Sewer Flow Meter Solutions for Wastewater & Collection Systems

👉 Whether you’re planning an I&I study, monitoring an industrial sewer discharge, or upgrading legacy open-channel meters, we can help you specify a sewer flow monitoring system that’s built for real-world wastewater conditions. Contact us today!

Similar Pages: Water & Wastewater Industry Process Control Applications | Flow Instrumentation | Metering Manholes | Automatic Water Samplers

What Is a Sewer Flow Meter and Why it Matters

- Level measurement – to determine depth in the pipe or manhole

- Velocity measurement – using area-velocity (AV) or non-contact Doppler/laser methods

- Data logging and communications – to trend, alarm, and report flow for engineering studies and compliance

Open-Channel Sewer Flow Measurement: Depth, Velocity, and AV

- The meter measures depth, then calculates the cross-sectional area of the pipe or channel.

- It measures velocity using an AV sensor or non-contact technology.

- It computes flow rate and integrates over time to provide totalized volume.

- Area-velocity meters with submerged AV sensors

- Non-contact sewer flow meters using laser or ultrasonic methods

- Level + primary device (flumes/weirs) where hydraulic conditions allow

Teledyne ISCO Sewer Flow Meter Lineup

Signature Flow Meter for Permanent Sewer Discharge Monitoring

- Supports area-velocity, non-contact LaserFlow, and other flow measurement methods

- Multiple sensor inputs for redundant level/velocity or combining flow with sampler control

- Built-in data logging with detailed event and totalized flow records

- Integration with SCADA, PLCs, and telemetry using common industrial protocols

- Industrial sewer discharge monitoring for pretreatment compliance and cost allocation

- Wastewater treatment plant influent/effluent flow verification

- Permanent trunk line and interceptor monitoring stations

DuraTracker for Long-Term Sewer Flow Studies and I&I Projects

- Flexible inputs for AV sensors, level sensors, and LaserFlow

- Optimized for low-power, battery-based operation

- Advanced data logging for multi-month deployments

- Rugged housing designed for harsh sewer environments

- Inflow & infiltration (I&I) studies across multiple basins

- Temporary or semi-permanent sewer flow monitoring for capacity modeling

- CSO/SSO project data collection

LaserFlow Non-Contact Sensor for Manholes and Difficult Sites

- Non-contact design keeps critical components out of the sewage stream

- Ideal for manholes, surcharged lines, and low-slope sewers

- Pairs with Signature or DuraTracker to form a complete open-channel sewer flow meter system

- Optional redundant submerged AV sensor for backup during submerged conditions

AV and Level Sensors for Partially Full Pipes

- Submerged AV sensors measure both velocity and depth in partially full pipes

- Ultrasonic or bubbler level sensors monitor depth over primary devices or in manholes

- Sensors integrate directly with Signature and DuraTracker for compact, easy-to-service systems

- Standard sanitary sewer mains

- Sewers with moderate solids where scheduled maintenance is acceptable

- Sites with existing flumes, weirs, or other primary devices

Power, Enclosures, and Telemetry for Remote Sewer Flow Monitoring

Beyond the instrument itself, sewer flow meters depend on reliable power, protection, and data paths. A sewage flow meter is only as useful as the data you can retrieve. Teledyne ISCO systems offer flexible options to keep instruments powered and connected in remote sewer locations.

Power options:

- Internal battery-powered sewer flow meter deployments for long-term logging

- External 12–28 VDC power where site power is available

- Solar-assisted systems for extended deployments with telemetry

Enclosures and mounting hardware:

- NEMA-rated enclosures for above-ground or roadside cabinets

- Pipe, wall, and bridge mounting hardware kits

- Manhole deployment hardware for LaserFlow and submerged AV sensors

Telemetry & data retrieval:

