A Guide to Selecting UV Flame Sensors for GE Gas Turbines

- Rapid response in milliseconds to avoid unsafe fuel accumulation

- Consistent operation in high-heat turbine compartments

- Reliability in steam-injected and low-NOx combustion environments, where traditional sensors may fail

👉 Request a datasheet from Clipper Controls, Reuter Stokes' manufacturer's representative for California, Nevada, and Hawaii.

Key Factors in Selecting UV Flame Sensors for GE Turbines

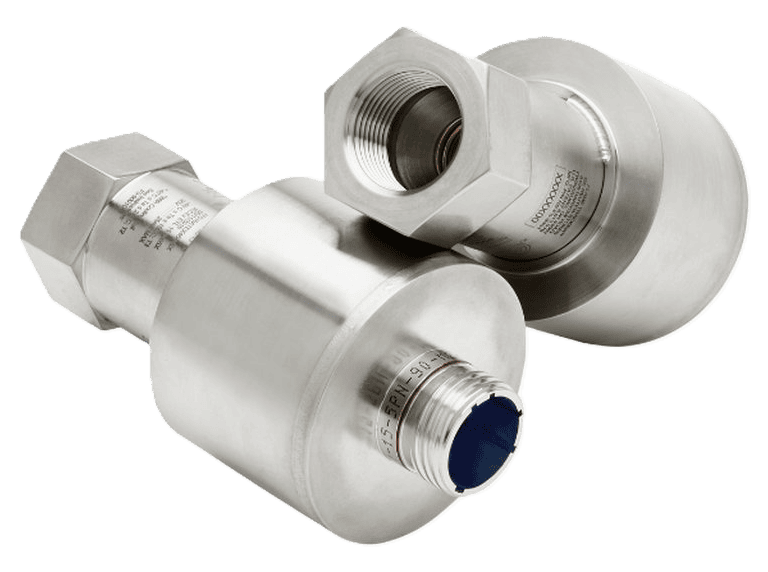

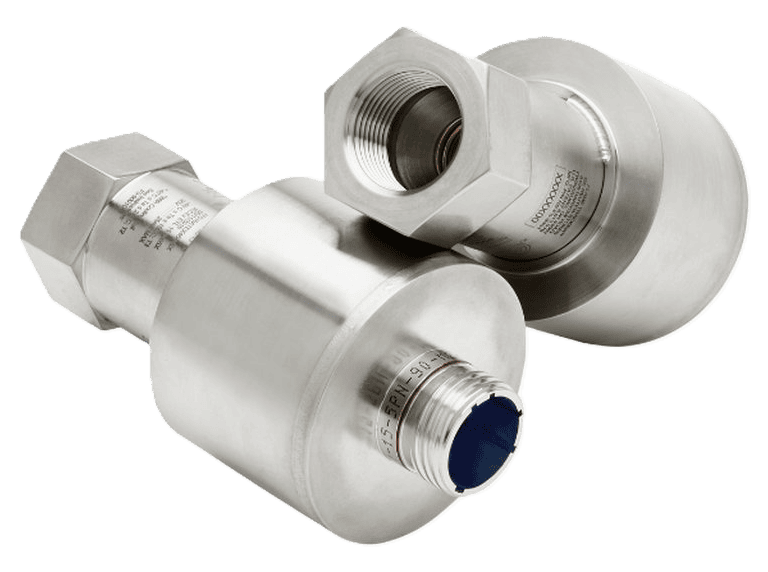

Reuter-Stokes Flame Tracker™ Sensors

Among the available options for GE turbine flame detection, Reuter-Stokes Flame Tracker™ sensors stand out as a proven, OEM-trusted solution. Built on decades of experience in high-reliability UV detection, these sensors are engineered specifically for the operational demands of GE’s aeroderivative turbine fleet.

Advanced Technology: SiC Photodiode Detection

At the heart of the Flame Tracker™ is a silicon carbide (SiC) photodiode, a material known for its high sensitivity to ultraviolet radiation and resistance to thermal degradation. This design allows for detection speeds under 0.025 seconds, ensuring near-instant response to changes in combustion conditions.

Performance in Challenging Conditions

Reuter-Stokes sensors have been field-tested in the toughest environments, maintaining accuracy even in:

Low-NOx combustion systems, where flame signals are weaker

Steam-injected turbines, where moisture can obscure detection

Gas-fog operating conditions, where reliability is often compromised

This robust performance makes them especially valuable for facilities under pressure to meet emissions goals while preserving uptime.

Proven Reliability Worldwide

With more than 500 million operating hours and over 25 years of successful deployment, Flame Tracker™ sensors have earned a reputation for reliability across the global power generation sector. Operators of GE LM2500, LM5000, LM6000, and LMS100 turbines benefit from sensors that consistently perform in both base-load and peaking service.

Trusted Partner for GE Turbine Applications

Because Reuter-Stokes designs specifically for GE turbine compatibility, operators avoid costly trial-and-error with generic alternatives. This alignment with OEM specifications ensures both safety and compliance while simplifying procurement and installation.

👉 Discover the proven reliability of Reuter-Stokes UV flame sensors. Contact Clipper Controls to find the right replacement for your GE turbine model.

Evaluating Suppliers for Lifecycle Value and Reliability

👉 Implement best practices with confidence—get expert field support for flame sensor installation from Clipper Controls.

Page Navigation Links

- Key Factors in Selecting UV Flame Sensors for GE Turbines

- Reuter-Stokes Flame Tracker™ Sensors

- Advanced Technology: SiC Photodiode Detection

- Performance in Challenging Conditions

- Proven Reliability Worldwide

- Trusted Partner for GE Turbine Applications

- Evaluating Suppliers for Lifecycle Value and Reliability