Plastic Liquid Level Switches for Corrosive and Clean Tanks

👉 Ready to enhance your level measurement program?

Contact Clipper Controls at (844) 880-2469 or message us to connect with an instrumentation expert.

Explore Similar Pages: Level Instrumentation | Capacitive Level Switches | Radar Level Transmitters | Process Controls | Water & Wastewater Process Control Applications | Refining & Chemical Process Control Applications | Food & Beverage Process Control Applications | Life Science Process Control Applications

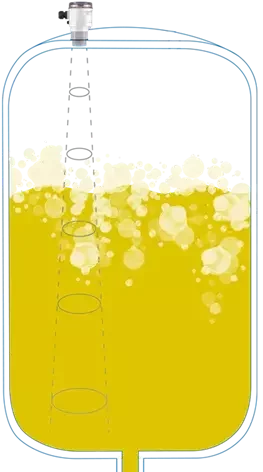

Why Plastic Liquid Level Switches Are Gaining Ground in Harsh Applications

Corrosion and Fouling: Why Metal Struggles

- Pitting and crevice corrosion in chloride-rich or oxidizing environments

- Stress corrosion cracking in certain chemical and temperature combinations

- Scaling and buildup from hard water, wastewater, or process solids

How Non-Metallic Designs Solve Common Failure Modes

- High chemical resistance in many acids, caustics, oxidizers, and salts

- No electrochemical or galvanic corrosion in mixed-metal systems

- Smoother surfaces that tend to foul less severely than some metallic finishes

- Lower risk of classic metal stress corrosion cracking mechanisms

Benefits in Water and Wastewater Treatment

- Disinfection chemical tanks – Sodium hypochlorite, sodium bisulfite, ammonia, and related chemicals that attack stainless steel

- Coagulant and polymer systems – Alum, ferric, and polymer tanks where fouling and corrosion are chronic issues

- Sumps, wet wells, and day tanks – Simple backups or alarms where mixed liquids, debris, and cleaning agents can be tough on metal components

- Reduce the frequency of float replacement and associated lock-out/tag-out work

- Minimize nuisance alarms caused by partially sticking floats

- Improve confidence in high-level and low-level interlocks tied to pump control and overfill prevention

Expanding Into Process and OEM Environments

- Chemical processing and bulk storage – Corrosive storage tanks and scrubbers

- OEM skids and packages – Compact plastic level switches for OEM equipment used across standardized skids

- High-purity or specialty systems – Semiconductor, biotech, and specialty chemical systems that prefer non-metallic wetted parts

👉 Need help deciding where plastic makes sense over stainless?

Contact Clipper Controls at (844) 880-2469 or message us to review your tank-level applications.

Plastic vs Stainless Steel: Benefits and Tradeoffs for Float Level Switches

Corrosion and Chemical Compatibility

- Oxidizing chemicals (e.g., bleach, peroxide-based cleaners)

- Chloride-rich environments common in many industrial processes

- Certain acids and mixed chemicals where corrosion mechanisms are complex

- Use plastics that are inherently chemical-resistant (PP, PVC, PVDF, etc.)

- Avoid galvanic and electrochemical corrosion entirely

- Often tolerate splash zones and vapors that attack metal components first

Temperature, Pressure, and Mechanical Limits

- Process temperatures are high

- Tanks operate at elevated pressure or deep vacuum

- Mechanical abuse is likely: heavy vibration, impacts, frequent handling

- Lower maximum temperature ratings than stainless

- More sensitivity to mechanical stress, over-torquing, and pipe strain

- Potential softening or deformation at higher temperatures

- If your primary concern is corrosion and chemical attack in ambient or moderate-temperature tanks → plastic is often the better starting point.

- If the application is defined by high temperature, high pressure, or heavy mechanical loads → stainless (or another metal) is usually the safer default.

Safety, Compliance, and Food/Pharma Considerations

- CIP and cleaning chemical tanks

- Non-product-contact utility and waste tanks

- Cleaning and buffer chemical storage

- Waste collection and neutralization tanks

- Utility systems and non-product-contact vessels

Key Design Choices: Mounting, Orientation, and Electrical Configurations

Vertical vs Horizontal / Side-Mount Level Switches

- Best for deep tanks, sumps, and stilling wells

- Well suited to multi-point control (high/low, pump on/off, alarms)

- Less exposed to side loads from external piping

- Ideal when top access is limited or obstructed

- Useful for retrofits where adding a side nozzle is easier than modifying the tank top

- Effective as compact, single-point liquid level control switches at a specific elevation

Single-Point vs Multi-Point Control

- Single-point switches – High- or low-level alarms, simple pump protection, compact OEM applications

- Multi-point switches – Several switching levels on one stem for combined alarm and pump control, reducing the number of tank penetrations

Compact Level Switches for Tanks and OEM Equipment

- Small header and day tanks

- Chemical feed tanks on tight skid frames

- Skids with limited overhead clearance

- Overall length and insertion depth

- Minimum tank opening size

- Orientation flexibility (float flip for N.O./N.C.)

