How to Choose the Right Sight Glass

Sight Glass for Industrial Process Monitoring

Tip for Engineers: When specifying a sight glass, consider the full system environment—pressure, temperature, chemical compatibility, and cleaning requirements—to ensure reliable long-term performance.

👉 Schedule a consultation with Clipper Controls to learn more about our premium lineup of industrial sight glass products.

Key Factors in Sight Glass Selection

Choosing the right sight glass starts with understanding the operating environment. The key considerations—pressure, temperature, chemical compatibility, and optical performance—determine both safety and longevity. Each factor affects not only the glass itself but also the housing, seals, and overall installation.

Pressure and Temperature Ratings

Every sight glass window must withstand the internal forces of the process system. Pressure ratings should match or exceed system design limits, especially in high-pressure or cyclic applications. Thermal shock resistance is equally important, as rapid temperature changes can stress the glass and compromise sealing surfaces.

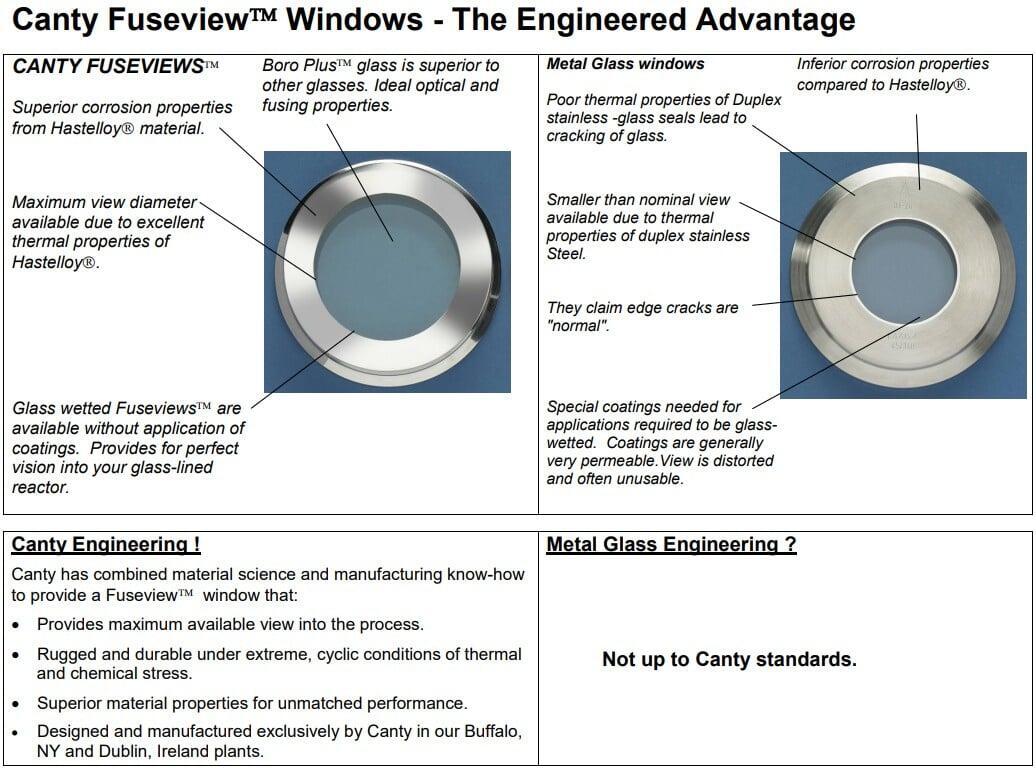

Fused-glass sight windows, such as those engineered by JM Canty, are designed to handle these demanding conditions. By fusing the glass directly to the metal body, these assemblies eliminate gasket interfaces, reducing the risk of leaks and mechanical failure under extreme pressure and temperature.

Chemical Compatibility and Housing Materials

Chemical resistance ensures that both the glass and the metal housing maintain integrity over time.

Stainless steel housings offer a balance of strength and corrosion resistance for general-purpose use.

Hastelloy sight glass assemblies are preferred for highly corrosive environments, such as acid gas scrubbing, caustic chemical processing, or chlorine handling.

Material compatibility extends to gaskets and bonding materials—these must also resist degradation to maintain a secure, long-lasting seal. Choosing compatible materials helps prevent pitting, fogging, or etching that can reduce optical clarity and shorten service life.

Optical Clarity and Application Type

Not all sight glass applications demand the same level of visibility. Some systems require clear visual inspection of flow or foam, while others focus on verifying fluid color or detecting phase separation.

For applications where lighting is limited or media opacity is high, integrating process observation sight windows with illumination or camera systems can dramatically improve visibility. These enhanced assemblies are particularly beneficial for pharmaceutical or food & beverage processes, where visual inspection ensures consistent quality and batch integrity.

👉 Enhance process visibility with engineered sight glass assemblies — contact Clipper Controls.

