Integrally Geared Centrifugal Compressor Monitoring

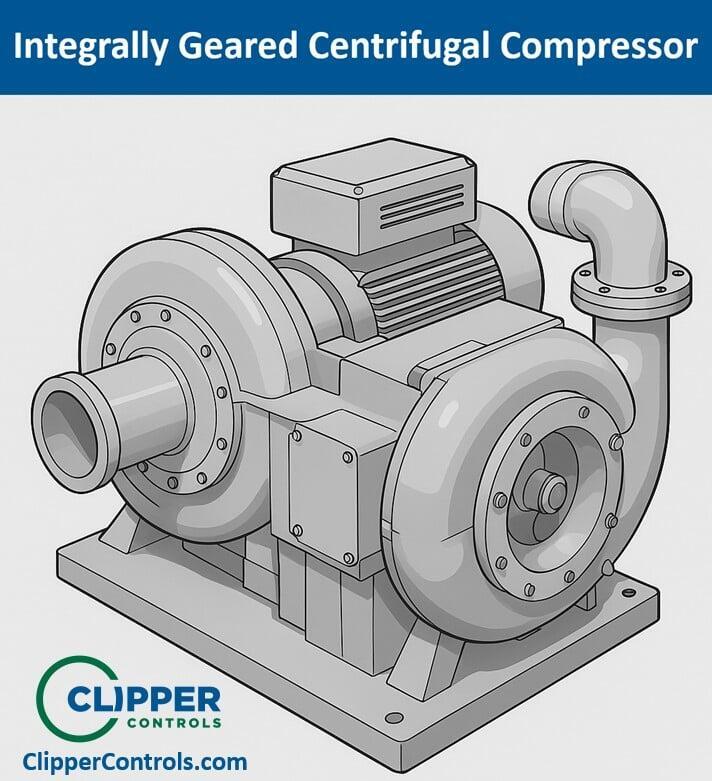

What Are Integrally Geared Centrifugal Compressors (IGCCs)?

Key Advantages of IGCCs

- High Efficiency: By tailoring impeller speeds independently, IGCCs minimize energy losses and achieve superior efficiency compared to single-shaft designs.

- Compact Footprint: The gear-driven design allows for multiple stages in a smaller space, making IGCCs ideal for facilities with limited floor area.

- Operational Flexibility: Independent speed control across stages enables optimized performance for different process conditions.

- Proven Reliability: With proper monitoring and maintenance, IGCCs deliver consistent performance in demanding industrial environments.

Where IGCCs are Used

- Petrochemicals & Refining: Supporting processes that demand continuous, reliable gas compression.

- Power Generation: Providing compressed air for turbines and other auxiliary systems.

- Manufacturing & Utilities: Ensuring efficient plant operation through stable and reliable compressed air supply.

- Pharmaceutical & Food Processing: Meeting strict process requirements with energy-efficient operation.

When combined with advanced monitoring technologies, IGCCs can operate at peak performance while minimizing the risk of costly downtime. This makes them a cornerstone of modern industrial compressor systems.

Stay ahead of equipment failures with monitoring solutions for rotating machinery, offered and supported by Clipper Controls.

Why Continuous Monitoring Is Essential for IGCCs

Integrally geared centrifugal compressors are built for efficiency and long-term reliability, but even the most robust machines are vulnerable to failure without proper oversight. Because IGCCs operate at high speeds with multiple moving components, undetected issues can quickly escalate into costly downtime, production losses, or even safety hazards.

The Cost of Unplanned Downtime

Unscheduled shutdowns can halt production lines, delay delivery schedules, and require emergency repairs. In critical industries such as petrochemicals, power generation, and pharmaceuticals, even a few hours of lost availability may cost hundreds of thousands of dollars. Beyond direct financial impact, equipment failure can jeopardize worker safety and regulatory compliance.

Condition-Based vs. Reactive Maintenance

Traditionally, many plants relied on reactive maintenance—repairing equipment after a failure occurred. Today, more facilities are adopting condition-based maintenance (CBM) strategies, enabled by continuous monitoring. CBM allows maintenance teams to address issues before they become critical, extending equipment life and reducing overall maintenance costs.

Why Monitoring Matters for IGCCs

- Early Fault Detection: Identifies developing mechanical or lubrication problems before they cause damage.

- Optimized Performance: Maintains compressors at peak efficiency by keeping critical parameters within safe ranges.

- Safety Assurance: Protects personnel and equipment from catastrophic failures.

- Predictive Maintenance Enablement: Supports long-term reliability by using data trends to forecast potential failures.

Ready to optimize your compressor monitoring strategy? Connect with our experts.

Spotlight on Metrix IGCC Solutions

Vibration Monitoring Expertise

Condition-Based Maintenance Tools

Benefits for IGCC Applications

- Early Fault Detection: Identifies small anomalies before they become major problems.

- Extended Equipment Life: Protects critical components such as bearings, seals, and gears.

- Operational Efficiency: Keeps compressors running at peak performance with fewer disruptions.

- Lower Total Cost of Ownership: Reduces maintenance spend while improving reliability.

👉 Explore Metrix condition monitoring systems through Clipper Controls, your trusted supplier for reliable industrial instrumentation.

Data Integration with Plant Control Systems

Centralized Visibility

Enabling Predictive Maintenance

By connecting compressor monitoring solutions with plant-wide control and reporting systems, facilities can optimize operations, improve reliability, and maximize return on investment.

Benefits of Compressor Monitoring

Improved Uptime and Reliability

Safer Operations

Energy Efficiency Gains

Reduced Maintenance Costs

Compliance with Safety and Regulatory Standards

Partnering for Reliable Compressor Monitoring Solutions

At Clipper Controls, we work with leading manufacturers like Metrix to deliver monitoring solutions that protect critical rotating equipment. From vibration and condition monitoring to integration with plant control systems, our expertise ensures compressors operate safely and efficiently throughout their lifecycle.

Why Work With Clipper Controls?

- Instrumentation Expertise: Decades of experience specifying sensors, transmitters, and monitoring systems for industrial applications.

- Tailored Solutions: We evaluate each facility’s needs to provide the right mix of monitoring technologies.

- Seamless Integration: Our solutions work with existing plant control systems, enhancing visibility and predictive maintenance capabilities.

Visit our product page or industry application page to learn more about how we can help your business or municipality.

Whether you are upgrading an existing compressor system, planning a new installation, or looking to strengthen your predictive maintenance program, Clipper Controls can help you specify the right solutions to improve reliability and efficiency.

Contact Clipper Controls today to specify the right IGCC monitoring solutions for your facility.

Send us a message or call us at (844) 880-2469

Page Navigation Links

- What Are Integrally Geared Centrifugal Compressors (IGCCs)?

- Why Continuous Monitoring Is Essential for IGCCs

- The Cost of Unplanned Downtime

- Condition-Based vs. Reactive Maintenance

- Why Monitoring Matters for IGCCs

- Spotlight on Metrix IGCC Solutions

- Data Integration with Plant Control Systems

- Benefits of Compressor Monitoring

- Improved Uptime and Reliability

- Safer Operations

- Energy Efficiency Gains

- Reduced Maintenance Costs

- Compliance with Safety and Regulatory Standards

- Partnering for Reliable Compressor Monitoring Solutions