CNG Custody Transfer Tracking & Data Management

- Custody-grade CNG flow measurement

- Proper pressure and temperature compensation

- Robust flow conditioning

- PLC/HMI-based tracking and batching

- Clean signal handoff to SCADA and business systems

👉 Talk to a CNG custody transfer specialist about your metering run, tracking requirements, and audit-ready data trail.

Explore Similar Pages: Flow Instrumentation Products for Liquid & Gas | Flare Gas Meters & Flare Solutions | Oil & Gas Pipeline Process Control Applications | Types of Mass Flow Meters: Choosing the Right Technology | Kurz Instruments – Thermal Mass Flow Meters for Gas Measurement | Ultrasonic Sound Speeds in Solids and Liquids (Application Note)

Where CNG custody transfer happens

- CNG is transferred from producers to midstream operators

- CNG is loaded into trailers or tube skids for over-the-road delivery

- CNG is delivered to industrial end users or satellite stations

- Accurate primary measurement of CNG flow, pressure, and temperature

- Consistent, documented corrections to standard conditions

- Traceable totals that match invoices and contracts

- Signal ownership and integrity when multiple stakeholders rely on the same measurements

Why CNG projects are moving from turbine to ultrasonic

- No moving parts – no turbine blades to wear, foul, or stick

- Low pressure drop – preserving valuable pressure across the metering run

- Deep diagnostics – multipath data provides insight into profile, fouling, and meter health

Measurement layer: CNG custody transfer starts at the meter run

Custody-grade CNG flow measurement – Panametrics Sentinel

- Multipath ultrasonic measurement for high-accuracy CNG flow

- Averaging of the velocity profile to handle real-world piping effects

- Built-in diagnostics to monitor signal strength, profile asymmetry, and meter health

- Digital outputs and communications for easy integration with PLCs and flow computers

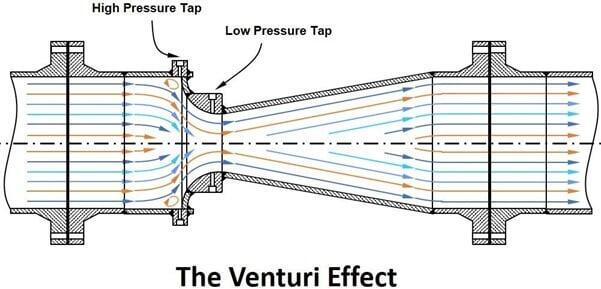

Custody-grade CNG flow measurement – Wyatt Engineering Venturi + SOR + Moore Industries

In some CNG custody-transfer projects—especially where plant standards favor differential-pressure (DP) metering or where you are upgrading an existing DP run—a Wyatt Engineering venturi tube with SOR Controls Group transmitters and Moore Industries temperature instrumentation provides a robust alternative to ultrasonic metering.

- A proven, fully mechanical primary element with no moving parts

- Low permanent pressure loss compared to many other DP devices

- Stable, predictable discharge coefficients for CNG custody-transfer calculations

- A well-defined meter run that can be sized and documented to recognized engineering practices

- SOR Controls Group differential pressure transmitter across the venturi to measure DP proportional to flow

- SOR line pressure transmitter for static pressure compensation and over-pressure monitoring

- Moore Industries temperature transmitter (head-mount or rail-mount) to bring process temperature into the custody-transfer calculation

- Optional Moore Industries signal conditioning to isolate, split, or convert signals for fiscal vs. operations paths

- Standard-volume CNG flow (SCFH/SCFM) based on DP, pressure, temperature, and gas properties

- Running and batch totals that align with custody-transfer contracts and invoice units

- You want to reuse existing DP-based engineering standards or metering practices

- Low pressure drop is important, but a full ultrasonic meter is not required or practical

- You prefer a primary element that is mechanically simple and easy to document for auditors and regulators

Supporting gas measurement – Kurz Instruments

- Mass flow monitoring on compressor discharge or suction lines

- Internal performance tracking for blowers, heaters, or process gas lines

- CNG load tracking where thermal mass is an acceptable technology

Pressure, temperature, and auxiliary signals

- Pressure transmitters for line pressure, over-pressure protection, and compensation

- Temperature transmitters to correct CNG volume to standard conditions

- Valve status and run/bypass feedback so you know exactly how the metering run was configured when totals were recorded

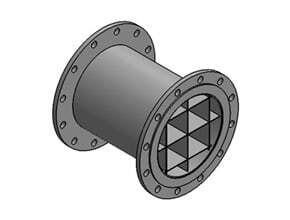

Flow conditioning: getting the profile right

- Flow Optimizers flow conditioning hardware helps:

- Create a stable, repeatable velocity profile at the meter

- Reduce the impact of elbows, tees, reducers, and other upstream disturbances

- Keep the meter operating within its published accuracy in a real-world layout

Control & tracking layer: turning signals into trusted totals

Once the CNG custody transfer meter run is in place, the next step is turning measurements into traceable totals and presenting them in a way that operators, accounting, and customers can all understand.

