Direct Replacement UV Flame Sensors for GE Gas Turbines

Why Flame Detection Matters in GE Gas Turbines

- Maintain safe turbine operation under varying load conditions

- Optimize fuel usage and combustion efficiency

- Reduce risk of catastrophic failures or extended downtime

- Ensure compliance with industry and OEM safety standards

👉 Request a datasheet from Clipper Controls, Reuter Stokes' manufacturer's representative for California, Nevada, and Hawaii.

Direct Replacement Sensors: Minimizing Downtime and Costs

- Minimized Downtime – Faster availability ensures turbines are back online quickly.

- Reduced Maintenance Costs – Avoid costly emergency repairs and missed generation commitments.

- OEM Compliance – Designed to meet or exceed GE specifications, ensuring combustion safety is never compromised.

- Operational Confidence – Maintenance teams can replace sensors with certainty that performance and reliability are preserved.

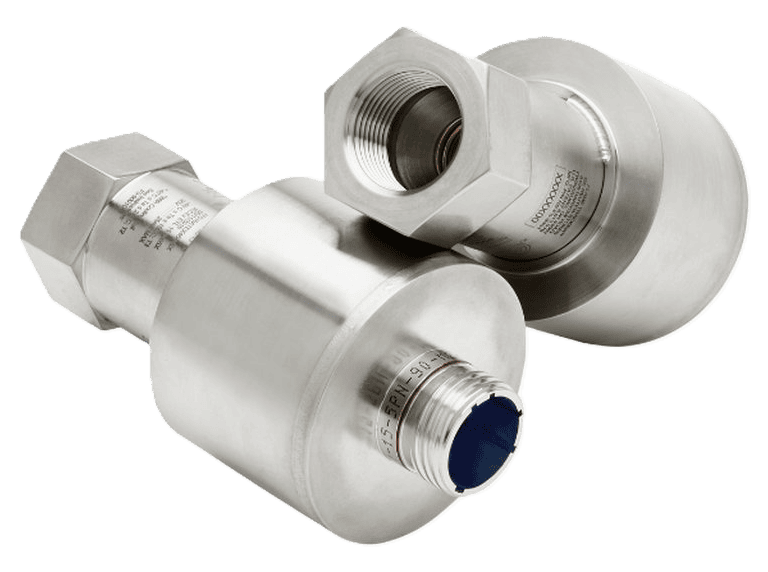

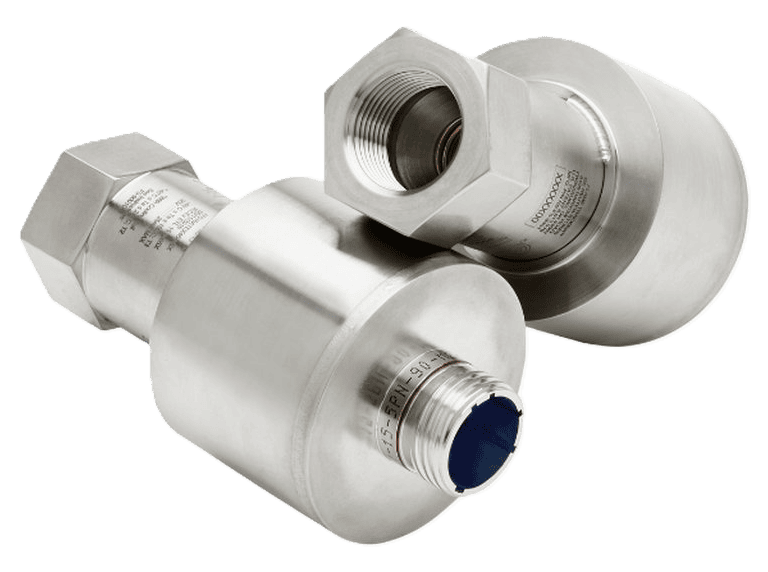

Reuter-Stokes: Proven Reliability in Harsh Environments

- Long service life in high-temperature, high-vibration environments

- Proven compatibility with OEM turbine systems

- Accurate flame detection for stable combustion monitoring

- Lower lifecycle costs through reduced sensor replacement frequency

👉 Discover the proven reliability of Reuter-Stokes UV flame sensors. Contact Clipper Controls to find the right replacement for your GE turbine model.

Installation Best Practices for UV Flame Sensors

- Proper Alignment

- Ensure the sensor has a direct line of sight to the flame.

- Misalignment can lead to false flameout signals or missed detection.

- Secure Mounting

- Vibration is common in turbine environments.

- Use proper brackets and fittings to prevent sensor loosening over time.

- Electrical and Signal Verification

- Confirm proper wiring connections and grounding.

- Check output signals during commissioning to verify sensor responsiveness.

- Calibration and Testing

- Perform functional flame tests after installation.

- Document results to meet compliance and safety audit requirements.

- Routine Inspections

- Regularly inspect lenses for contamination (soot, dust, or oil film).

- Schedule proactive maintenance to reduce the risk of premature failure.

👉 Implement best practices with confidence—get expert field support for flame sensor installation from Clipper Controls.

Common Challenges in Flame Sensor Replacement

Frequent Issues During Replacement:

- Misalignment Errors

- Even slight deviations in positioning can prevent proper flame detection.

- This may lead to false alarms or unnecessary turbine shutdowns.

- Model Compatibility Mistakes

- Installing a sensor not designed for the specific GE turbine model (LM2500, LM5000, LM6000, LMS100) can cause poor performance or system Errors.

- Direct replacements from trusted suppliers prevent this risk.

- Environmental Stress Factors

- High vibration, extreme temperatures, and airborne contaminants often shorten sensor lifespan.

- Using rugged, proven sensors like Reuter-Stokes UV flame sensors helps mitigate premature failure.

- Incomplete Documentation

- Failure to document installations and replacements can create compliance gaps.

- Proper records are essential for audits and OEM maintenance requirements.

Avoiding Repeat Replacements

- Source sensors from trusted suppliers that provide verified compatibility.

- Follow installation best practices for alignment, wiring, and calibration.

- Incorporate preventive inspections into regular maintenance schedules.

Partnering with Trusted Suppliers Like Clipper Controls

Why Clipper Controls?

Authorized Access to Proven Solutions

Clipper Controls provides direct access to Reuter-Stokes UV flame sensors and other OEM-compliant replacements for GE gas turbines.Application Engineering Expertise

Every turbine application has unique operating conditions. Clipper Controls helps maintenance teams identify the right sensor fit, ensuring compatibility with LM2500, LM5000, LM6000, and LMS100 models.Reduced Risk of Costly Errors

With decades of experience in instrumentation and controls, Clipper Controls provides confidence that installations meet OEM standards and compliance requirements.Broader Instrumentation Support

Beyond flame detection, Clipper Controls also supports turbine monitoring, performance data management, and environmental compliance solutions.

By partnering with Clipper Controls, operators gain more than a replacement part—they gain a technical partner committed to keeping their turbines safe, efficient, and compliant.

👉 Get expert guidance on GE turbine flame sensor replacements. Connect with Clipper Controls today.

Page Navigation Links

- Why Flame Detection Matters in GE Gas Turbines

- Direct Replacement Sensors: Minimizing Downtime and Costs

- Reuter-Stokes: Proven Reliability in Harsh Environments

- Installation Best Practices for UV Flame Sensors

- Common Challenges in Flame Sensor Replacement

- Partnering with Trusted Suppliers Like Clipper Controls