Sight Glass Material Comparison: Borosilicate vs. Quartz vs. Sapphire

Selecting the proper sight glass material is essential for achieving reliable, distortion-free visibility and long service life. Each glass type offers unique properties in terms of temperature tolerance, mechanical strength, and chemical resistance. The choice depends on the process environment and the type of monitoring required.

Borosilicate Sight Glass: The Industry Standard

Borosilicate glass is the most common choice for industrial sight glasses thanks to its balance of strength, thermal resistance, and affordability. It performs well in moderate-pressure and temperature applications, making it ideal for general-purpose use in water treatment, food and beverage, and basic chemical processes.

Temperature range: up to ~500 °F (260 °C)

Good resistance to thermal shock and most neutral chemicals

Cost-effective and widely available

However, borosilicate’s mechanical strength is limited compared to quartz or sapphire, so it may not be suitable for high-pressure or abrasive environments.

Quartz Sight Glass: Higher Purity and Thermal Stability

Quartz glass offers superior thermal and chemical stability, making it the preferred option when processes involve high temperatures or aggressive media. It maintains optical clarity under repeated sterilization or CIP/SIP cycles and resists clouding over time.

Temperature range: up to ~1000 °F (540 °C)

Excellent UV and IR transmission

Resistant to acids and oxidizers

Sapphire Sight Glass: Maximum Strength and Scratch Resistance

For the most demanding environments, sapphire sight glass delivers unmatched durability. With hardness second only to diamond, sapphire resists scratching, impact, and abrasion—even under high-velocity flow or particle-laden conditions. Its exceptional pressure rating and optical clarity make it ideal for high-pressure reactors, abrasive slurries, and chemical process monitoring.

Pressure capability: up to 20,000 psi (depending on assembly design)

Temperature range: up to ~1500 °F (815 °C)

Exceptional resistance to mechanical wear and corrosive attack

👉 Contact Clipper Controls to specify the best glass material for your process visibility needs.

The Advantage of Fused-Glass Sight Windows

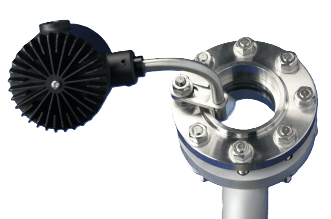

Traditional sight glasses rely on mechanical gaskets and seals to hold the glass in place. Over time, these seals can deteriorate under thermal cycling, pressure fluctuations, or chemical attack—creating potential leak paths and safety risks. Fused-glass sight windows, pioneered by JM Canty, solve this problem by permanently bonding the glass to the metal housing, forming a single, monolithic assembly that is stronger, safer, and maintenance-free.

Leak-Free Integrity and Long-Term Durability

In a fused-glass design, the glass is metallurgically sealed to the housing during manufacturing. This eliminates the need for gaskets, clamps, or retaining rings that can loosen or degrade over time. The result is a sight window with exceptional pressure resistance and a virtually leak-proof seal, ideal for high-pressure and hazardous process environments.high-pressure and hazardous process environments.

Fused-glass assemblies maintain integrity through repeated sterilization, vibration, and temperature cycling—conditions that often challenge conventional bolted windows. For operators, that translates to less downtime, fewer maintenance intervals, and a safer overall system.

Enhanced Optical Performance and Visibility

Because the glass and metal form a single, continuous structure, optical distortion is minimized. JM Canty’s fused-glass windows offer crystal-clear, true-color viewing of process media, allowing operators to accurately assess fluid clarity, foam formation, or emulsion stability. When combined with integrated lighting and imaging systems, they enable continuous process observation—even in dark, high-pressure, or opaque media environments.crystal-clear, true-color viewing of process media, allowing operators to accurately assess fluid clarity, foam formation, or emulsion stability. When combined with integrated lighting and imaging systems, they enable continuous process observation—even in dark, high-pressure, or opaque media environments.

These systems are especially valuable in mixing, emulsion, and phase change monitoring applications, where real-time visual feedback ensures process consistency and quality control.

Maintenance and Safety Benefits

No gaskets or O-rings to replace, reducing leak risk and maintenance costs

High pressure and temperature ratings, exceeding ASME and DIN standards

Long service life, even in abrasive or corrosive conditions

Available with sanitary and hygienic fittings for food, beverage, and pharmaceutical processes

By combining optical performance with mechanical strength, fused-glass sight windows deliver unmatched reliability for continuous process observation.

👉 Contact Clipper Controls and upgrade to gasket-free, leak-proof sight windows engineered for modern process environments.

Applications Across Process Industries

Chemical Processing

- Reactor vessel monitoring

- Acid and caustic feed line observation

- Phase interface verification in separators and scrubbers

Pharmaceutical Manufacturing

- Fermenter and bioreactor observation

- Crystallizer and centrifuge inspection

- Quality verification during liquid formulation

Food and Beverage Production

- Mix tank and blending vessel observation

- Foam and aeration monitoring in beverage lines

- CIP cycle verification and fluid level monitoring

👉 Explore sight glass and process camera systems tailored to your industry with Clipper Controls.

