient water quality monitoring.

To inquire about our products or to request a quote, please contact us.

Featured Automatic Water Samplers

Water samplers play a crucial role in environmental monitoring, regulatory compliance, and industrial applications. Various types of water samplers exist, each designed for specific sampling needs. Below is a comparison of the most common types of water samplers and their applications.

Automatic Water Sampler

Automatic water samplers are designed to collect water samples at predetermined intervals without manual intervention. They are often used in long-term monitoring programs.

Key Features:

- Programmable collection intervals

- Suitable for remote and unattended sampling

- Can be configured for composite or sequential sampling

Common Applications:

- Continuous environmental monitoring

- Regulatory compliance sampling

- Industrial water quality testing

Portable Water Sampler

Portable water samplers are lightweight and designed for easy transport, making them ideal for fieldwork and short-term sampling needs.

Key Features:

- Compact and battery-powered

- Easy to carry for on-site sampling

- Can support composite or discrete sampling

Common Applications:

- Stormwater monitoring

- Field research studies

- Short-term sampling projects

Refrigerated Water Sampler

Automatic water samplers are designed to collect water samples at predetermined intervals without manual intervention. They are often used in long-term monitoring programs.

Key Features:

- Programmable collection intervals

- Suitable for remote and unattended sampling

- Can be configured for composite or sequential sampling

Common Applications:

- Continuous environmental monitoring

- Regulatory compliance sampling

- Industrial water quality testing

Composite Sampler

Key Features:

- Can be time-based or flow-proportional

- Reduces variability in sample analysis

- Ideal for long-term trend analysis

Common Applications:

- Regulatory compliance in wastewater treatment

- Industrial effluent monitoring

- Stormwater runoff analysis

Sequential Sampler

Key Features:

- Enables tracking of pollutant fluctuations

- Ideal for identifying pollution sources

- Provides detailed temporal data

Common Applications:

- Studying contamination trends over time

- Industrial process monitoring

- Environmental impact assessments

Wastewater Autosampler

Key Features:

- Robust construction for handling harsh environments

- Capable of composite or discrete sampling

- Often integrated with flow meters for precise collection

Common Applications:

- Wastewater treatment facility compliance

- Industrial discharge monitoring

- Regulatory sampling in municipal sewage systems

Need Help?

Our Crew is Here To Serve You!

How Automatic Water Samplers Work

Automatic water samplers are devices designed to collect water samples at programmed intervals or under specific conditions without the need for constant human supervision. These systems are widely used in environmental monitoring, industrial compliance, research, and municipal applications to evaluate water quality, pollutant levels, or water treatment process efficiency. By automating the sampling process, they help ensure consistency, accuracy, and representative data over extended periods, even in remote or hazardous locations.

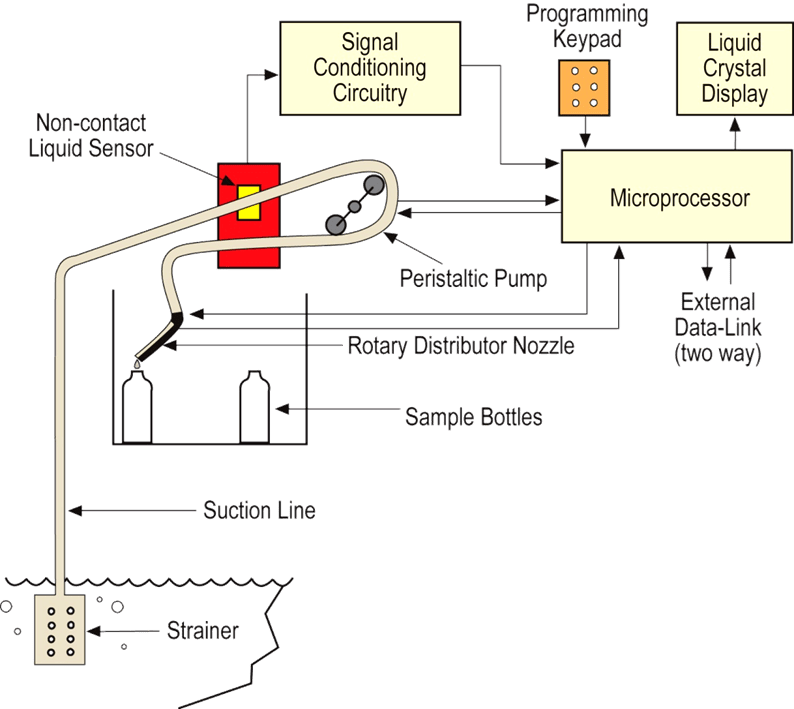

Key Components of Automatic Water Samplers

Automatic water samplers are made up of several essential components that work together to collect, store, and preserve water samples:

- Sampling Intake System

Includes a strainer, suction line, peristaltic pump, and a non-contact liquid sensor, that draws water from the source to the sampler and pours the measured water sample into the sample bottles through a discharge tube. - Sample Collection Containers

Holds the collected water which comes from the pump discharge tube; these may be single composite containers or multiple discrete bottles, depending on the application. - Control and Programming Unit

A programmable controller or interface that allows users to set sampling schedules, triggers, and volumes, and to log operational data. - Enclosure and Environmental Protection

The housing protects internal components from environmental conditions like rain, heat, cold, or vandalism, and varies between stationary and portable designs with additional options for sample ice cooling, sample refrigeration, and pump assembly heating.

Sampling Methods and Mechanisms

Automatic samplers can be programmed to operate using various sampling strategies to match monitoring needs:

- Time-Based Sampling

Collects samples at fixed time intervals (e.g., every 15 minutes, hourly, or daily), ideal for routine monitoring. - Flow-Proportional Sampling

Triggers sample collection based on flow volume or velocity, ensuring that collected samples represent varying flow conditions, such as in wastewater discharge. - Event-Based Sampling

Initiates sampling in response to specific events or threshold conditions, such as rainfall, pH shifts, conductivity changes, or pollutant spikes, making it useful for stormwater or spill monitoring.

Types of Water Samplers

There are several types of water samplers designed to meet different site requirements and sampling goals:

- Portable Samplers

Lightweight, compact units designed for flexible use in the field, often powered by batteries or solar panels. - Stationary Samplers

Permanently installed units at fixed sites, commonly used in treatment plants or industrial facilities, typically with access to AC power. - Refrigerated Samplers

Equipped with cooling systems to preserve temperature-sensitive samples, ensuring accurate analysis for parameters like biological oxygen demand (BOD) or nutrient levels. - Composite vs. Discrete (Bottle) Samplers

Composite samplers collect multiple samples into a single container to create an averaged sample over time, while discrete samplers collect individual samples into separate bottles, allowing for time- or flow-specific analysis.

Integrated Technologies and Measurement Modules

Automatic water samplers can be enhanced with various technologies and modules to expand their capabilities and improve data collection:

- Flow Modules

Measure flow using technologies such as area velocity, ultrasonic, electromagnetic, or bubbler systems to support flow-proportional sampling and monitor hydraulic conditions. - pH and Temperature Sensors

Monitor water chemistry and thermal conditions, enabling event-based sampling when specific thresholds are reached. - Analog and Digital Input Modules

Accept external signals from a variety of instruments, allowing the sampler to respond to conditions like rainfall events, level changes, or external controller commands. - Communication Interfaces

Use interfaces such as RS-485, Modbus, or SDI-12 to integrate with SCADA systems, data loggers, or telemetry units for remote monitoring and control. - Data Logging and Telemetry Systems

Enable storage and transmission of operational data and sampling events to central systems or cloud-based platforms for analysis and reporting.

Power Options for Operation

Water samplers offer flexible power solutions to suit different field conditions and site requirements:

- Battery-Powered Systems

Operate on rechargeable or replaceable batteries, providing mobility and independence for remote or temporary deployments. - Solar Power Integration

Use solar panels to maintain battery charge and extend operating life in off-grid or remote locations. - AC-Powered Systems

Connect to standard electrical outlets for continuous power supply, typically used at permanent installations like treatment plants or industrial facilities. - Hybrid Power Configurations

Combine multiple power sources (e.g., battery and solar, or battery and AC) to maximize uptime and reliability under variable conditions.

