Electronic Temperature Monitor (ETM) for Oil-Filled Transformers

👉 We support customers across California, Nevada, and Hawaii with application help, startup/commissioning guidance, and the right transformer ETM selection for your needs. Contact us today!

Similar Pages: Power Monitoring Equipment

What is a transformer temperature monitor?

- Oil temperature measurement (commonly top oil; sometimes bottom oil/ambient too)

- Winding temperature indication via:

- Simulated winding temperature (using a heated thermowell approach), or

- Calculated winding temperature (using oil temperature + load current + transformer parameters)

- Cooling control logic (multi-stage fan/pump control, timers/exercise, seasonal modes)

- Alarm/trip relays (configurable setpoints, delays, fail-safe behavior)

- Signals/comms for SCADA (analog outputs and/or protocols like Modbus/DNP3)

ETM vs OTI/WTI vs “transformer monitor”

- OTI (Oil Temperature Indicator): traditionally indicates top-oil temperature and may provide alarm/control contacts.

- WTI (Winding Temperature Indicator): traditionally indicates winding temperature (often via a thermal replica concept and/or current influence) and may provide alarm/control contacts.

- ETM (Electronic Temperature Monitor): typically replaces or modernizes OTI/WTI functions, adds configurability, data outputs, event/history, and communications.

Why temperature (especially winding hot-spot) is the limiting factor

How ETMs determine oil and winding temperature

Oil temperature (direct measurement)

Most ETMs use platinum RTD probes installed in a thermowell to directly measure oil temperature. Depending on the transformer and the monitoring objective, the measured point may be top oil (most common), bottom oil, or sometimes ambient for context and control logic.

Winding temperature (simulated vs calculated)

- Simulated winding temperature (simple, retrofit-friendly)

A common method uses a heated thermowell arrangement so the instrument can simulate winding rise based on measured oil temperature. - Calculated winding temperature (CT-based thermal model)

A more data-driven method measures oil temperature and load current (often from an existing CT) and uses transformer parameters to calculate winding temperature. This approach is designed to better reflect how winding temperature behaves under changing load and cooling conditions.

Cooling control: what ETMs do day-to-day

- Stage cooling: turn fans/pumps on in steps to control temperature without excessive cycling

- Protect the asset: alarm and trip outputs for high temperature, sensor faults, or abnormal conditions

- Operational polish: fan exercise timers, seasonal setbacks, and control logic that matches site practices

- Visibility: send key temperatures, status, and alarms into SCADA so operators don’t fly blind

Where ETMs are used

- Utility substations and distribution yards:

ETMs help operators manage transformer loading and thermal limits by monitoring top-oil and winding temperature, staging fan/pump cooling, and reporting status to SCADA for dispatch and maintenance planning. - Power generation and plant electrical systems:

From auxiliary transformers to station service equipment, ETMs support reliable operation with configurable alarming and cooling control—useful in environments where load profiles change and temperature limits are tightly managed. - Industrial facilities with critical power infrastructure:

Refineries, chemical plants, water/wastewater facilities, mining, and large manufacturing sites use ETMs to protect process uptime, coordinate cooling control, and integrate transformer temperature and alarms into plant control systems. - Retrofit upgrades on legacy transformers (OTI/WTI replacement):

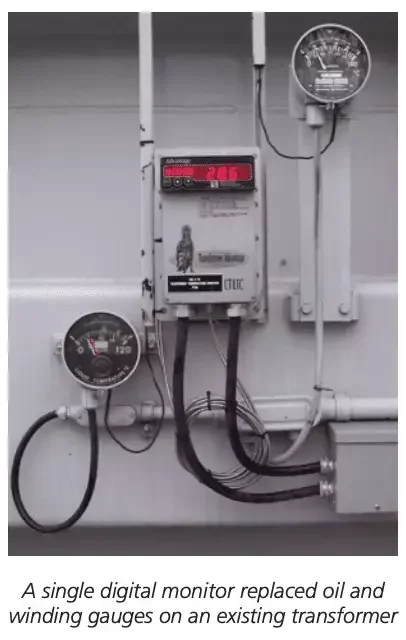

ETMs are a common upgrade path when analog oil and winding gauges are aging, hard to source, or not providing the visibility modern operations need. A retrofit ETM can modernize monitoring and add outputs/communications without requiring a full transformer condition-monitoring package.

