Vision Inspection Systems

Vision-based instrumentation offers a powerful alternative to traditional measurement and inspection tools by providing real-time visual data from inside process vessels, pipelines, and clean-in-place systems. Clipper Controls offers advanced vision inspection systems from JM Canty, combining high-resolution imaging, integrated lighting, and robust sight glass technology to deliver precise monitoring, contamination detection, particle analysis, and process visibility across a wide range of sanitary and industrial applications.

Sight Glass

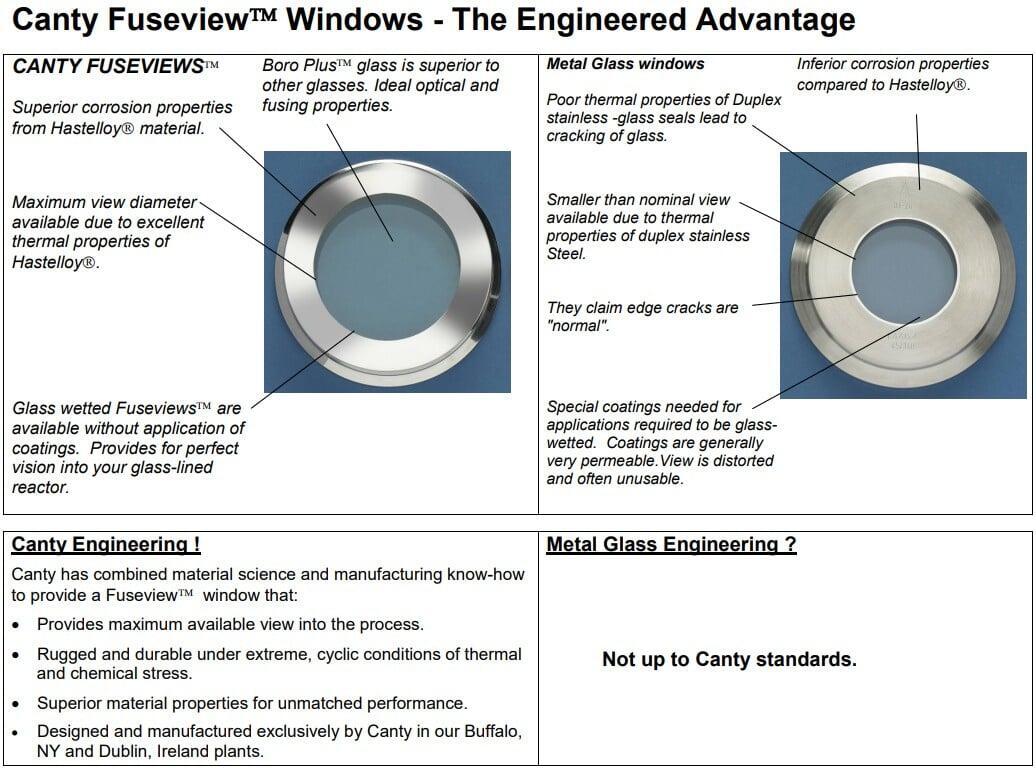

Sight glass assemblies provide critical process visibility in tanks, pipelines, and vessels, enabling operators to visually inspect fluid flow, clarity, color, and phase. JM Canty’s Boro Plus™ fused sight glass technology eliminates the need for traditional flat gaskets by a patented true fusion of borosilicate glass to the metal frame, significantly enhancing safety and long-term reliability. The use of optimum materials and a precision-controlled fusing process results in superior resistance to impact, thermal shock, and pressure, making these assemblies ideal for demanding process environments. Available in threaded, flanged, or sanitary wetted connections, they serve as high-performance replacements for conventional window and boiler sight glasses. With configurations for flat panel, round, or flush-mount designs, they are well suited for high-pressure, high-temperature, and chemically aggressive applications.

Fuseview™ Sanitary Sight Glass

The Fuseview™ Sanitary Sight Glass is engineered for hygienic processing environments requiring clean-in-place (CIP) and sterilize-in-place (SIP) compliance. Designed with a fused glass-to-metal seal, this sight glass eliminates crevices and gasket materials, making it ideal for applications where product purity and bacterial control are paramount. Offered with tri-clamp or sanitary threaded connections, it is fully CIP/SIP compatible and resistant to thermal shock and caustic washdown. Common uses include pharmaceutical reactors, bioprocess skids, dairy systems, and food-grade vessels.