Sample Preservation and Quality Control

Proper preservation and quality control are essential to ensure that collected water samples remain representative and meet laboratory standards for analysis.

- Refrigerated Storage

Keeps samples at controlled temperatures to prevent biological or chemical changes, especially important for parameters like nutrients, BOD, or bacteria counts. - Stirring or Agitation Systems

Maintain uniformity in the composite container, preventing solids from settling and ensuring consistent sample quality. - Overflow and Purge Controls

Prevent cross-contamination between samples by purging lines and managing overflow, ensuring clean and representative sample collection.

Installation Considerations

Choosing the right installation setup is key to reliable sampler performance and ease of maintenance.

- Indoor vs. Outdoor Placement

Outdoor installations require rugged enclosures and environmental protection, while indoor setups may prioritize accessibility and integration with facility systems. - Above-Ground vs. Below-Ground Mounting

Samplers can be mounted above ground for easy access or placed in below-ground vaults to protect against freezing, vandalism, or environmental exposure. - Accessibility for Maintenance and Bottle Change

Install samplers in locations that allow safe, convenient access for routine maintenance, programming adjustments, and sample retrieval.

Water Sampler Applications

Automatic water samplers are used across a wide range of applications to monitor water quality, meet regulatory requirements, and support environmental research.

NPDS Permit Compliance

Automatic samplers play a key role in helping facilities meet National Pollutant Discharge Elimination System (NPDES) permit requirements. Water samplers support regulatory compliance by enabling accurate, time-based or flow-weighted composite sampling of effluent discharges. With modular options and rugged enclosures, these systems are ideal for long-term deployment at outfalls, treatment plant discharge points, and other regulated locations. Reliable sample collection ensures defensible data for reporting, auditing, and enforcement response.

Stormwater

Managing stormwater runoff is critical for both regulatory compliance and environmental protection. Our stormwater sampling equipment is trusted for stormwater monitoring programs, offering reliable performance during unpredictable weather events. Designed to trigger on rainfall, flow, or level thresholds, stormwater samplers capture first-flush events and composite samples over the duration of a storm. With options for portable or permanent installation, they provide the flexibility needed for municipal, industrial, and construction site runoff monitoring.

Process Monitoring & Optimization

In industrial and municipal facilities, automatic samplers support continuous improvement by capturing representative samples from key process streams. Automatic samplers help identify variability, optimize chemical dosing, and verify treatment performance over time. Whether integrated into a SCADA system or configured for standalone operation, these samplers deliver high-resolution data for process control decisions and troubleshooting. With modular communication options and corrosion-resistant materials, they’re built to handle demanding environments.

Wastewater-Based Surveillance (WBS)

Wastewater-Based Surveillance (WBS) is an emerging tool for tracking public health trends through the analysis of sewage. Our wastewater autosamplers are widely used by universities, municipalities, and public health agencies to collect time-weighted or flow-proportional samples for pathogen and biomarker analysis. With programmable schedules, remote communication options, and rugged designs, wastewater samplers provide consistent, high-quality samples needed for viral load monitoring, epidemiological studies, and early warning systems.

Per- and Polyfluoroalkyl Substances (PFAS)

Monitoring for Per- and Polyfluoroalkyl Substances (PFAS) requires sampling equipment that minimizes contamination and preserves sample integrity. A type of automated water sampler we offer, is designed with PFAS-compatible components and customizable configurations to meet stringent sampling protocols. Whether deployed for regulatory compliance, source tracking, or research, these samplers enable accurate time-based or flow-weighted composite collection in municipal, industrial, and environmental applications. Paired with proper sample handling, they support defensible data generation for this critical class of emerging contaminants.

Drinking Water Plant Sampling for Fluoride

Routine monitoring of fluoride levels in drinking water treatment plants is essential for public health and regulatory compliance. Automatic samplers streamline this process by collecting reliable, consistent samples from finished water or intermediate stages. With programmable schedules and precise volume control, they reduce manual sampling burden while ensuring traceable fluoride data. Durable construction and compatibility with treated water make them ideal for long-term use in drinking water applications.