👉 Not sure which ETM approach fits your site? Message us, we're happy to help!

Common ETM configurations (“what do I actually need?”)

- Measures: Top-oil temperature (RTD)

- Typical use: Smaller transformers, stable loads, or basic monitoring needs

- Common outputs: Local display + alarm relays (optional analog output)

- Measures/indicates: Top-oil temperature + simulated winding temperature

- Typical use: Retrofits replacing analog OTI/WTI where CT access isn’t available or desired

- Common outputs: Cooling stage control relays + alarm/trip relays (optional SCADA/analog)

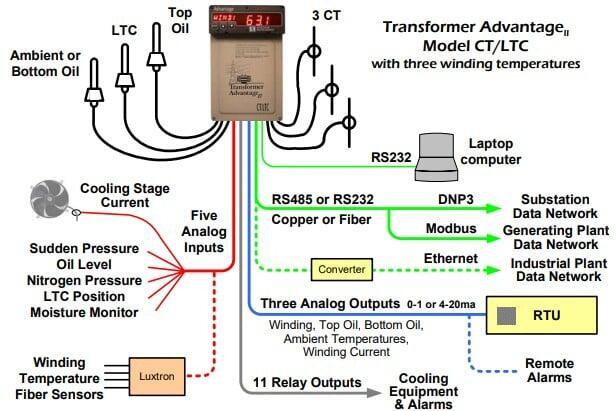

- Measures/calculates: Top-oil temperature + calculated winding temperature using CT inputs

- Typical use: Utility substations, generation, and critical industrial power where thermal limits matter

- Common outputs: Multi-stage fan/pump control, alarm/trip relays, and SCADA communications (Modbus/DNP3)

- Measures: Top oil + ambient or bottom oil (and other points as needed)

- Typical use: Outdoor installations with large seasonal swings or transformers sensitive to ambient conditions

- Common outputs: Additional analog outputs/logging for trending and diagnostics

- Monitors: LTC-related temperature difference (model-dependent)

- Typical use: Assets where LTC behavior/position is part of operational troubleshooting

- Common outputs: Alarms/logging tied to LTC temperature difference thresholds

What to specify when selecting an ETM

- How many temperature points? (Top oil only, oil + winding, oil + winding + ambient/bottom oil)

- RTD type/wiring and physical installation (thermowell vs external/magnetic mounting if applicable)

Winding method

- Simulated winding or calculated winding?

- If calculated: CT details (secondary current range, installation approach), transformer cooling class, and key nameplate/thermal parameters

- Number of cooling stages (fans/pumps), control strategy, and any special logic (exercise timer, seasonal mode)

- Relay count needed for alarms/trips/control/fail-safe behavior

- Any readback of cooling status you want to capture (proof that cooling actually ran)

- Analog outputs required (4–20 mA channels, what each channel represents)

- SCADA protocol needs (Modbus and/or DNP3), plus physical layer needs (serial vs Ethernet/fiber)

- Enclosure rating and mounting style (yard-mounted, panel-mounted, sunlight, weather exposure)

- EMI/RFI expectations typical of substation environments

Weschler Instruments ETMs

If you want a concrete, well-scoped ETM example to reference (and a clean option for new builds or retrofits), Weschler’s Transformer Advantage line is explicitly positioned as ETMs for oil-filled transformers.

👉 If you’re replacing aging OTI/WTI gauges, modernizing cooling control, or bringing transformer temperatures into SCADA, the Weschler Transformer Advantage 2 and 3 ETMs are purpose-built for that thermal mission—without turning the project into a full condition-monitoring overhaul.