- Connector or cable options that simplify wiring

Electrical Options and Control System Integration

- SPST (N.O. or N.C.) and SPDT contact configurations

- Direct connection to PLC digital inputs or relay panels

- Flexibility in implementing failsafe and alarm logic

👉 Not sure which mounting style fits your tank?

Matching Plastic Materials to Media: Chemical Compatibility 101

Common Plastic Materials in Level Switches

- Polypropylene (PP) – Common, cost-effective, good for many acids/caustics and water/wastewater chemicals

- Polyvinyl Chloride (PVC) – Widely used in piping; suitable for many acids and alkalis at moderate temperatures

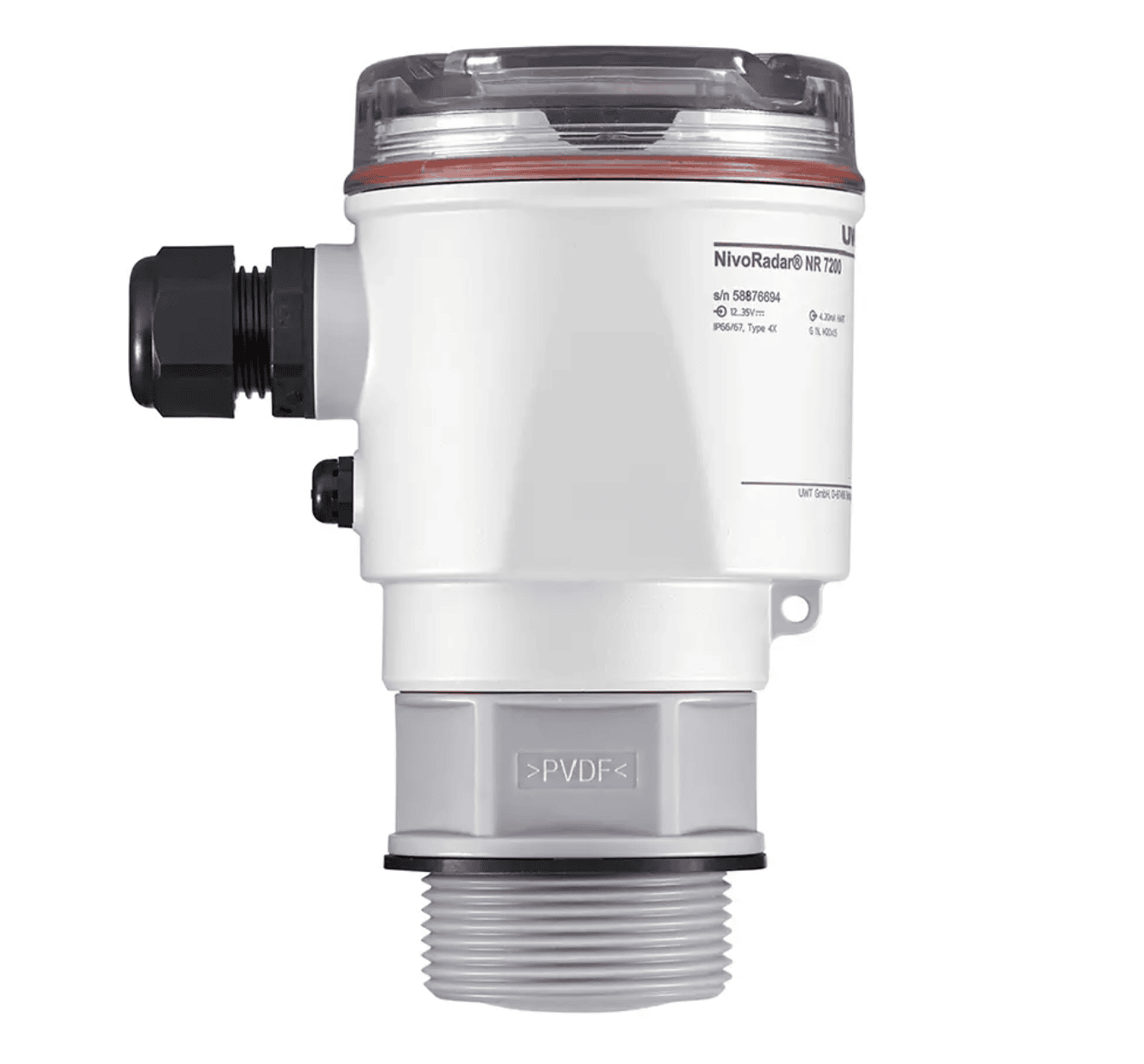

- Polyvinylidene Fluoride (PVDF) – High-performance; excellent resistance to strong acids, oxidizers, and higher temperatures

- Other fluoropolymers (e.g., PFA) – Premium materials for very aggressive or high-purity chemistries

