Fiberglass (FRP) Shelters

Protection for Instrumentation, Analyzers, and Controls in Harsh Environments

Fiberglass‑reinforced plastic (FRP) shelters provide durable, low‑maintenance protection for equipment exposed to weather, chemicals, and coastal or high‑UV conditions. Compared to metal enclosures, FRP resists corrosion, won’t dent or rust, and offers excellent thermal performance—helping your pressure, flow, and analytical systems operate reliably year‑round.

👉 Send us a message or call us at (880) 844-2469 even if you are at an early stage of researching shelters. We are an excellent resource and will be happy to help you explore options and qualify features.

Explore related pages: Equipment Shelters, Fiberglass Metering Manholes, Analyzers, Water Samplers, Flow Meters, Signal Interface

Contact us for application assistance!

Why Fiberglass Shelters

- Corrosion resistance: FRP construction tolerates salt air, chlorinated water, and many chemicals.

- UV stability & weatherability: Gel‑coat finishes and resins hold up to sun, rain, and freeze/thaw cycles.

- Lightweight & strong: Easier to crane into remote sites with high wind/snow load options available.

- Thermal efficiency: Insulated wall/roof panels reduce HVAC demand and protect sensitive instruments.

- Lower lifecycle cost: Minimal repainting or galvanic maintenance vs. metal structures.

Typical Applications

- Water & Wastewater: Chemical feed skids, sampling/analyzer shelters, pump and blower controls, filter backwash panels.

- Power Generation: Draft/stack monitoring shelters, CEMS/analyzer houses, cooling water treatment.

- Mining & Minerals: Slurry metering, remote pump stations, tailings monitoring and communications panels.

- Chemical Processing: Storage tank level/transfer controls, scrubber instrumentation, corrosion‑prone areas.

- Remote Telemetry/RTU: SCADA nodes, solar/battery systems, and network equipment.

👉 Talk with the Clipper Controls Service Team about integrating shelters with Instrumentation, Controls, or Analytical Equipment.

Construction & Standard Features

- FRP panel system: Rigid, corrosion‑resistant composite walls and roof with smooth gel‑coat exterior.

- Insulation: Options for wall/roof R‑values suited to your temperature range.

- Roof design: One‑piece roof with drip edges; skylight or translucent panels optional.

- Door assembly: Insulated FRP door(s) with full perimeter gasket, stainless hinges, and lockset; clear openings sized for equipment access.

- Base & floor: FRP or skid base; option for non‑conductive floor, grated sump, or raised thresholds.

- Hardware: Stainless steel fasteners and exterior fittings to resist corrosion.

- Cable entries: Sealed gland plates/conduit hubs; interior back‑paneling for instruments and junction boxes.

- Lighting & power pre‑wire (optional): LED fixtures, receptacles, GFCI, and interior raceways.

👉 Have a feature question or a unique/specialized need? Call us at: (844) 880-2469

Environmental Control Options

- HVAC: Packaged AC/heat, heater‑only, or ventilation fans sized for your heat load.

- Filtration & purge: Inlet filters, dust hoods, and positive‑pressure purge/pressurization where required.

- Sunshades & coatings: Exterior sun shields and high‑reflectance finishes for desert or coastal sites.

- Hazard‑area options: Components available to align with site hazardous‑location requirements (when specified).

- Monitoring: Thermostats, high‑temp/door alarms, and light status indications to SCADA.

Sizing & Specification Guide

- Shelter size & clearances for equipment footprint, maintenance aisle, and door swing.

- Design loads: Wind, snow, and seismic per local requirements.

- Thermal design: Insulation R‑value and HVAC capacity for ambient extremes.

- Chemical exposure: Resin/gel‑coat selection and hardware metallurgy.

- Electrical service: Voltage, panelboard layout, receptacles, lighting, and convenience power.

- Penetrations & routing: Conduit stubs, cable trays, floor sumps, and roof penetrations.

- Safety & access: Non‑slip floor, eyewash/shower adjacency (if required), and ADA/site access.

Get a personalized specification matched to your equipment list, power, and environmental conditions.

Integration & Fit‑Out by Clipper Controls

- Instrument backpanels, marshalling/termination, field cable labeling, and numbered wire schemes tied to as‑built drawings and panel schedules.

- Mounting and piping for transmitters, analyzers, chemical feed pumps, and sample conditioning systems (heat‑traced and insulated where required), with drip trays and isolation valves.

- Lighting, receptacles, panelboards/UPS, and network gear (managed switches, LTE/CBRS gateways) with documented I/O lists, wiring diagrams, and network addressing.

- HART®/Modbus integration to existing PLC/SCADA with templates, register maps, preloaded device tags, square‑root/scaling, and loop checks captured in the turnover package.

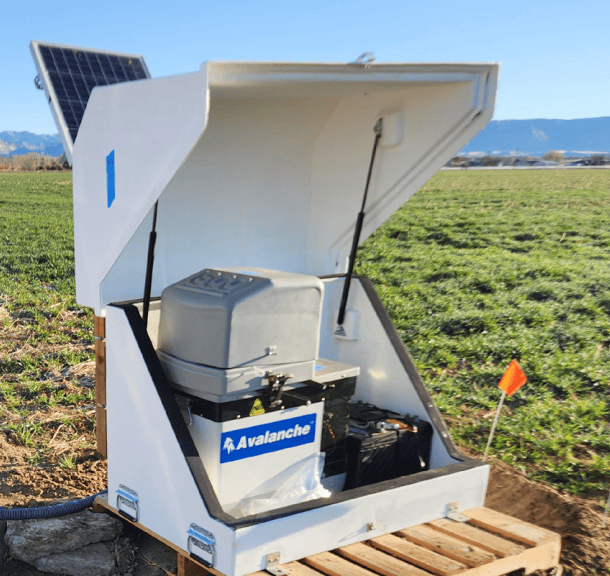

- Solar power options for remote sites: roof‑ or pole‑mounted PV arrays, MPPT charge controllers, AGM or LiFePO₄ battery banks, DC distribution, and inverters sized from a site‑specific load/insolation study; optional telemetry for state‑of‑charge and alarms.

- Penetrations, glands, RF pass‑throughs, and antenna mounts for radios or cellular; pre‑terminated external connection stubs to speed field hookup.

- FAT/SAT support with as‑built drawings, single‑line and wiring diagrams, labeling, and installation guides; optional on‑site startup and operator training.

Delivery & Installation Support

- Foundation: Guidance for slab, piers, or skid anchoring; anchor kits available.

- Lift & placement: Lifting eyes and spreader bar recommendations; on‑site alignment.

- Sealing: Base flashing, weatherproof penetrations, and drainage details.

- Startup: HVAC function checks, power‑up verification, and documentation handoff.

👉 Request a quote with lead time and shipping details.

Work with Clipper Controls