Transformer Advantage 2 (ETM)

- A proven ETM platform focused on oil temperature + winding indication + cooling control

- Flexible setpoints/relays and optional communications (typical substation/industrial integration needs)

- Retrofit-friendly options (including configurations intended to replace oil and winding gauges)

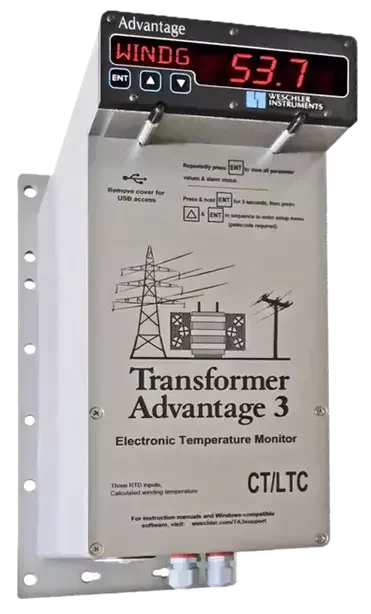

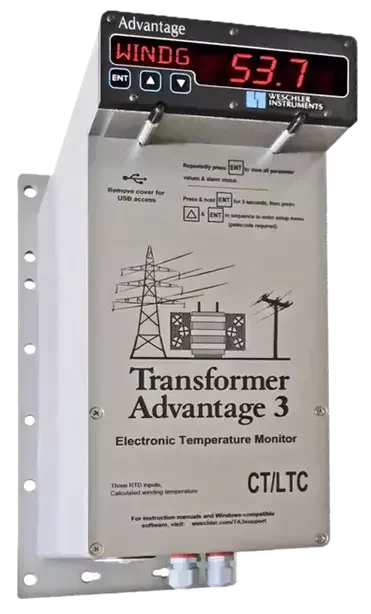

Transformer Advantage 3 (ETM)

- More I/O headroom (relays + analog outputs) for complex alarming/cooling/control schemes

- Expanded comms options for modern SCADA/networking expectations

- A current-generation platform for new installs or standardization programs

Quick Comparison (high-level)

Transformer Advantage ETM Comparison

| Feature | Transformer Advantage 2 | Transformer Advantage 3 |

|---|---|---|

| Primary use | ETM for oil-filled transformers | Newest-generation ETM for oil-filled transformers |

| Winding indication | Simulated and/or calculated models (by configuration) | Simulated and/or calculated (by model), with expanded platform |

| Cooling control | Multi-stage cooling control (by configuration) | Multi-stage cooling control; designed for expanded control/IO needs |

| Relays / outputs | Model/options dependent | Highlights up to 12 relays and up to 4 analog outputs |

| Communications | Options commonly include Modbus/DNP3 (by model/options) | Expanded comms options; highlights fiber Ethernet capability |

Talk to a Transformer ETM Specialist

Explore Related Pages: Power Monitoring Equipment | Energy Product Applications | Refining & Chemical Product Applications | Landfill Product Applications | Wastewater Product Applications | Environmental Monitoring Systems

Supporting System: Equipment Shelters | Fiberglass (FRP) Shelters | Industrial Gas Detectors | Calibration Service

FAQ

In this context, ETM means Electronic Temperature Monitor—a device focused on transformer thermal monitoring (oil temperature + winding indication) and thermal management (cooling control, alarms, and optional SCADA integration).

An ETM often replaces or modernizes the functions of traditional OTI (oil temperature indicator) and WTI (winding temperature indicator) by adding electronic configurability, logging, outputs, and communications.

Many ETMs calculate winding temperature using oil temperature + load current + transformer parameters and a thermal model that accounts for cooling mode and time constants. This improves tracking under changing loads compared with a single steady-state assumption.

Typically, yes—calculated winding temperature methods require a load current input (often from an existing CT). If you don’t have CT access or want simpler installation, simulated winding configurations may be more practical.

It depends on your SCADA environment. DNP3 is common in many utility contexts; Modbus is common across industrial control. The best answer is: pick what your existing system supports cleanly and standardize wherever possible.

Often, yes. Many ETM configurations are designed specifically to modernize or replace analog oil and winding indicators, while adding better control logic and integration options.

Page Navigation Links

- What is a transformer temperature monitor?

- ETM vs OTI/WTI vs “transformer monitor”

- Why temperature (especially winding hot-spot) is the limiting factor

- How ETMs determine oil and winding temperature

- Cooling control: what ETMs do

- Where ETMS are used

- Common ETM configurations (“what do I actually need?”)

- What to specify for an ETM

- Weschler Instruments ETMs

- Talk to a Transformer ETM Specialist

- FAQ