Using Chemical Compatibility Charts (Without Becoming a Chemist)

- Identify the exact chemical(s) and concentration.

- Confirm operating and upset temperature ranges.

- Review the manufacturer’s compatibility data for PP, PVC, PVDF, etc.

- Consider vapor and splash exposure, not just liquid contact.

- Be conservative when conditions are close to material limits.

Mechanical and Environmental Factors

- Temperature cycling and thermal expansion

- Tank material and wall thickness (especially plastic and fiberglass)

- UV exposure for outdoor tanks

- Cleaning and washdown practices

- Solids, scaling, and buildup that may restrict float movement

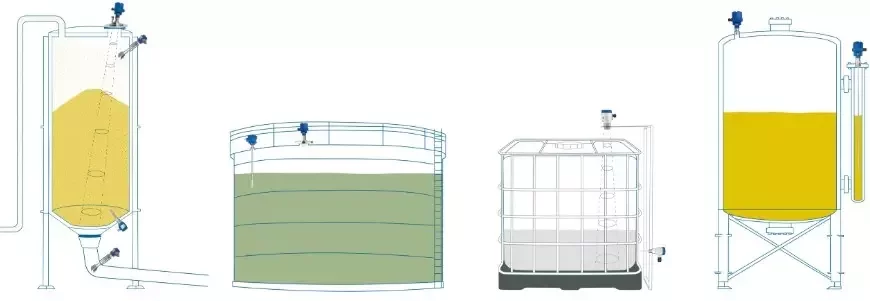

Application Examples: Where Plastic Liquid Level Switches Excel

Water and Wastewater Treatment Plants

- Disinfection chemical tanks (bleach, bisulfite, ammonia)

- Coagulant and polymer tanks (alum, ferric, polymer solutions)