Toshiba PLCs & HMIs – the local custody-transfer engine

- Collect flow, pressure, and temperature signals from the meter run

- Execute contract-specific logic:

- Batch totals per trailer, tube skid, or delivery point

- Shift- or day-based closing totals

- Contract-specific rounding, thresholds, or alarms

- Present intuitive HMI screens for:

- Active transfers and historical batches

- Running totals and alarm conditions

- Operator notes or reason codes (e.g., meter bypassed, calibration in progress)

- Plant SCADA

- Data historians

- Customer or enterprise systems used for billing and reconciliation

Signal integrity & clean splits: Moore Industries

- Signal isolators and splitters provide multiple isolated copies of custody-transfer signals

- Separation between:

- The “fiscal” signal path used for custody transfer, reporting, and billing

- The “operations” path used for control loops, alarms, and optimization

- Safety-rated I/O where SIL or functional-safety requirements apply

What to define in your CNG custody-transfer project

To get a clean design and accurate budget for a CNG custody transfer tracking and data management solution, it helps to define a few key elements up front:

Process conditions

Line size, pressure, and temperature range

Gas composition and contaminants (moisture, particulates, etc.)

Normal, minimum, and peak flow rates; required turndown

Metering philosophy

New build vs. upgrade of a legacy turbine run

Preference for multipath ultrasonic vs. turbine or other technologies

Required uncertainty and applicable standards or contract language

Control and tracking requirements

Number of accounts, contracts, trailers, or delivery points to track

Batch-based vs. continuous custody transfer

Local vs. remote operator interfaces and acknowledgment needs

Data handoff and reporting

Which systems must receive custody-transfer totals (SCADA, historian, ERP, customer systems)

Cybersecurity and isolation requirements between domains

Required reports (daily closes, batch tickets, monthly summaries, audit trails)

Clipper Controls can help translate these requirements into a practical combination of Panametrics, Wyatt Engineering, SOR Controls Group, Kurz, Flow Optimizers, Toshiba, and Moore Industries products that fit your actual field layout and project constraints.

Work with a CNG custody transfer specialist

- Evaluate ultrasonic vs. turbine options for your CNG service

- Design meter runs with the right flow conditioning and diagnostics

- Specify PLC/HMI logic for batches, contracts, and audit-ready totals

- Integrate custody-transfer data cleanly into your existing control and business systems

👉 Ready to improve your CNG custody transfer tracking and data management?

Frequently Asked Questions

CNG custody transfer is the point where ownership of compressed natural gas passes from one party to another and every standard cubic foot is tied to revenue. Accurate custody-transfer systems help prevent disputes, support contracts and audits, and ensure that buyers and sellers have confidence in the measured quantity of gas.

CNG custody transfer typically occurs when gas moves from producers to midstream operators, when CNG is loaded into tube trailers or skids for over-the-road delivery, and when trailers or skids are unloaded at satellite or industrial stations. Each of these handoff points requires custody-grade metering and tracking.

Clipper Controls can design CNG custody-transfer systems around Panametrics Sentinel multipath ultrasonic flowmeters or a Wyatt Engineering venturi tube combined with SOR differential and line pressure transmitters and a Moore Industries temperature measurement. Both approaches provide custody-grade measurement with proper pressure, temperature, and flow conditioning.

Tracking and reporting are handled through Toshiba PLCs and touch-screen HMIs that collect signals from the custody-transfer meter run, apply batching and totals, and generate trailer-based and batch-based records. These systems can hand off validated totals to SCADA, historians, and business systems for billing, reconciliation, and audits.

You can work directly with a CNG custody-transfer specialist at Clipper Controls. Share your pipeline conditions, trailer or station configuration, required standards, and data tracking requirements, and the team can recommend a complete system including flow meter, flow conditioning, transmitters, PLC/HMI logic, and signal isolation and handoff.

Page Navigation Links

- Where CNG custody transfer happens

- Why CNG projects are moving from turbine to ultrasonic

- Measurement layer: CNG custody transfer starts at the meter run

- Flow conditioning: getting the profile right

- Control & tracking layer: turning signals into trusted totals

- Signal integrity & clean splits: Moore Industries

- What to define in your CNG custody-transfer project

- Work with a CNG custody transfer specialist

- Frequently Asked Questions