Industrial Pretreatment

Automatic samplers are essential for monitoring industrial users contributing to a municipal wastewater system. Samplers help enforce pretreatment standards by collecting representative flow-weighted or time-based samples at discharge points. With rugged enclosures and flexible programming, they can withstand harsh environments and irregular flow conditions. These systems support defensible data collection for compliance, surcharge billing, and enforcement, protecting treatment plant operations and downstream water quality.

Stream Monitoring

Automatic samplers support stream monitoring programs by enabling unattended sample collection in remote and challenging environments. Whether tracking seasonal changes, pollutant loading, or upstream/downstream impacts, these samplers offer time-based and event-triggered sampling for comprehensive data sets. With battery power options, rugged weatherproof housings, and modular accessories like rain gauges and flow modules, they’re ideal for long-term deployment in watershed studies and environmental assessments.

Watershed Monitoring

Understanding water quality across a watershed requires consistent, high-quality sampling from multiple locations. Our portable and stationary automatic samplers provide a reliable solution for capturing spatial and temporal data across streams, tributaries, and discharge points. With remote communications, solar power options, and rugged enclosures, they support year-round deployment in challenging field conditions. Ideal for tracking nutrient loading, land use impacts, or regulatory compliance, our samplers help researchers and agencies make informed watershed management decisions.

Water Sampler Comparison Table

Below you can find some of the water samplers we have available. If you need help finding the right water sampler for your needs, our team is ready to learn your needs and share important purchasing considerations for your application. Send us a message or give us a call at (884) 880-AHOY(2469).

| Model | Mobility | Sample Type | Bottle Options | Power Options | Cooling Options | Typical Use Case |

|---|---|---|---|---|---|---|

| ISCO 6712c | Portable | Composite / Discrete | 1*2.5 gal, 24*500mL | AC (standard), AC Battery backup, 12V Battery, 12v Solar | Ice-cooling | Advanced programming, Wastewater, Stormwater, Water quality monitoring |

| ISCO 6712 | Portable | Composite / Discrete | 1*2.5 gal, 4*1 gal, 8*2L, 12*1L, 24*1L | 12V Battery, AC | Ice-cooling | Advanced programming, Wastewater, Stormwater, Water quality monitoring |

| ISCO 6712 Jumbo | Portable | Composite / Discrete | 1*5.5 gal, 1*2.5 gal, 4*1 gal, 8*2L, 12*1L, 24*1L | AC (standard), 12V backup | Ice-cooling | Advanced programming, Wastewater, Stormwater, Water quality monitoring |

| ISCO 6712FR | Stationary | Composite / Discrete | 1*5.5 gal, 2*2 gal, 1*2.5 gal, 4*2.5 gal, 24*1L | AC (Standard), 12V Battery | Refrigerated | Wastewater |