- Sumps, wet wells, and day tanks for backup alarms and pump protection

Chemical Processing and Bulk Storage

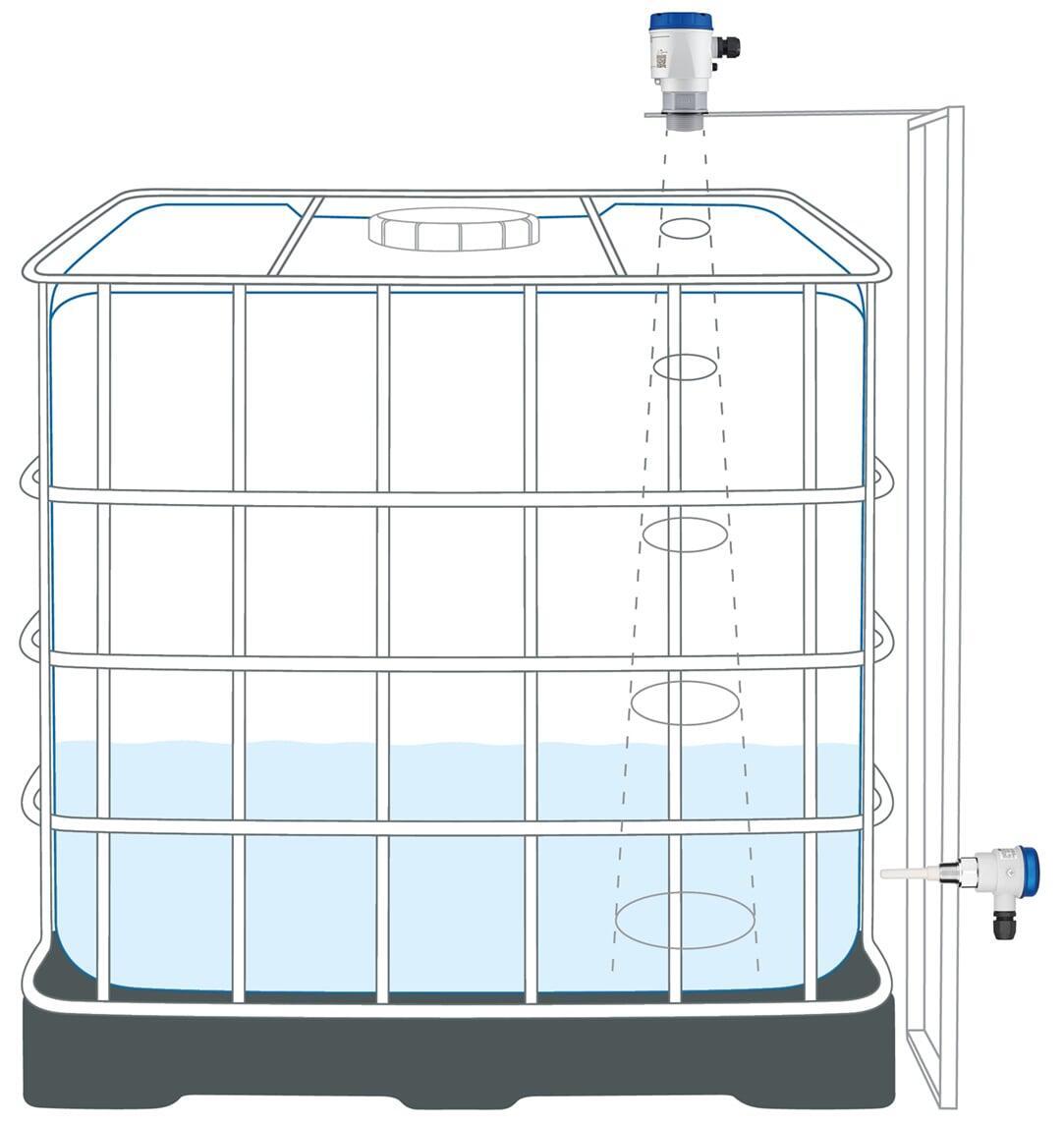

- Bulk storage tanks and IBC totes use plastic switches for high-level alarms and overfill prevention.

- Day tanks and feed tanks rely on non-metallic liquid level switch designs for pump control.

- Scrubbers and neutralization systems use plastic switches in mixed, often harsh chemistries.

Food and Beverage Tanks

- CIP and cleaning chemical tanks

- Utility and service water tanks

- Waste and non-product-contact vessels

Pharmaceutical and Biotech Vessels

- Cleaning and buffer chemical tanks

- Waste collection and neutralization tanks

- Utility and support skids

Semiconductor Chemical Delivery Systems

- Non-metallic wetted parts support high-purity and ultra-corrosive chemistries.

- Compact switches fit in tight chemical cabinets and day tanks.

- PVDF and fluoropolymer construction aligns with stringent compatibility requirements.

OEM Skids and Packaged Systems

- Chemical feed and dosing skids can standardize on compact plastic level switches for OEM equipment across different chemistries.

- Water treatment and filtration skids use plastic switches for process and waste tanks.

- Utility and HVAC skids benefit from consistent, easy-to-wire level hardware.

👉 Designing a new skid or upgrading plant tanks?

Clipper Controls can recommend plastic level switches tailored to your industry.

UWT Plastic Liquid Level Switch Solutions from Clipper Controls

Selecting the right plastic liquid level switches isn’t only about materials and mounting styles—it’s also about choosing proven product families. Clipper Controls works closely with UWT to provide plastic level switch solutions that fit real-world plant conditions.

UWT Plastic Float Switches for Corrosive Media

- Chemical storage and day tanks

- Water and wastewater chemical dosing systems

- Utility and process sumps

How Clipper Controls Adds Value

- Media and materials review for proper chemical compatibility

- Mounting style and form factor selection (vertical, side-mount, compact)

- Control-system alignment (contacts, ratings, wiring guidance)

- Support for standardization programs across plants or OEM product lines

Installation and Maintenance Best Practices for Plastic Level Switches

Even the best-specified plastic liquid level switches can underperform if they’re installed or maintained incorrectly.

