Industrial Gas Detectors

Continuous Toxic & Combustible Gas Monitoring for Safer Facilities

👉 Schedule a free on-site consultation with Clipper Controls to discuss gas detection in your facility.

Need service for your gas detector? Message our Service Team or call us at (844) 880-2469.

Explore related pages: Gas, Flame & Leak Detectors, Calibration Service, Field Services, Analyzers, Equipment Shelters, Process Control Applications

Contact us for application assistance!

Why Industrial Gas Detection Matters

Industrial gas detectors:

- Provide continuous monitoring in areas where leaks are most likely.

- Trigger local audible/visual alarms and send signals to PLC/SCADA systems.

- Support automatic shutdowns or ventilation startup to reduce risk.

- Help satisfy regulatory and insurance requirements for hazardous locations.

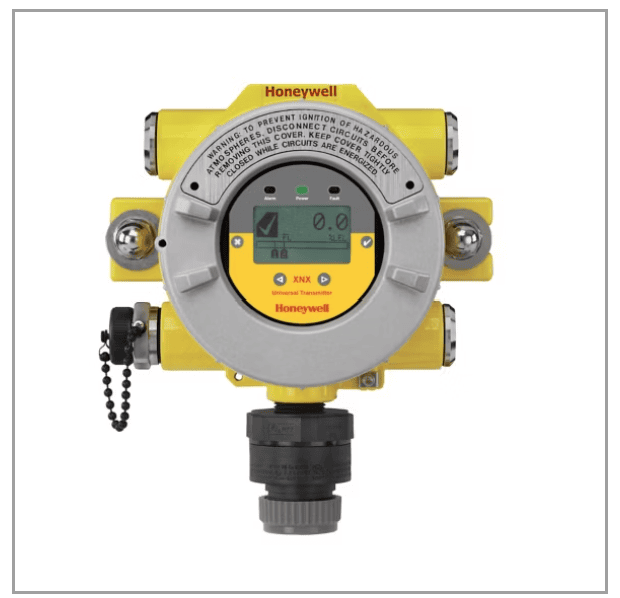

Honeywell Industrial Gas Detector Types

Fixed Point Gas Detectors

Honeywell’s fixed platforms support:

- Combustible gas (LEL) monitoring using catalytic bead or infrared sensors.

- Toxic gas detection (e.g., H₂S, CO, NH₃, Cl₂, NO₂) with electrochemical sensors.

- Oxygen deficiency/enrichment monitoring in inerting or CO₂-enriched areas.

- Boiler, furnace, and mechanical rooms

- Compressor buildings and generator rooms

- Chemical process units and loading racks

- Pump stations, treatment buildings, and analyzer shelters

Open-Path Infrared Gas Detectors

- Tank farms and loading/unloading terminals

- Pipe racks and manifolds

- Compressor stations and gas turbine inlets

- Outdoor production units and LNG facilities

Portable & Confined Space Gas Detectors

- Single-gas options for H₂S, CO, O₂, and other toxic gases.

- Multi-gas detectors for LEL, O₂, CO, H₂S and additional toxic sensors.

- Compact, rugged housings designed for belt or harness wear.

- Docking stations for bump testing, calibration, and recordkeeping.

- Confined space entry (tanks, pits, vaults, sumps)

- Maintenance rounds and leak investigation

- Turnarounds and temporary work areas

Wireless & Temporary Gas Detection

- Turnarounds and construction zones

- Remote or temporary equipment (skid-mounted units)

- Expanding coverage without adding new cable trays or conduits

👉 Talk with the Clipper Controls Service Team about integrating industrial gas detectors at your facility.

Key Industrial Applications

Refining & Chemical Processing

- Toxic gas monitoring for H₂S, NH₃, Cl₂, CO, and other process gases

- Combustible gas and LEL monitoring around process units and loading racks

- Open-path hydrocarbon detection across tank dikes and manifolds

Energy & Power Generation

- Gas turbines, boiler rooms, and fuel gas skids

- Generator rooms and enclosed machinery spaces

- CEMS shelters and stack monitoring support systems

Water, Wastewater, and Food Processing

- Chlorine, ozone, and ammonia storage and feed rooms

- Anaerobic digesters and biogas handling systems

- Refrigeration plants (ammonia and CO₂ leak detection)

Mining & Aggregates

- Underground or enclosed equipment bays and pump stations

- Fuel storage and transfer areas

- Remote shelters for analyzers and controls

Talk with Clipper Controls about gas detection strategies for your specific industry and site layout.

👉 Call us at: (844) 880-2469

Integration, Calibration & Services from Clipper Controls

System design & placement

- Review process hazards, gas types, densities, and ventilation patterns

- Recommend detector locations, mounting heights, and technologies (point vs. open-path vs. portable)

- Coordinate with fire & gas panels, PLC/SCADA, and ESD systems

Panel and network integration

- Interface Honeywell detectors via 4–20 mA, relays, HART, and Modbus into existing or new safety systems

- Provide recommended alarm setpoints, voting logic, and cause-and-effect matrices

Commissioning and training

- On-site startup assistance, bump testing, and functional checks

- Operator and maintenance training on daily use, bump test routines, and alarm response

Calibration & ongoing support

- Scheduled calibration services for gas detectors—on-site or via return/factory channels

- Assistance with sensor replacement intervals, span gas selection, and recordkeeping for audits

Work with Clipper Controls

Page Navigation Links

- Why Industrial Gas Detection Matters

- Honeywell Industrial Gas Detector Types

- Fixed Point Gas Detectors

- Open-Path Infrared Gas Detectors

- Portable & Confined Space Gas Detectors

- Wireless & Temporary Gas Detection

- Key Industrial Applications

- Refining & Chemical Processing

- Energy & Power Generation

- Water, Wastewater, and Food Processing

- Mining & Aggregates

- Integration, Calibration & Services from Clipper Controls

- System design & placement

- Panel and network integration

- Commissioning and training

- Calibration & ongoing support

- Work with Clipper Controls

Click to learn more about other Gas, Leak, and Flame Detectors we offer.