- Cellular or radio telemetry for distributed networks

- Direct SCADA/PLC integration from Signature at permanent stations

- Onboard data logging with removable storage for manual data collection

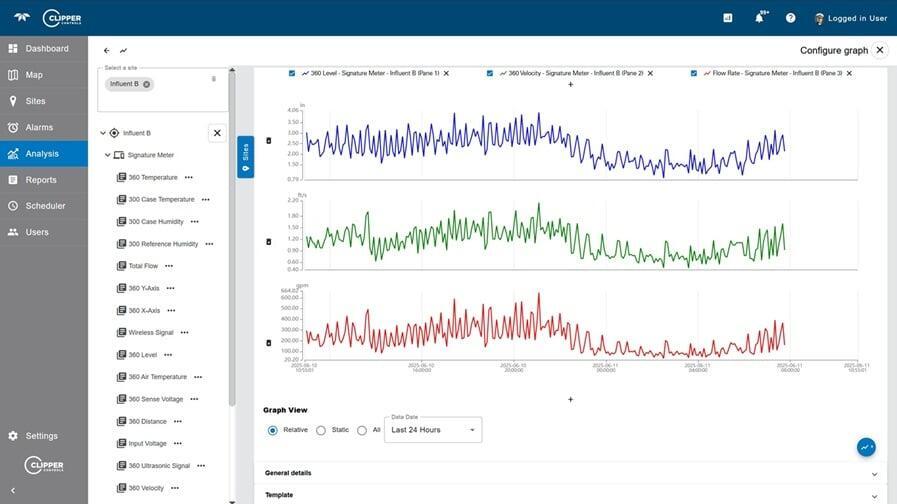

- For long-term trending and dashboards, ClipperView Flow Monitoring Software can visualize data from distributed sewer flow meters.

Where Sewer Flow Meters Are Used

I&I and Sewer Capacity Studies

- Monitor nighttime minimum flows to identify groundwater infiltration

- Track wet-weather response to pinpoint inflow problem areas

- Generate the depth and flow data required by hydraulic models and consultants

Industrial Sewer Discharge and Pretreatment Monitoring

- Provide continuous flow totals for billing and surcharge calculations

- Tie into composite samplers for flow-weighted sampling

- Integrate with plant SCADA for real-time monitoring and alarms

Storm, Combined, and Sanitary Sewer Networks

- Sanitary sewers for routine monitoring and capacity planning

- Combined sewer systems to track overflow risk and regulatory compliance

- Storm sewers and outfalls where flow data supports permit reporting

How Clipper Controls Helps Specify the Right Sewer Flow Meter

- Select the right platform (Signature vs. DuraTracker) for each site

- Decide between non-contact LaserFlow and submerged AV sensors

- Configure level-only vs. full area-velocity measurement

- Size power systems (battery, solar, or external supply)

- Plan telemetry and data retrieval to match your SCADA/IT standards

- Specify enclosures, mounts, and accessories for safe, serviceable installations

👉 Ready to talk through a sewer flow meter project?

FAQ

A sewer flow meter is an instrument designed to measure flow rate and totalized volume in gravity sewers and open-channel wastewater systems. It typically combines level and velocity measurement (or level plus a primary device like a flume) to calculate flow in partially full pipes.

- Area-velocity measurement – A submerged AV sensor measures both depth and velocity; the meter uses pipe geometry to calculate flow.

- Non-contact measurement – A LaserFlow non-contact sewer flow meter measures velocity below the surface while also measuring level from above.

- Level + primary device – In some structures, flow is derived from ultrasonic level over a flume or weir.

- DuraTracker as the flow meter and data logger

- LaserFlow for non-contact measurement where debris and surcharge are concerns

- Submerged AV sensors where installation conditions favor direct in-stream measurement

- Battery-powered setups with optional telemetry for remote access

- There is heavy debris, grease, or ragging in the line

- Access is primarily from the surface through a manhole

- You want to minimize confined-space entries and cleaning trips

- The site experiences surcharged or highly variable depth conditions

- Common industrial communication protocols

- Interfaces for cellular or radio telemetry

- Onboard data logging with downloadable records for engineering analysis

👉 Need help specifying a sewer flow meter in CA, NV, or HI?

Page Navigation Links

- What Is a Sewer Flow Meter and Why it Matters

- Open-Channel Sewer Flow Measurement: Depth, Velocity, and AV

- Teledyne ISCO Sewer Flow Meter Lineup

- Power, Enclosures, and Telemetry for Remote Sewer Flow Monitoring

- Where Sewer Flow Meters Are Used

- How Clipper Controls Helps Specify the Right Sewer Flow Meter

- FAQ