Mounting and Mechanical Considerations

- Use proper torque on plastic threads—avoid over-tightening.

- Choose sealants compatible with plastics (PTFE tape or approved sealants).

- Support external piping and conduits so the switch isn’t a structural member.

- Match mounting hardware to tank material and wall thickness, especially for plastic and fiberglass tanks.

Electrical and Control Checks

- Verify contact operation by manually actuating the float.

- Document and confirm N.O./N.C. behavior.

- Protect reed contacts from overload by using interposing relays when needed.

Inspection and Maintenance Routines

- Periodic visual inspection for discoloration, swelling, cracking, or damage.

- Check for buildup and verify free float movement, especially in scaling services.

- Functional testing during planned outages to confirm alarms and control actions.

Specification Checklist: How to Choose Plastic Liquid Level Switches for Chemical Tanks

When you’re specifying plastic liquid level switches for chemical tanks, a structured checklist keeps projects moving and reduces rework.

1. Process Fluid and Operating Conditions

- Normal and upset temperatures

- Pressure conditions and venting

- Vapor, splash, and washdown exposure

2. Tank Construction and Geometry

- Tank material and any internal lining

- Tank size, shape, and internals (baffles, mixers, etc.)

- Existing or planned nozzles and openings

3. Mounting Style and Switching Points

- Top, side, or external chamber mounting

- Single-point vs multi-point requirements

- Functional roles: alarms, pump start/stop, protection trips

4. Electrical Interface and Control Logic

- PLC/relay system details and input types

- SPST vs SPDT contact requirements

- Load characteristics and failsafe philosophy

5. Standards, Approvals, and Site Preferences

- Plant or corporate standards and preferred manufacturers

- Any relevant safety or regulatory requirements

- Spares and standardization strategy across tanks and sites

How Clipper Controls Helps Engineers and Maintenance Teams Standardize Level Switches

Application Engineering, Not Just Part Numbers

- Process review (chemicals, tanks, environment)

- Functional requirements (alarms, pump control, interlocks)

- Material and mounting recommendations tailored to each service

Support Across Industries and Project Types

- Water and wastewater treatment

- Chemical processing and bulk storage

- Food and beverage utilities and CIP systems

- Pharmaceutical and biotech utilities and waste

- Semiconductor chemical delivery systems

- OEM skids and packaged systems

👉 We support projects across California, Nevada, and Hawaii with local engineering, calibration, and field integration.

Frequently Asked Questions

A plastic liquid level switch is a point-level device with plastic wetted parts, typically using either a buoyant float with an internal reed switch or a solid-state capacitive sensor to detect when liquid reaches a set level in a tank, sump, or vessel.

They’re widely used in chemical storage tanks, water and wastewater treatment systems, CIP and cleaning tanks, utility and waste vessels, and OEM skids where corrosion resistance is important.

Choose plastic liquid level switches when corrosion and chemical attack are the main concerns and temperatures and pressures are moderate; stainless is better for high-temperature, high-pressure, or heavy mechanical-duty applications.

Yes—many plastic float level switches use materials like PP, PVC, or PVDF that withstand acids, caustics, oxidizers, and salts, but compatibility must be checked against your specific chemical, concentration, and temperature.

Plastic level switches are available as vertical float level switches mounted from the top of the tank and horizontal / side-mount level switches installed through the sidewall, in both single-point and multi-point configurations.

You’ll get the best result by providing the process fluid, concentration, temperature, tank material and nozzle details, desired mounting style, number of switching points, and basic control-system information (PLC vs. relay, voltage, contact type).

Clipper Controls represents UWT plastic liquid level switches for chemical tanks, and provides local application engineering to match materials, mounting, and electrical options to your tanks, chemicals, and control systems.

Page Navigation Links

- Why Plastic Liquid Level Switches Are Gaining Ground in Harsh Applications

- Plastic vs Stainless Steel: Benefits and Tradeoffs for Float Level Switches

- Key Design Choices: Mounting, Orientation, and Electrical Configurations

- Matching Plastic Materials to Media: Chemical Compatibility 101

- Application Examples: Where Plastic Liquid Level Switches Excel

- UWT Plastic Liquid Level Switch Solutions from Clipper Controls

- Installation and Maintenance Best Practices for Plastic Level Switches

- Specification Checklist: How to Choose Plastic Liquid Level Switches for Chemical Tanks

- How Clipper Controls Helps Engineers and Maintenance Teams Standardize Level Switches

- Frequently Asked Questions