Fuseview™ Industrial Sight Glass

Designed for high-pressure and high-temperature applications, the Fuseview™ Industrial Sight Glass is ideal for rugged process environments, including steam boilers, chemical reactors, and refinery lines. Its fused glass-to-metal construction withstands extreme thermal cycling and eliminates gasket blowout risk. Available in flanged and threaded models, these sight glasses meet ANSI and DIN standards and can be customized for use in ASME-rated pressure vessels. Typical applications include boiler sight ports, high-temp chemical observation points, and pressure-rated process vessels in petrochemical and power generation plants.

Fuseview™ Sight Glass Features

- Stainless, carbon, Alloy C, Hastelloy® C276 or equal, and Hastelloy® C-22® or equal fusing rings

- 150 PSI through 2500 PSI, 10 bar through 40 bar models

- Special pressures through 10,000 PSI are available

- Standard temperatures to 650°F [343°C], specials to 2000°F

- Specials available to retrofit any existing sight glass

- Quartz and Sapphire shields for caustic service

- Glass wetted models for glass lined vessels Straight or NPT threaded Fuseviews™ available

Process Lighting

Process lighting systems illuminate the interior of tanks, reactors, and pipelines, enabling clear visual inspection through sight glasses even in low-light or high-pressure environments. JM Canty process lighting integrates high-intensity, cool-running LED or halogen illumination with fused sight glass assemblies, eliminating external light fixtures and minimizing contamination risks. These lighting solutions are available in explosion-proof, sanitary, and general industrial designs to support critical process observation in cleanroom, hazardous, and corrosive environments.

Explosion Proof Sight Glass Light

The Explosion Proof Sight Glass Light is certified for Class I, Div 1 and Class II hazardous locations and designed to mount directly to fused sight glass assemblies. These lights provide intense, focused illumination inside pressurized or volatile process vessels without compromising safety. With integral power regulation and LED or halogen options, they support continuous operation in refineries, chemical plants, and flammable gas processing environments. Designed for direct mounting with no separate housing, they offer a compact and reliable lighting solution for sight ports in hazardous areas.

Sanitary Tank Light

JM Canty’s Sanitary Tank Light delivers high-output illumination through a fused sanitary sight glass, providing shadow-free, hygienic lighting for biopharmaceutical, food, and beverage processes. Designed with tri-clamp or threaded sanitary fittings, it enables clear internal visibility during CIP/SIP operations without requiring external light sources. The sealed, crevice-free construction prevents contamination while withstanding high-pressure washdown and thermal cycling. Ideal for fermenters, batch tanks, and bioreactors where aseptic integrity is critical.

Sight Glass Lights

Sight Glass Lights offer integrated lighting solutions for general-purpose industrial process observation. Mounted directly to a sight glass, these units enhance internal visibility for operators inspecting fluid clarity, phase separation, or mixing conditions. Available in various configurations—sanitary, threaded, or flanged—these lights are compatible with both fused and traditional sight glass assemblies. Applications include batch mixing, fluid transfer monitoring, and color or turbidity inspection in chemical, water treatment, and food processing systems.

Industrial Cameras

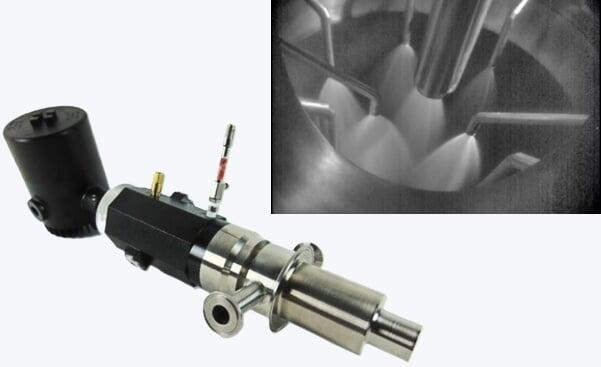

Industrial camera systems from JM Canty deliver high-resolution, real-time video monitoring for process observation, control, and quality assurance. These systems combine advanced imaging optics, integrated lighting, and fused sight glass technology to operate reliably in challenging environments including high temperature, high pressure, and sanitary conditions. Applications include particle analysis, visual inspection of mixing, fluid interfaces, foam levels, crystallization, and spray patterns, with digital outputs that support automation, remote observation, and image analysis for enhanced process control.