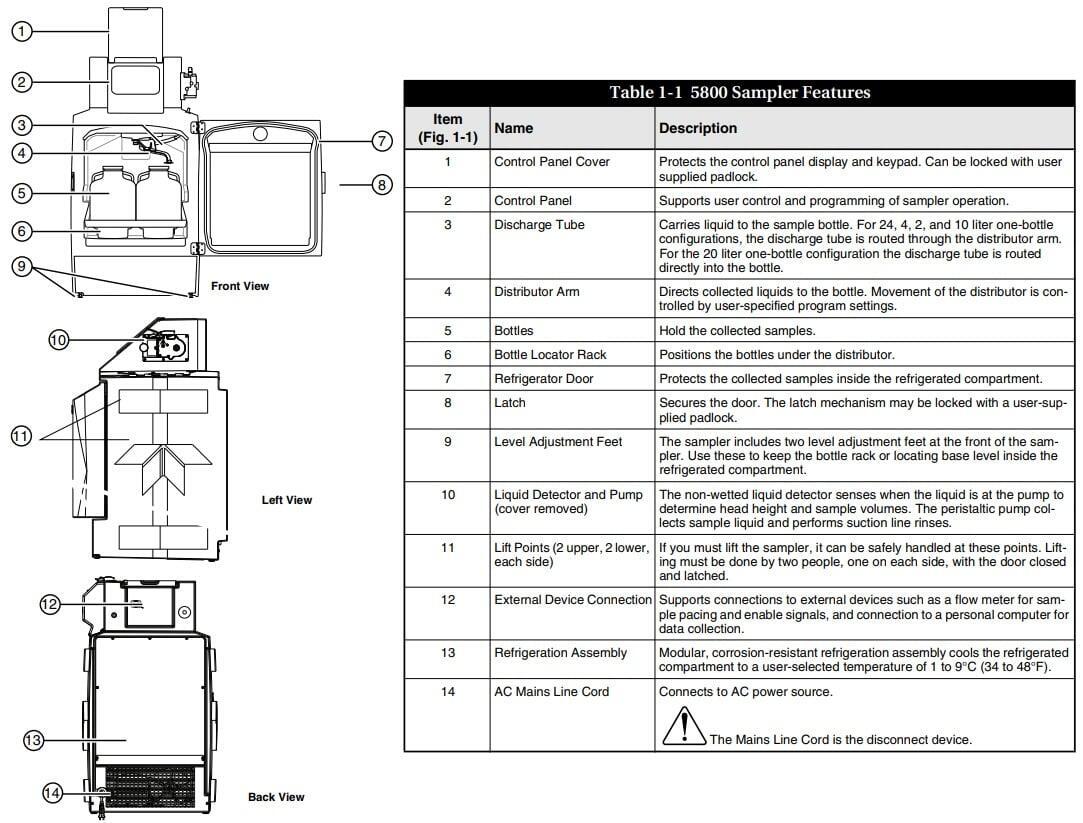

| ISCO 5800 | Stationary | Composite / Discrete | 1*5.5 gal, 1*5 gal, 1*2.5gal, 2*2.5 gal, 4*2.5 gal, 24*1L, 24*350mL | AC (Standard), Battery backup | Refrigerated | Advanced programming, Wastewater |

| ISCO BLZZRD | Portable | Composite / Discrete | 1*5.3 gal, 1*2.5 gal, 4*5L, 4*1.8L, 14*950mL | AC (Standard), 12V Battery, Battery backup | Refrigerated | Advanced programming, Stormwater, Water quality monitoring |

| ISCO GLS | Portable | Composite (limited Discrete) | 1*1 gal, 1*2.5 gal | 2 gal ProPak bags | 12V Battery only | Ice-cooling | Stormwater |

| ISCO 3700 *Discontinued | Portable | Composite / Discrete | 1*2.5 gal, 24*1L | 12V Battery, AC, AC battery backup, Solar | Ice-cooling | Wastewater, Stormwater |

| ISCO 4700 *Discontinued | Stationary | Composite / Discrete | 1*2.5 gal, 24*1L | AC Only | Refrigerated | Advanced programming, Wastewater |

Calculators

Water Sampler Pulse Calculator

Gallons per Pulse: –

# of Pulses per Sample: –

Frequently Asked Questions

What is a water sampler?

A water sampler is a device used to collect water samples for environmental monitoring, compliance testing, and research. These samplers help ensure accurate water quality analysis by preserving samples for laboratory testing.

What types of water samplers are available?

- Automatic water samplers – These collect samples at scheduled intervals or in response to specific conditions.

- Manual water samplers – These require an operator to collect water samples on-site.

How do automatic water samplers work?

- Sample volume capacity

- Refrigeration for sample preservation

- Flow-based or time-based sampling options

- Portability and power options (battery vs. AC power)

- Weather resistance for outdoor use

Yes, there are portable, battery-powered water samplers designed for fieldwork in remote areas. Many models we carry from Teledyne ISCO also support solar power options for extended operation.

- Placing the intake tubing in the water source at an appropriate depth.

- Connecting the sampler to a power source (battery or AC).

- Programming sampling intervals and triggers.

- Ensuring the sampler is secure and protected from environmental conditions.

- Cleaning and replacing intake tubing as needed.

- Checking pump performance and calibrating settings.

- Verifying sample bottle integrity and refrigeration (if applicable).

- Inspecting for clogs or wear in the sampling mechanism.

Yes, we provide technical support and can assist with troubleshooting, maintenance guidance, and replacement parts if needed.