Cooling Tower Vibration Monitoring

Cooling towers play a critical role in industrial facilities, ensuring efficient heat rejection for processes in power generation, petrochemical plants, manufacturing, and large-scale HVAC systems. Because these systems operate continuously under harsh conditions, even a minor mechanical issue can escalate into a major disruption.

Unplanned downtime in cooling towers can halt production, compromise product quality, and trigger expensive emergency repairs. Industry studies estimate that unplanned equipment downtime can cost mid- to large-scale industrial facilities—such as chemical plants, food processors, and manufacturing sites—anywhere from $10,000 to $25,000 per hour in lost productivity. In very large, energy-intensive operations like refineries or power plants, those costs can climb significantly higher. Worse, undetected failures in components such as fans, gearboxes, and motors can lead to safety hazards for maintenance personnel and extended outages that ripple across entire facility operations.

Vibration monitoring helps address these challenges by providing early warning of mechanical wear, misalignment, and bearing failure before they cause critical damage. By tracking vibration patterns in real time, operators can detect small anomalies that traditional inspections might miss, ensuring that corrective action is taken proactively rather than reactively.

With cooling tower vibration monitoring in place, facilities gain:

Asset protection — extend the lifespan of fans, gearboxes, and motors.

Operational efficiency — keep cooling systems performing at peak efficiency.

Downtime prevention — avoid unexpected shutdowns that disrupt entire plant operations.

In today’s industrial landscape, where uptime and reliability are key to competitiveness, vibration monitoring for cooling towers is no longer optional — it’s a core part of effective maintenance and reliability strategies.

Learn more about rugged vibration sensors and monitoring technologies at Clipper Controls.

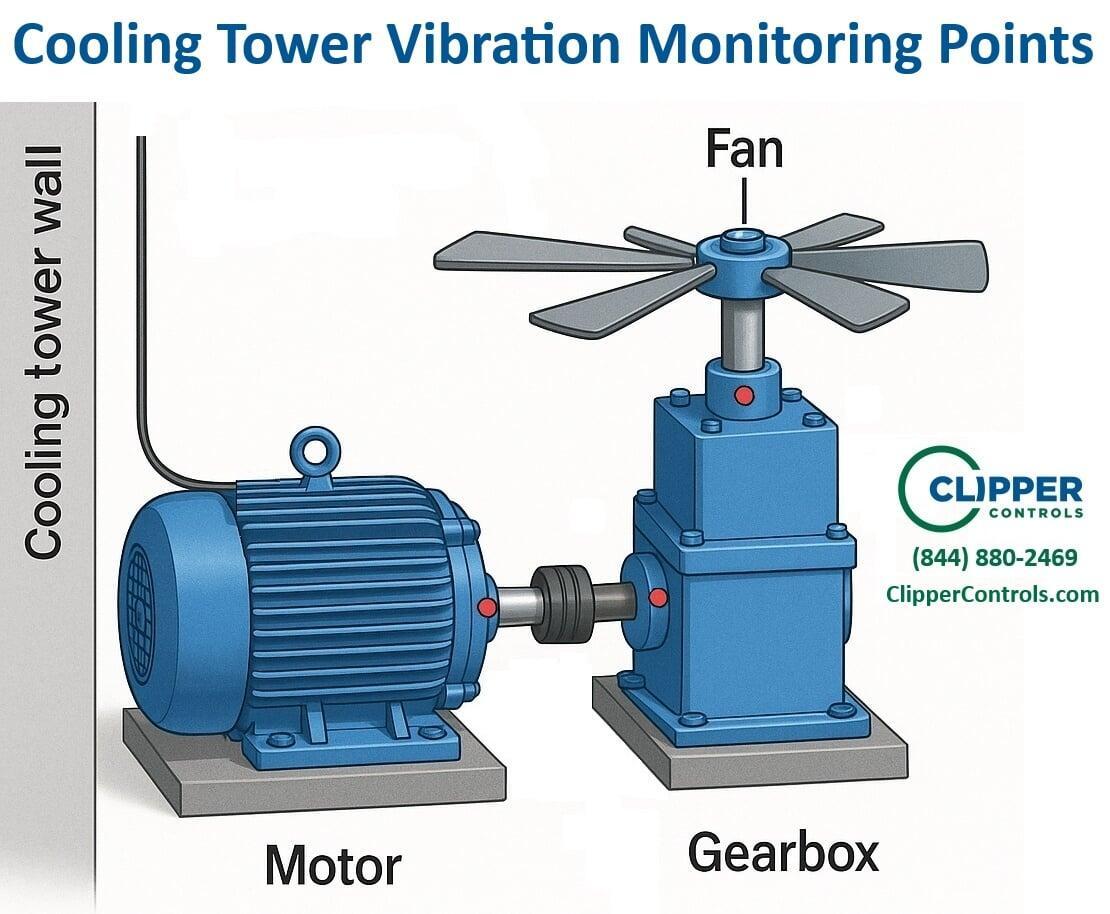

Key Components to Monitor in Cooling Towers

Cooling towers rely on several mechanical components working in unison. If one of these parts begins to degrade, the entire system’s efficiency and reliability are at risk. Vibration monitoring focuses on the most failure-prone components — helping operators detect issues early and plan maintenance before problems escalate.

Fan Assemblies

Gearboxes

Motors

How Vibration Monitoring Enables Predictive Maintenance

- 30–40% reduction in maintenance costs

- 45–55% reduction in unexpected failures

- 20–25% increase in equipment uptime

Advanced Condition Monitoring Technologies for Cooling Towers

Vibration Sensors

- Accelerometers — measure high-frequency vibration, ideal for detecting bearing faults and gear wear.

- Velocity Sensors — commonly used for general machine health monitoring, effective for detecting imbalance and misalignment.

- Displacement Sensors — track shaft motion, helpful for identifying misalignment and looseness in large rotating machinery.

Real-Time Monitoring Systems

- Trend vibration data over time to predict failure points.

- Receive automated alerts when vibration levels exceed safe thresholds.

- Integrate data into facility-wide condition monitoring platforms for a complete asset health view.

Built for Industrial Environments

Our Product Benefits for Cooling Tower Reliability

Rugged, Reliable Sensors

Seamless Integration

Predictive Maintenance Made Practical

Proven Asset Protection

Discover how predictive maintenance powered by vibration monitoring can reduce costs and increase uptime — schedule an on-site demonstration with Clipper Controls.