High Temp Camera

Biocam™ Sanitary Process Camera

The Biocam™ is a sanitary vision inspection system designed for cleanroom and sterile processing environments, where real-time visual monitoring of product quality and process behavior is essential. It features a fused sanitary sight glass and crevice-free stainless steel construction to meet stringent hygienic and aseptic standards. The Biocam™ enables direct imaging of mixing, filling, foam development, and phase separation in biopharmaceutical, food, and beverage systems. Fully CIP/SIP compatible and suited for both stainless and single-use biopharmaceutical process setups, it supports validation, batch consistency, and contamination risk mitigation without breaching sterile boundaries.

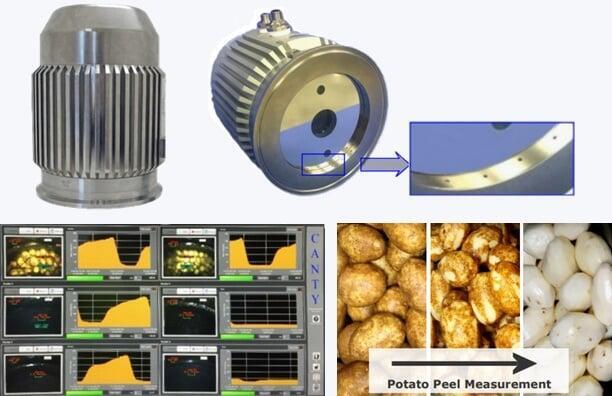

Peelercam™ Camera Vision Inspection System

Industrial Process Monitoring Camera

Particle Measuring Systems

JM Canty's particle measuring systems utilize high-resolution vision technology and advanced image processing to analyze particles in real time across a variety of media, including liquids, slurries, emulsions, and gases. Unlike traditional laser-based counters, these systems capture actual images of particles, enabling accurate sizing, shape classification, and concentration analysis. Common applications include contamination monitoring, quality control, filtration efficiency validation, and process optimization in industries such as oil refining, water treatment, pharmaceuticals, and specialty chemicals.

Oil Particle Counter

The Oil Particle Counter uses vision-based imaging to detect and classify particles suspended in petroleum-based fluids (including or excluding air bubbles and water droplets). This system delivers real-time data on particle size distribution and counts, offering a more accurate representation than traditional light-blockage or scattering devices. Ideal for hydraulic systems, lubrication loops, and fuel processing, it helps detect early signs of wear, contamination, or process deviations, supporting condition monitoring and fluid cleanliness compliance with ISO 4406 or SAE standards.

Water Particle Counter

The Water Particle Counter is designed to monitor and analyze particulate contamination in aqueous systems, including process water, ultrapure water, and wastewater. Using real-time digital imaging, the system provides detailed information on particle size, count, and morphology (including or excluding air bubbles and oil droplets). Applications include membrane integrity monitoring, water purification validation, and regulatory compliance reporting. The vision-based approach eliminates the limitations of turbidity-only measurements and enables detection of both organic and inorganic contaminants with high precision.

Solids Particle Sizing System

JM Canty’s Solids Particle Sizing System provides real-time particle size and shape analysis for dry powders, granules, and slurries using direct in-line vision inspection. It replaces manual sieving and offline laser diffraction with automated image capture and processing, reducing sampling error and improving response time. Commonly used in milling, crystallization, spray drying, and filtration systems, it helps optimize product consistency, improve yield, and reduce downtime by detecting agglomeration, fines, or off-spec product as it happens.

Vision-Based Color Measurement

Vision-Based Color Measurement systems from JM Canty evaluate color intensity and uniformity in real-time using high-resolution imaging and controlled lighting. These systems are ideal for monitoring product appearance, concentration levels, or chemical reactions in liquids, gels, and emulsions. By analyzing visible spectrum transmittance and absorbance, the system can detect process shifts and product quality deviations—making it suitable for food production, chemical blending, oil refining, and dye manufacturing applications where color is a critical quality attribute.

Need Help?

Our Crew is Here To Serve You!

Vision System Applications

Food & Beverage Processing

Spray Dryer Monitoring

Instrumentation Used:

Application Purpose:

Problem Solved / Opportunity Created:

Spray dryers are prone to nozzle clogging, misalignment, and uneven spray patterns, which can result in inconsistent particle sizes or burn-on. Vision-based monitoring systems allow operators to visually detect spray angle changes, buildup, and flow irregularities. This supports predictive maintenance, improves product uniformity, and reduces fire risk inside the dryer chamber.