Enhancing Process Visibility and Safety

In today’s industrial environments, the ability to see the process in action is more than a convenience—it’s a safety and productivity imperative. Process observation sight windows, when combined with advanced lighting and camera systems, enable continuous visual verification of operations that once relied on intermittent manual checks.

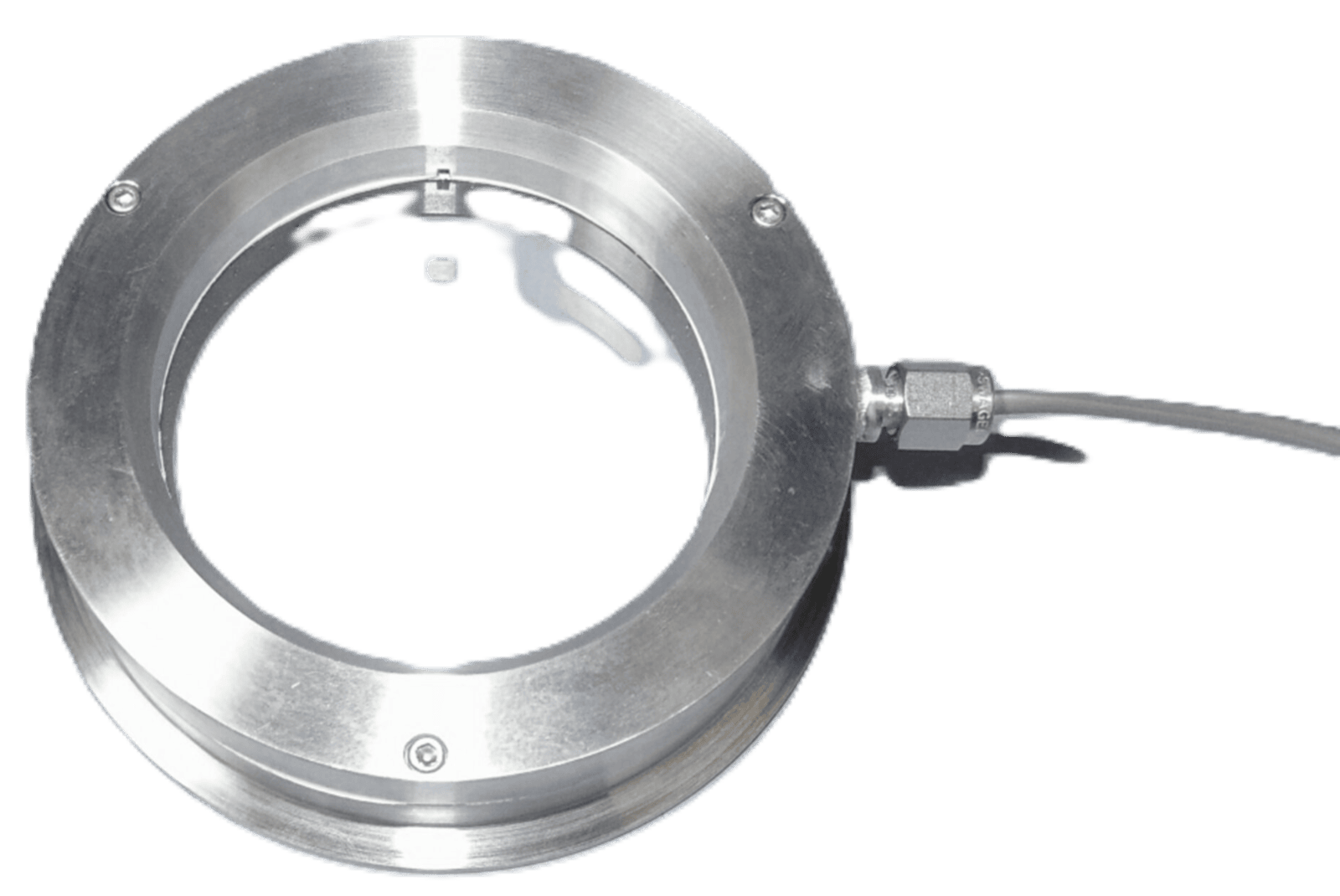

Integrating Jet Spray Rings

Integrating Lighting and Imaging Systems

A sight glass provides the window, but without proper illumination, even the clearest material can limit visibility. JM Canty’s fused-glass sight windows and process cameras integrate specialized lighting systems that deliver bright, shadow-free visibility directly into process vessels or pipelines.

- Detect emulsions, foam formation, and phase boundaries in real time

- Verify mixing uniformity and flow characteristics

- Observe crystallization, precipitation, or separation as they occur

Partnering with Clipper Controls for Sight Glass Solutions

👉 Work with Clipper Controls to select the right sight glass window for your specific process conditions.

Contact Clipper Controls for your sight glass window needs by calling (844) 880-2469, or send us a message using our website form.