Powder Particle Size Analysis

Instrumentation Used:

Application Purpose:

Problem Solved / Opportunity Created:

Traditional offline sieving methods introduce delay and sampling error. Inline vision-based particle analyzers enable real-time quality control, reducing waste and downtime while ensuring compliance with product specifications for mouthfeel, solubility, and consistency.

Fermentation Foam and Level Monitoring

Instrumentation Used:

Application Purpose:

Problem Solved / Opportunity Created:

Excess foam formation can trigger overflows, reduce fermentation efficiency, or cause contamination. Vision systems allow accurate visual monitoring without manual inspection or contact-based sensors, ensuring process continuity and hygienic control in beer, dairy, or kombucha production.

Mixing and Emulsion Monitoring

Instrumentation Used:

Application Purpose:

Problem Solved / Opportunity Created:

Improper mixing can lead to separation of ingredients, non-uniform texture, or inconsistent flavor. Vision-based instrumentation provides operators with the ability to see blend homogeneity, allowing real-time adjustments to mixing speed, time, or formulation without interrupting the batch.

Turbidity and Clarity Analysis

Instrumentation Used:

Application Purpose:

Problem Solved / Opportunity Created:

Changes in turbidity indicate potential contamination, filtration failure, or spoilage. Unlike traditional turbidity probes that may foul or require frequent calibration, vision-based systems offer non-contact, maintenance-friendly clarity measurement for quality assurance and regulatory compliance.

Fill Level and Overfill Detection

Instrumentation Used:

Problem Solved / Opportunity Created:

Overfilling can cause product loss, cleanup delays, or labeling errors. Underfilling leads to non-compliant packaging. Vision systems allow continuous fill-level validation during production runs, improving packaging efficiency and reducing product waste.

Clean-in-Place (CIP) Validation

Application Purpose:

Problem Solved / Opportunity Created:

Traditional CIP validation relies on indirect parameters like conductivity or timing. Vision-based monitoring provides direct observation to confirm whether residues or foam remain, improving food safety, reducing cleaning time, and avoiding unnecessary water or chemical use.

Pharmaceutical & Biotechnology

Crystallization Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Manual sampling and offline analysis of crystallization are time-consuming and prone to variability. Vision-based instrumentation enables continuous in-situ monitoring of crystal formation, allowing precise control of temperature and concentration parameters. This enhances batch reproducibility, reduces waste, and improves downstream filtration and drying efficiency.

Filter Dryer Cake Monitoring

Problem Solved / Opportunity Created:

Filter cake quality is critical to product recovery and drying efficiency. Vision-based systems allow operators to monitor cake integrity and endpoint drying in real time, eliminating the need to open equipment or interrupt the process. This minimizes contamination risk, improves throughput, and supports process validation.

Single-Use Bioreactor Observation

Application Purpose:

Problem Solved / Opportunity Created:

Single-use systems limit the ability to use traditional sensors due to sterility and design constraints. Vision-based instrumentation offers clear, external observation of fluid dynamics, foam development, and fill levels without breaching the sterile barrier, supporting batch consistency and real-time decision making in cell culture and fermentation.

Foam and Level Monitoring in Reactors

Instrumentation Used:

Problem Solved / Opportunity Created:

Overfilling can cause product loss, cleanup delays, or labeling errors. Underfilling leads to non-compliant packaging. Vision systems allow continuous fill-level validation during production runs, improving packaging efficiency and reducing product waste.

Emulsion and Suspension Stability Analysis

Application Purpose:

Problem Solved / Opportunity Created:

Phase separation or flocculation can affect bioavailability and dosage uniformity. Vision-based systems provide early detection of stability issues, helping researchers and manufacturers adjust formulations or mixing parameters in real time during process development and scale-up.

Clean-in-Place (CIP) and Sterilize-in-Place (SIP) Validation

Application Purpose:

Problem Solved / Opportunity Created:

Validation of CIP/SIP cycles typically relies on indirect sensor data or post-process swabbing. Vision-based instrumentation provides real-time visual assurance of cleanliness or residuals, helping to reduce cycle time, validate coverage, and improve documentation for regulatory compliance.

Particle Monitoring in Liquid Formulations

Application Purpose:

Problem Solved / Opportunity Created:

Traditional particle testing is offline and subject to batch delays. Vision-based particle counters detect and classify particulates continuously, enabling in-process quality control, supporting FDA requirements, and reducing the risk of recalls due to particulate contamination.

Oil & Gas (Exploration, Production & Refining)

Oil in Water / Water in Oil Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Phase contamination in produced water or crude oil can lead to process inefficiencies, regulatory violations, or equipment fouling. Vision-based analyzers provide a non-contact method to visually detect, size, and quantify immiscible droplets—enabling faster response than traditional capacitance or light-scattering sensors and improving separation control and discharge compliance.

Phase Interface Detection in Separators and Tank Farms

Application Purpose:

Problem Solved / Opportunity Created:

Interface levels are difficult to measure accurately with standard probes, especially in emulsions or sludges. Vision-based systems provide direct visual confirmation of phase boundaries, improving draw-off precision, reducing water carryover, and ensuring product purity during storage or transfer.

Fouling and Build-up Detection in Process Equipment

Application Purpose:

Problem Solved / Opportunity Created:

Process fouling reduces efficiency and leads to unplanned shutdowns. Vision-based monitoring enables operators to observe fouling progression without halting production or opening equipment—supporting maintenance planning and optimizing cleaning cycles.

Flare Stack and Combustion Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Unlit or unstable flares pose serious safety and compliance risks. Vision-based flare monitoring systems provide reliable detection of pilot and main flames in all lighting conditions, including bright daylight or total darkness, supporting environmental reporting and operational safety.

Fuel and Lubricant Clarity & Contamination Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Contaminants in fuel and lubricant systems can lead to injector wear, valve sticking, or turbine failure. Vision systems offer detailed, real-time insight into clarity, droplet size, or solid content—helping to ensure equipment protection, extend maintenance intervals, and support fuel quality standards.

Sand and Solids Monitoring in Produced Fluids

Application Purpose:

Problem Solved / Opportunity Created:

Sand production can erode pipelines, damage valves, and overload separation equipment. Vision instrumentation allows for real-time monitoring of solids loading and particle size distribution, enabling automated alarms and operational adjustments to mitigate equipment damage and optimize production rates.

Mining & Aggregate

Slurry Particle Size Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Traditional sampling and laboratory analysis delay feedback and can misrepresent process variability. Vision-based systems provide real-time particle size distribution, helping optimize grinding circuits, improve recovery rates, and reduce reagent use in flotation and leaching operations.

Tailings Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Uncontrolled tailings can impact environmental compliance and downstream water recovery. Vision-based instrumentation enables continuous, visual evaluation of solids content, helping optimize thickener performance, detect underflow anomalies, and support water reclamation efficiency.

Froth Flotation Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Froth appearance reflects reagent dosage, gas flow, and hydrodynamics. Vision-based tools allow automated detection of bubble size, froth height, and texture, supporting consistent concentrate grade and improving operator response to process fluctuations.

Turbidity and Clarification Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Clear water recovery is essential for recycling and environmental discharge. Vision instrumentation provides continuous, non-contact measurement of suspended solids, offering faster response than turbidity probes and eliminating sensor fouling in abrasive slurries.

Crushing and Screening Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Undetected screen blinding or crusher wear can lead to off-spec product and equipment damage. Vision-based systems allow operators to visually confirm material condition and flow rate, enabling timely intervention and maximizing uptime.

Conveyor Belt Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Misaligned belts and material losses lead to operational inefficiencies. Vision instrumentation allows continuous observation of belt integrity, material trajectory, and loading balance, supporting preventative maintenance and improving safety.

Dry Powder Particle Analysis

Application Purpose:

Problem Solved / Opportunity Created:

Sieve-based analysis is labor-intensive and inconsistent. Vision-based particle analyzers offer fast, objective, and repeatable particle classification for process verification and product certification.

Conveyor Belt Monitoring

Application Purpose:

Problem Solved / Opportunity Created:

Misaligned belts and material losses lead to operational inefficiencies. Vision instrumentation allows continuous observation of belt integrity, material trajectory, and loading balance, supporting preventative maintenance and improving safety.

Terms & Definitions

- Agglomerate Detection

- Identification of particle clumping or agglomeration that may affect product consistency or flowability.

- Backscatter Imaging

- Use of reflected light in vision systems to analyze turbidity or particle concentration in opaque media.

- Batch Observation

- Real-time imaging of batch processes to visually verify mixing, heating, or separation behavior.

- Boiler Sight Port Monitoring

- Use of high-temp vision cameras to inspect combustion and flame conditions in steam boilers.

- Build-Up Detection

- Visual identification of product accumulation on process surfaces such as spray nozzles, dryer walls, or reactor internals.

- Centrifuge Monitoring

- Imaging of separation processes inside centrifuges to verify phase cut, cake ejection, and balance.

- Color Uniformity Inspection

- Vision-based measurement of product color to ensure consistency in blends, dyes, or finished goods.

- Combustion Monitoring

- Visual inspection of flame presence, shape, and color to verify burner performance and safety.

- Crystallization Monitoring

- Real-time visualization of crystal formation to control nucleation, growth rate, and final product morphology.

- Dryer Optimization

- Use of vision systems in spray or rotary dryers to monitor drying progression and detect buildup or nozzle failure.

- Emulsion Observation

- Real-time visualization of emulsion stability and interface formation to optimize blending and formulation.

- Fill Level Inspection

- Non-contact verification of fluid or solid levels in bottles, vials, or tanks during production.

- Filter Breakthrough Detection

- Imaging-based detection of turbidity changes indicating filter media failure or bypass.

- Filter Dryer Cake Monitoring

- Imaging of solid cake layers inside filter dryers to assess dryness, cracking, or flowability without opening the equipment.

- Flare Monitoring

- Remote visual confirmation of flame presence, stability, and combustion quality in flare stacks.

- Flash Zone Observation

- Use of explosion-proof vision systems to observe high-pressure, high-temp flashing processes in refining.

- Fluid Interface Tracking

- Visual tracking of liquid-liquid or liquid-gas interfaces to optimize draw-off and prevent mixing.

- Foam Detection

- Continuous observation of foam height and stability in bioreactors or fermentation tanks to prevent overflows and process disruption.

- Foam Stability Analysis

- Monitoring of foam collapse rate and formation dynamics in bioreactors and fermentation vessels.

- Froth Monitoring

- Measurement and analysis of froth in flotation cells to improve mineral recovery and reagent control.

- Interface Detection

- Visual identification of phase boundaries in separators or tanks, such as oil-water or oil-gas interfaces.

- Mixing Visualization

- Observation of mixing patterns to ensure uniform blending and prevent dead zones in process tanks.

- Multiphase Flow Inspection

- Imaging of simultaneous flow of solids, liquids, and gases to assess phase distribution and flow behavior.

- Nozzle Clog Detection

- Real-time visual verification of spray nozzle obstruction or misalignment.

- Opacity Analysis

- Measurement of light blockage through a medium to infer particulate or phase concentration.

- Optical Flow Cell

- A transparent chamber used with vision systems for continuous imaging of flowing media.

- Particle Analysis

- Imaging-based sizing and shape classification of solid particles in liquids, powders, or slurries.

- Phase Separation Monitoring

- Observation of stratification or mixing between immiscible process phases for separation efficiency or stability.

- Process Light Integration

- Combining vessel lights with cameras for shadow-free illumination and improved image clarity.

- Process Observation

- Visual inspection of internal vessel conditions such as mixing, flow patterns, color changes, or level via integrated camera systems.

- Reactor Visualization

- In-situ imaging of chemical reactors to monitor reactions, agitation, or coating.

- Real-Time Image Processing

- Automated interpretation of video data to extract measurements, alarms, or trends.

- Sanitary Vision Inspection

- Hygienically designed imaging systems used in cleanroom or CIP/SIP environments for monitoring sterile processes.

- Sight Glass

- A transparent viewing port, often fused to metal, used to inspect fluid levels or conditions within a vessel or pipeline.

- Single-Use Monitoring

- External vision systems for observing conditions inside single-use bioreactor bags or disposable systems without breaching sterility.

- Slurry Monitoring

- Real-time imaging of solid-liquid mixtures to evaluate particle concentration and behavior in mining, milling, or chemical processes.

- Spray Pattern Analysis

- Inspection of atomized fluid sprays to detect clogging, misalignment, or drift in spray dryers, burners, or coating systems.

- Tote & Tank Inspection

- Vision monitoring of portable tanks or IBCs for level, clarity, or contamination.

- Turbidity Measurement

- Vision-based assessment of fluid clarity using transmitted or scattered light to evaluate contamination or filtration performance.

- Vessel Lighting

- Explosion-proof or sanitary lights mounted to sight glasses or ports to illuminate process interiors for observation or imaging.

- Vision-Based Instrumentation

- Imaging systems integrated with lighting and optics used to monitor, analyze, and control industrial processes through visual data.

- Visual Level Monitoring

- Camera-based determination of liquid height in tanks or vessels, often used where radar or float sensors are impractical.

- Water/Oil Quality Analysis

- Detection of immiscible droplets or particulate contamination in fuel, lubricants, or produced water using visual classification techniques.